PDF Publication Title:

Text from PDF Page: 011

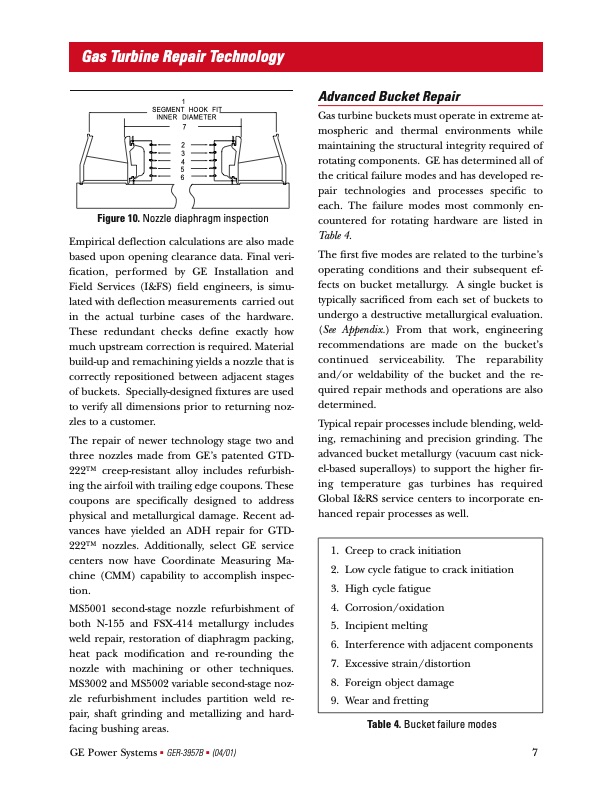

Gas Turbine Repair Technology 1 SEGMENT HOOK FIT INNER DIAMETER 7 2 3 4 5 6 Figure 10. Nozzle diaphragm inspection Empirical deflection calculations are also made based upon opening clearance data. Final veri- fication, performed by GE Installation and Field Services (I&FS) field engineers, is simu- lated with deflection measurements carried out in the actual turbine cases of the hardware. These redundant checks define exactly how much upstream correction is required. Material build-up and remachining yields a nozzle that is correctly repositioned between adjacent stages of buckets. Specially-designed fixtures are used to verify all dimensions prior to returning noz- zles to a customer. The repair of newer technology stage two and three nozzles made from GE’s patented GTD- 222TM creep-resistant alloy includes refurbish- ing the airfoil with trailing edge coupons. These coupons are specifically designed to address physical and metallurgical damage. Recent ad- vances have yielded an ADH repair for GTD- 222TM nozzles. Additionally, select GE service centers now have Coordinate Measuring Ma- chine (CMM) capability to accomplish inspec- tion. MS5001 second-stage nozzle refurbishment of both N-155 and FSX-414 metallurgy includes weld repair, restoration of diaphragm packing, heat pack modification and re-rounding the nozzle with machining or other techniques. MS3002 and MS5002 variable second-stage noz- zle refurbishment includes partition weld re- pair, shaft grinding and metallizing and hard- facing bushing areas. Advanced Bucket Repair Gas turbine buckets must operate in extreme at- mospheric and thermal environments while maintaining the structural integrity required of rotating components. GE has determined all of the critical failure modes and has developed re- pair technologies and processes specific to each. The failure modes most commonly en- countered for rotating hardware are listed in Table 4. The first five modes are related to the turbine’s operating conditions and their subsequent ef- fects on bucket metallurgy. A single bucket is typically sacrificed from each set of buckets to undergo a destructive metallurgical evaluation. (See Appendix.) From that work, engineering recommendations are made on the bucket’s continued serviceability. The reparability and/or weldability of the bucket and the re- quired repair methods and operations are also determined. Typical repair processes include blending, weld- ing, remachining and precision grinding. The advanced bucket metallurgy (vacuum cast nick- el-based superalloys) to support the higher fir- ing temperature gas turbines has required Global I&RS service centers to incorporate en- hanced repair processes as well. 1. Creep to crack initiation 2. Low cycle fatigue to crack initiation 3. High cycle fatigue 4. Corrosion/oxidation 5. Incipient melting 6. Interference with adjacent components 7. Excessive strain/distortion 8. Foreign object damage 9. Wear and fretting GE Power Systems ■ GER-3957B ■ (04/01) 7 Table 4. Bucket failure modesPDF Image | Gas Turbine Repair Technology GE

PDF Search Title:

Gas Turbine Repair Technology GEOriginal File Name Searched:

ger-3957b-gas-turbine-repair-technology.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |