PDF Publication Title:

Text from PDF Page: 037

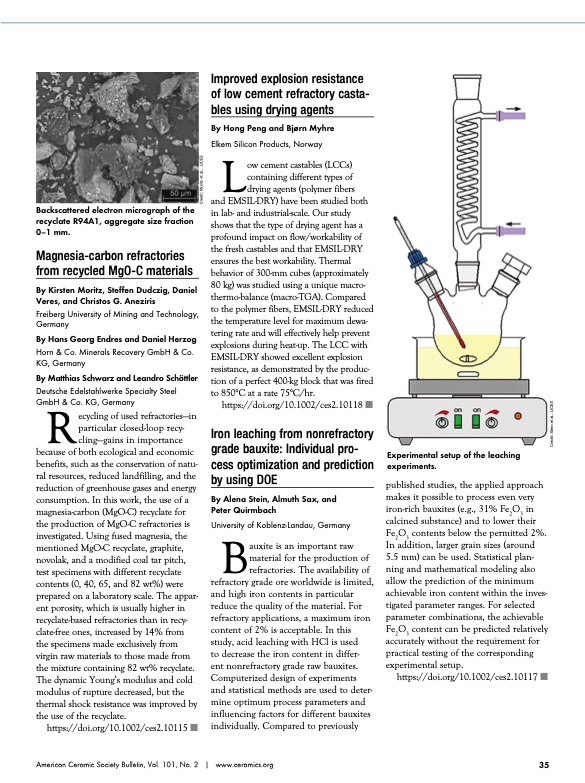

Backscattered electron micrograph of the recyclate R94A1, aggregate size fraction 0–1 mm. Magnesia-carbon refractories from recycled MgO-C materials By Kirsten Moritz, Steffen Dudczig, Daniel Veres, and Christos G. Aneziris Freiberg University of Mining and Technology, Germany By Hans Georg Endres and Daniel Herzog Horn & Co. Minerals Recovery GmbH & Co. KG, Germany By Matthias Schwarz and Leandro Schöttler Deutsche Edelstahlwerke Specialty Steel GmRbH & Co. KG, Germany ecycling of used refractories—in particular closed-loop recy- cling—gains in importance because of both ecological and economic benefits, such as the conservation of natu- ral resources, reduced landfilling, and the reduction of greenhouse gases and energy consumption. In this work, the use of a magnesia-carbon (MgO-C) recyclate for the production of MgO-C refractories is investigated. Using fused magnesia, the mentioned MgO-C recyclate, graphite, novolak, and a modified coal tar pitch, test specimens with different recyclate contents (0, 40, 65, and 82 wt%) were prepared on a laboratory scale. The appar- ent porosity, which is usually higher in recyclate-based refractories than in recy- clate-free ones, increased by 14% from the specimens made exclusively from virgin raw materials to those made from the mixture containing 82 wt% recyclate. The dynamic Young’s modulus and cold modulus of rupture decreased, but the thermal shock resistance was improved by the use of the recyclate. https://doi.org/10.1002/ces2.10115 n American Ceramic Society Bulletin, Vol. 101, No. 2 Improved explosion resistance of low cement refractory casta- bles using drying agents By Hong Peng and Bjørn Myhre Elkem Silicon Products, Norway Low cement castables (LCCs) containing different types of drying agents (polymer fibers and EMSIL-DRY) have been studied both in lab- and industrial-scale. Our study shows that the type of drying agent has a profound impact on flow/workability of the fresh castables and that EMSIL-DRY ensures the best workability. Thermal behavior of 300-mm cubes (approximately 80 kg) was studied using a unique macro- thermo-balance (macro-TGA). Compared to the polymer fibers, EMSIL-DRY reduced the temperature level for maximum dewa- tering rate and will effectively help prevent explosions during heat-up. The LCC with EMSIL-DRY showed excellent explosion resistance, as demonstrated by the produc- tion of a perfect 400-kg block that was fired to 850°C at a rate 75°C/hr. https://doi.org/10.1002/ces2.10118 n Iron leaching from nonrefractory grade bauxite: Individual pro- cess optimization and prediction by using DOE By Alena Stein, Almuth Sax, and Peter Quirmbach University of Koblenz-Landau, Germany Experimental setup of the leaching experiments. B refractory grade ore worldwide is limited, and high iron contents in particular reduce the quality of the material. For refractory applications, a maximum iron content of 2% is acceptable. In this study, acid leaching with HCl is used to decrease the iron content in differ- ent nonrefractory grade raw bauxites. Computerized design of experiments and statistical methods are used to deter- mine optimum process parameters and influencing factors for different bauxites individually. Compared to previously | www.ceramics.org Fe2O3 contents below the permitted 2%. In addition, larger grain sizes (around 5.5 mm) can be used. Statistical plan- ning and mathematical modeling also allow the prediction of the minimum achievable iron content within the inves- tigated parameter ranges. For selected parameter combinations, the achievable auxite is an important raw material for the production of refractories. The availability of published studies, the applied approach makes it possible to process even very iron-rich bauxites (e.g., 31% Fe O in 23 calcined substance) and to lower their Fe O content can be predicted relatively 23 accurately without the requirement for practical testing of the corresponding experimental setup. https://doi.org/10.1002/ces2.10117 n 35 Credit: Stein et al., IJCES Credit: Moritz et al., IJCESPDF Image | hydrogen as an alternative fuel

PDF Search Title:

hydrogen as an alternative fuelOriginal File Name Searched:

March2022.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |