PDF Publication Title:

Text from PDF Page: 017

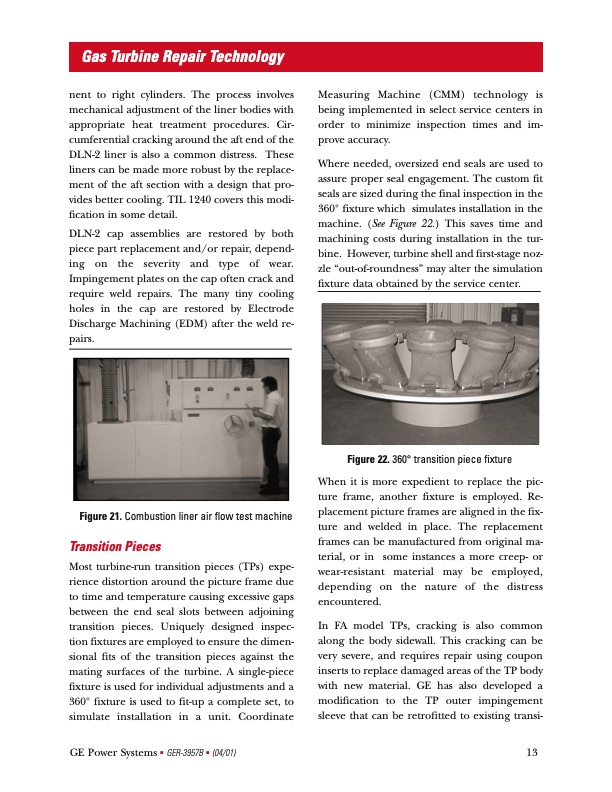

Gas Turbine Repair Technology nent to right cylinders. The process involves mechanical adjustment of the liner bodies with appropriate heat treatment procedures. Cir- cumferential cracking around the aft end of the DLN-2 liner is also a common distress. These liners can be made more robust by the replace- ment of the aft section with a design that pro- vides better cooling. TIL 1240 covers this modi- fication in some detail. DLN-2 cap assemblies are restored by both piece part replacement and/or repair, depend- ing on the severity and type of wear. Impingement plates on the cap often crack and require weld repairs. The many tiny cooling holes in the cap are restored by Electrode Discharge Machining (EDM) after the weld re- pairs. Figure 21. Combustion liner air flow test machine Transition Pieces Most turbine-run transition pieces (TPs) expe- rience distortion around the picture frame due to time and temperature causing excessive gaps between the end seal slots between adjoining transition pieces. Uniquely designed inspec- tion fixtures are employed to ensure the dimen- sional fits of the transition pieces against the mating surfaces of the turbine. A single-piece fixture is used for individual adjustments and a 360° fixture is used to fit-up a complete set, to simulate installation in a unit. Coordinate Measuring Machine (CMM) technology is being implemented in select service centers in order to minimize inspection times and im- prove accuracy. Where needed, oversized end seals are used to assure proper seal engagement. The custom fit seals are sized during the final inspection in the 360° fixture which simulates installation in the machine. (See Figure 22.) This saves time and machining costs during installation in the tur- bine. However, turbine shell and first-stage noz- zle “out-of-roundness” may alter the simulation fixture data obtained by the service center. Figure 22. 360° transition piece fixture When it is more expedient to replace the pic- ture frame, another fixture is employed. Re- placement picture frames are aligned in the fix- ture and welded in place. The replacement frames can be manufactured from original ma- terial, or in some instances a more creep- or wear-resistant material may be employed, depending on the nature of the distress encountered. In FA model TPs, cracking is also common along the body sidewall. This cracking can be very severe, and requires repair using coupon inserts to replace damaged areas of the TP body with new material. GE has also developed a modification to the TP outer impingement sleeve that can be retrofitted to existing transi- GE Power Systems ■ GER-3957B ■ (04/01) 13PDF Image | Gas Turbine Repair Technology GE

PDF Search Title:

Gas Turbine Repair Technology GEOriginal File Name Searched:

ger-3957b-gas-turbine-repair-technology.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |