PDF Publication Title:

Text from PDF Page: 003

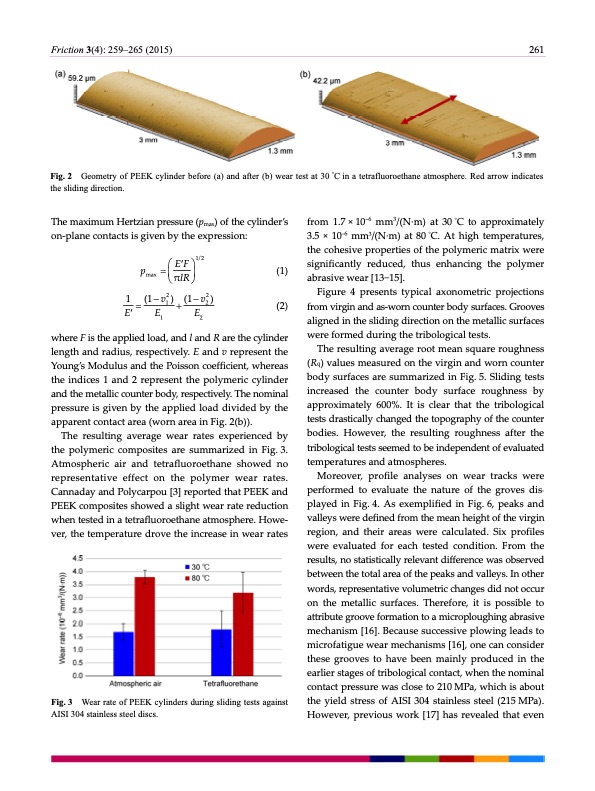

Friction 3(4): 259–265 (2015) 261 Fig. 2 Geometry of PEEK cylinder before (a) and after (b) wear test at 30 °C in a tetrafluoroethane atmosphere. Red arrow indicates the sliding direction. The maximum Hertzian pressure (pmax) of the cylinder’s on-plane contacts is given by the expression: EF 1/2 pmax (1) from 1.7 × 10–6 mm3/(N·m) at 30 °C to approximately 3.5 × 10–6 mm3/(N·m) at 80 °C. At high temperatures, the cohesive properties of the polymeric matrix were significantly reduced, thus enhancing the polymer abrasive wear [13−15]. Figure 4 presents typical axonometric projections from virgin and as-worn counter body surfaces. Grooves aligned in the sliding direction on the metallic surfaces were formed during the tribological tests. The resulting average root mean square roughness (Rq) values measured on the virgin and worn counter body surfaces are summarized in Fig. 5. Sliding tests increased the counter body surface roughness by approximately 600%. It is clear that the tribological tests drastically changed the topography of the counter bodies. However, the resulting roughness after the tribological tests seemed to be independent of evaluated temperatures and atmospheres. Moreover, profile analyses on wear tracks were performed to evaluate the nature of the groves dis- played in Fig. 4. As exemplified in Fig. 6, peaks and valleys were defined from the mean height of the virgin region, and their areas were calculated. Six profiles were evaluated for each tested condition. From the results, no statistically relevant difference was observed between the total area of the peaks and valleys. In other words, representative volumetric changes did not occur on the metallic surfaces. Therefore, it is possible to attribute groove formation to a microploughing abrasive mechanism [16]. Because successive plowing leads to microfatigue wear mechanisms [16], one can consider these grooves to have been mainly produced in the earlier stages of tribological contact, when the nominal contact pressure was close to 210 MPa, which is about the yield stress of AISI 304 stainless steel (215 MPa). However, previous work [17] has revealed that even πlR 1 (1v2) (1v2) 12 (2) EE1 E2 where F is the applied load, and l and R are the cylinder length and radius, respectively. E and v represent the Young’s Modulus and the Poisson coefficient, whereas the indices 1 and 2 represent the polymeric cylinder and the metallic counter body, respectively. The nominal pressure is given by the applied load divided by the apparent contact area (worn area in Fig. 2(b)). The resulting average wear rates experienced by the polymeric composites are summarized in Fig. 3. Atmospheric air and tetrafluoroethane showed no representative effect on the polymer wear rates. Cannaday and Polycarpou [3] reported that PEEK and PEEK composites showed a slight wear rate reduction when tested in a tetrafluoroethane atmosphere. Howe- ver, the temperature drove the increase in wear rates Wear rate of PEEK cylinders during sliding tests against AISI 304 stainless steel discs. Fig. 3PDF Image | Effect of temperature and atmosphere on the tribological behavior of a polyether ether ketone composite

PDF Search Title:

Effect of temperature and atmosphere on the tribological behavior of a polyether ether ketone compositeOriginal File Name Searched:

tribological-Effect-Temperature-Atmosphe.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |