PDF Publication Title:

Text from PDF Page: 016

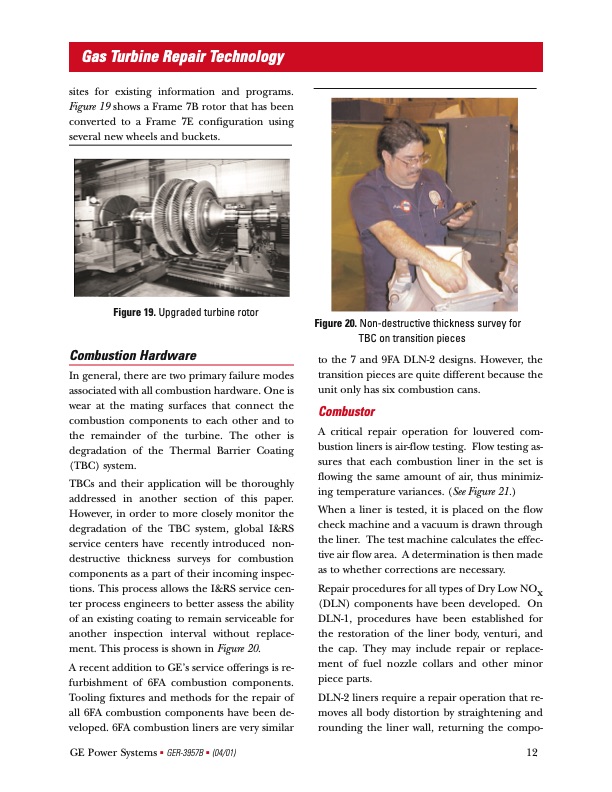

Gas Turbine Repair Technology sites for existing information and programs. Figure 19 shows a Frame 7B rotor that has been converted to a Frame 7E configuration using several new wheels and buckets. Figure 19. Upgraded turbine rotor Combustion Hardware In general, there are two primary failure modes associated with all combustion hardware. One is wear at the mating surfaces that connect the combustion components to each other and to the remainder of the turbine. The other is degradation of the Thermal Barrier Coating (TBC) system. TBCs and their application will be thoroughly addressed in another section of this paper. However, in order to more closely monitor the degradation of the TBC system, global I&RS service centers have recently introduced non- destructive thickness surveys for combustion components as a part of their incoming inspec- tions. This process allows the I&RS service cen- ter process engineers to better assess the ability of an existing coating to remain serviceable for another inspection interval without replace- ment. This process is shown in Figure 20. A recent addition to GE’s service offerings is re- furbishment of 6FA combustion components. Tooling fixtures and methods for the repair of all 6FA combustion components have been de- veloped. 6FA combustion liners are very similar to the 7 and 9FA DLN-2 designs. However, the transition pieces are quite different because the unit only has six combustion cans. Combustor A critical repair operation for louvered com- bustion liners is air-flow testing. Flow testing as- sures that each combustion liner in the set is flowing the same amount of air, thus minimiz- ing temperature variances. (See Figure 21.) When a liner is tested, it is placed on the flow check machine and a vacuum is drawn through the liner. The test machine calculates the effec- tive air flow area. A determination is then made as to whether corrections are necessary. Repair procedures for all types of Dry Low NOx (DLN) components have been developed. On DLN-1, procedures have been established for the restoration of the liner body, venturi, and the cap. They may include repair or replace- ment of fuel nozzle collars and other minor piece parts. DLN-2 liners require a repair operation that re- moves all body distortion by straightening and rounding the liner wall, returning the compo- GE Power Systems ■ GER-3957B ■ (04/01) 12 Figure 20. Non-destructive thickness survey for TBC on transition piecesPDF Image | Gas Turbine Repair Technology GE

PDF Search Title:

Gas Turbine Repair Technology GEOriginal File Name Searched:

ger-3957b-gas-turbine-repair-technology.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |