PDF Publication Title:

Text from PDF Page: 012

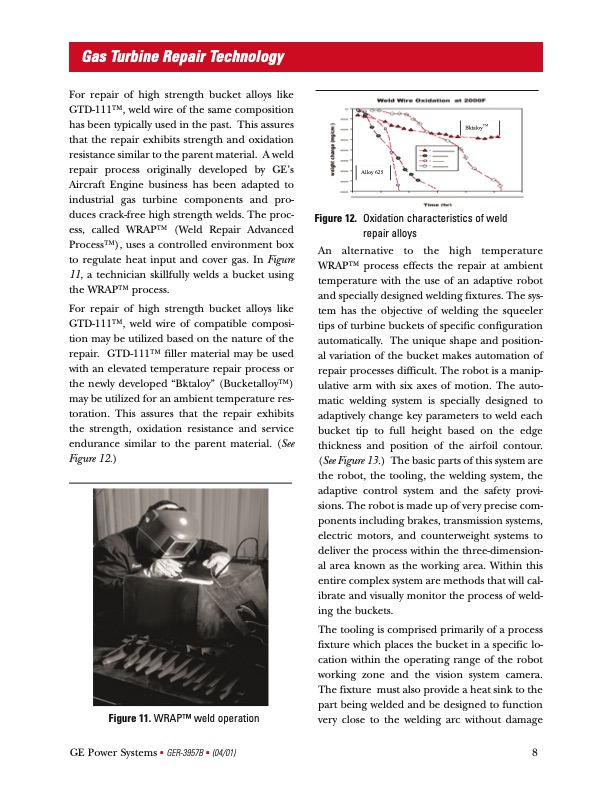

Gas Turbine Repair Technology For repair of high strength bucket alloys like GTD-111TM, weld wire of the same composition has been typically used in the past. This assures that the repair exhibits strength and oxidation resistance similar to the parent material. A weld repair process originally developed by GE’s Aircraft Engine business has been adapted to industrial gas turbine components and pro- duces crack-free high strength welds. The proc- ess, called WRAPTM (Weld Repair Advanced ProcessTM), uses a controlled environment box to regulate heat input and cover gas. In Figure 11, a technician skillfully welds a bucket using the WRAPTM process. For repair of high strength bucket alloys like GTD-111TM, weld wire of compatible composi- tion may be utilized based on the nature of the repair. GTD-111TM filler material may be used with an elevated temperature repair process or the newly developed “Bktaloy” (BucketalloyTM) may be utilized for an ambient temperature res- toration. This assures that the repair exhibits the strength, oxidation resistance and service endurance similar to the parent material. (See Figure 12.) Figure 11. WRAPTM weld operation An alternative to the high temperature WRAPTM process effects the repair at ambient temperature with the use of an adaptive robot and specially designed welding fixtures. The sys- tem has the objective of welding the squeeler tips of turbine buckets of specific configuration automatically. The unique shape and position- al variation of the bucket makes automation of repair processes difficult. The robot is a manip- ulative arm with six axes of motion. The auto- matic welding system is specially designed to adaptively change key parameters to weld each bucket tip to full height based on the edge thickness and position of the airfoil contour. (See Figure 13.) The basic parts of this system are the robot, the tooling, the welding system, the adaptive control system and the safety provi- sions. The robot is made up of very precise com- ponents including brakes, transmission systems, electric motors, and counterweight systems to deliver the process within the three-dimension- al area known as the working area. Within this entire complex system are methods that will cal- ibrate and visually monitor the process of weld- ing the buckets. The tooling is comprised primarily of a process fixture which places the bucket in a specific lo- cation within the operating range of the robot working zone and the vision system camera. The fixture must also provide a heat sink to the part being welded and be designed to function very close to the welding arc without damage BktaloyTM Alloy 625 Figure12. Oxidationcharacteristicsofweld repair alloys GE Power Systems ■ GER-3957B ■ (04/01) 8PDF Image | Gas Turbine Repair Technology GE

PDF Search Title:

Gas Turbine Repair Technology GEOriginal File Name Searched:

ger-3957b-gas-turbine-repair-technology.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |