PDF Publication Title:

Text from PDF Page: 002

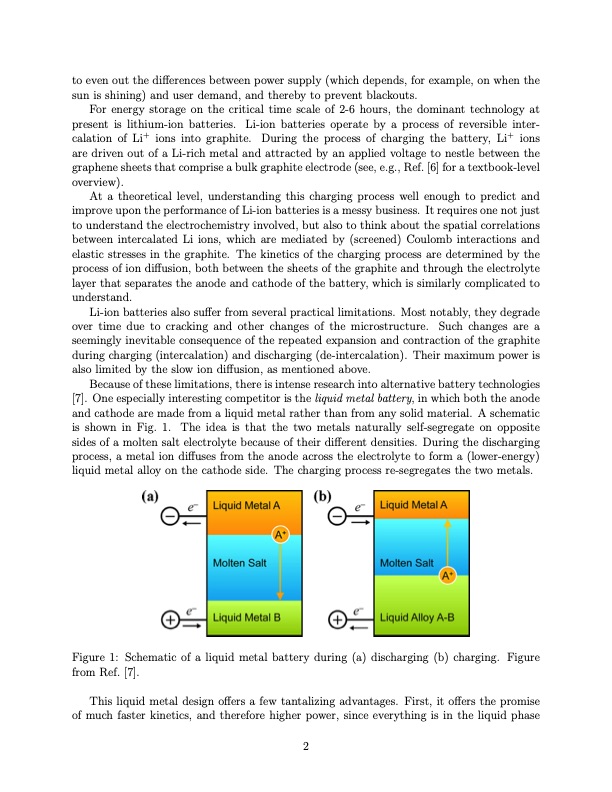

to even out the differences between power supply (which depends, for example, on when the sun is shining) and user demand, and thereby to prevent blackouts. For energy storage on the critical time scale of 2-6 hours, the dominant technology at present is lithium-ion batteries. Li-ion batteries operate by a process of reversible inter- calation of Li+ ions into graphite. During the process of charging the battery, Li+ ions are driven out of a Li-rich metal and attracted by an applied voltage to nestle between the graphene sheets that comprise a bulk graphite electrode (see, e.g., Ref. [6] for a textbook-level overview). At a theoretical level, understanding this charging process well enough to predict and improve upon the performance of Li-ion batteries is a messy business. It requires one not just to understand the electrochemistry involved, but also to think about the spatial correlations between intercalated Li ions, which are mediated by (screened) Coulomb interactions and elastic stresses in the graphite. The kinetics of the charging process are determined by the process of ion diffusion, both between the sheets of the graphite and through the electrolyte layer that separates the anode and cathode of the battery, which is similarly complicated to understand. Li-ion batteries also suffer from several practical limitations. Most notably, they degrade over time due to cracking and other changes of the microstructure. Such changes are a seemingly inevitable consequence of the repeated expansion and contraction of the graphite during charging (intercalation) and discharging (de-intercalation). Their maximum power is also limited by the slow ion diffusion, as mentioned above. Because of these limitations, there is intense research into alternative battery technologies [7]. One especially interesting competitor is the liquid metal battery, in which both the anode and cathode are made from a liquid metal rather than from any solid material. A schematic is shown in Fig. 1. The idea is that the two metals naturally self-segregate on opposite sides of a molten salt electrolyte because of their different densities. During the discharging process, a metal ion diffuses from the anode across the electrolyte to form a (lower-energy) liquid metal alloy on the cathode side. The charging process re-segregates the two metals. Figure 1: Schematic of a liquid metal battery during (a) discharging (b) charging. Figure from Ref. [7]. This liquid metal design offers a few tantalizing advantages. First, it offers the promise of much faster kinetics, and therefore higher power, since everything is in the liquid phase 2PDF Image | Liquid metal batteries and their magnetohydrodynamic instabilities

PDF Search Title:

Liquid metal batteries and their magnetohydrodynamic instabilitiesOriginal File Name Searched:

JCCM_January_2022_02.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |