PDF Publication Title:

Text from PDF Page: 003

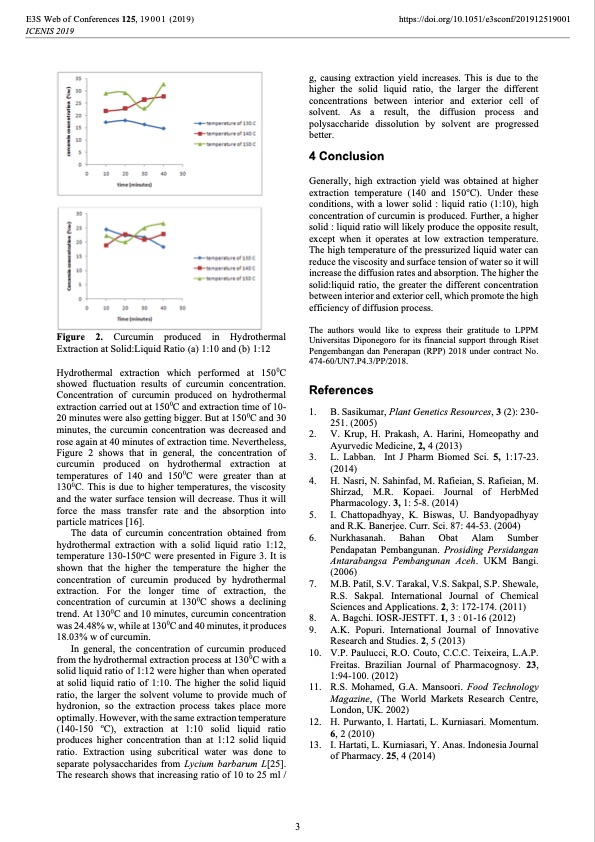

E3S Web of Conferences 125, 19001 (2019) ICENIS 2019 Figure 2. Curcumin produced in Hydrothermal Extraction at Solid:Liquid Ratio (a) 1:10 and (b) 1:12 Hydrothermal extraction which performed at 1500C showed fluctuation results of curcumin concentration. Concentration of curcumin produced on hydrothermal extraction carried out at 1500C and extraction time of 10- 20 minutes were also getting bigger. But at 1500C and 30 minutes, the curcumin concentration was decreased and rose again at 40 minutes of extraction time. Nevertheless, Figure 2 shows that in general, the concentration of curcumin produced on hydrothermal extraction at temperatures of 140 and 1500C were greater than at 1300C. This is due to higher temperatures, the viscosity and the water surface tension will decrease. Thus it will force the mass transfer rate and the absorption into particle matrices [16]. The data of curcumin concentration obtained from hydrothermal extraction with a solid liquid ratio 1:12, temperature 130-150oC were presented in Figure 3. It is shown that the higher the temperature the higher the concentration of curcumin produced by hydrothermal extraction. For the longer time of extraction, the concentration of curcumin at 1300C shows a declining trend. At 1300C and 10 minutes, curcumin concentration was 24.48% w, while at 1300C and 40 minutes, it produces 18.03% w of curcumin. In general, the concentration of curcumin produced from the hydrothermal extraction process at 1300C with a solid liquid ratio of 1:12 were higher than when operated at solid liquid ratio of 1:10. The higher the solid liquid ratio, the larger the solvent volume to provide much of hydronion, so the extraction process takes place more optimally. However, with the same extraction temperature (140-150 oC), extraction at 1:10 solid liquid ratio produces higher concentration than at 1:12 solid liquid ratio. Extraction using subcritical water was done to separate polysaccharides from Lycium barbarum L[25]. The research shows that increasing ratio of 10 to 25 ml / https://doi.org/10.1051/e3sconf/201912519001 g, causing extraction yield increases. This is due to the higher the solid liquid ratio, the larger the different concentrations between interior and exterior cell of solvent. As a result, the diffusion process and polysaccharide dissolution by solvent are progressed better. 4 Conclusion Generally, high extraction yield was obtained at higher extraction temperature (140 and 150oC). Under these conditions, with a lower solid : liquid ratio (1:10), high concentration of curcumin is produced. Further, a higher solid : liquid ratio will likely produce the opposite result, except when it operates at low extraction temperature. The high temperature of the pressurized liquid water can reduce the viscosity and surface tension of water so it will increase the diffusion rates and absorption. The higher the solid:liquid ratio, the greater the different concentration between interior and exterior cell, which promote the high efficiency of diffusion process. The authors would like to express their gratitude to LPPM Universitas Diponegoro for its financial support through Riset Pengembangan dan Penerapan (RPP) 2018 under contract No. 474-60/UN7.P4.3/PP/2018. References 1. B. Sasikumar, Plant Genetics Resources, 3 (2): 230- 251. (2005) 2. V. Krup, H. Prakash, A. Harini, Homeopathy and Ayurvedic Medicine, 2, 4 (2013) 3. L. Labban. Int J Pharm Biomed Sci. 5, 1:17-23. (2014) 4. H. Nasri, N. Sahinfad, M. Rafieian, S. Rafieian, M. Shirzad, M.R. Kopaei. Journal of HerbMed Pharmacology. 3, 1: 5-8. (2014) 5. I. Chattopadhyay, K. Biswas, U. Bandyopadhyay and R.K. Banerjee. Curr. Sci. 87: 44-53. (2004) 6. Nurkhasanah. Bahan Obat Alam Sumber Pendapatan Pembangunan. Prosiding Persidangan Antarabangsa Pembangunan Aceh. UKM Bangi. (2006) 7. M.B. Patil, S.V. Tarakal, V.S. Sakpal, S.P. Shewale, R.S. Sakpal. International Journal of Chemical Sciences and Applications. 2, 3: 172-174. (2011) 8. A. Bagchi. IOSR-JESTFT. 1, 3 : 01-16 (2012) 9. A.K. Popuri. International Journal of Innovative Research and Studies. 2, 5 (2013) 10. V.P. Paulucci, R.O. Couto, C.C.C. Teixeira, L.A.P. Freitas. Brazilian Journal of Pharmacognosy. 23, 1:94-100. (2012) 11. R.S. Mohamed, G.A. Mansoori. Food Technology Magazine, (The World Markets Research Centre, London, UK. 2002) 12. H. Purwanto, I. Hartati, L. Kurniasari. Momentum. 6, 2 (2010) 13. I. Hartati, L. Kurniasari, Y. Anas. Indonesia Journal of Pharmacy. 25, 4 (2014) 3PDF Image | Curcumin Extracted from Turmeric by Hydrothermal Extraction

PDF Search Title:

Curcumin Extracted from Turmeric by Hydrothermal ExtractionOriginal File Name Searched:

curcumin-hydrothermal-extraction.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |