PDF Publication Title:

Text from PDF Page: 018

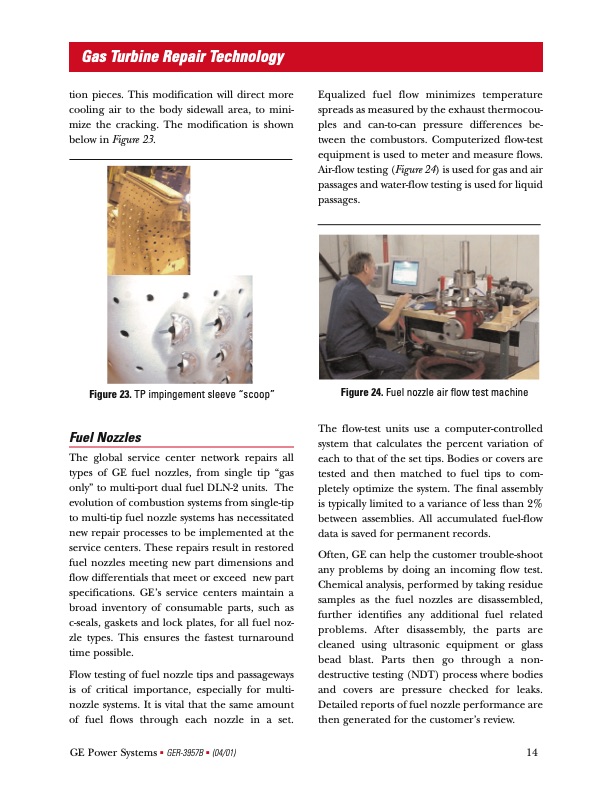

Gas Turbine Repair Technology tion pieces. This modification will direct more cooling air to the body sidewall area, to mini- mize the cracking. The modification is shown below in Figure 23. Fuel Nozzles The global service center network repairs all types of GE fuel nozzles, from single tip “gas only” to multi-port dual fuel DLN-2 units. The evolution of combustion systems from single-tip to multi-tip fuel nozzle systems has necessitated new repair processes to be implemented at the service centers. These repairs result in restored fuel nozzles meeting new part dimensions and flow differentials that meet or exceed new part specifications. GE’s service centers maintain a broad inventory of consumable parts, such as c-seals, gaskets and lock plates, for all fuel noz- zle types. This ensures the fastest turnaround time possible. Flow testing of fuel nozzle tips and passageways is of critical importance, especially for multi- nozzle systems. It is vital that the same amount of fuel flows through each nozzle in a set. Equalized fuel flow minimizes temperature spreads as measured by the exhaust thermocou- ples and can-to-can pressure differences be- tween the combustors. Computerized flow-test equipment is used to meter and measure flows. Air-flow testing (Figure 24) is used for gas and air passages and water-flow testing is used for liquid passages. Figure 24. Fuel nozzle air flow test machine The flow-test units use a computer-controlled system that calculates the percent variation of each to that of the set tips. Bodies or covers are tested and then matched to fuel tips to com- pletely optimize the system. The final assembly is typically limited to a variance of less than 2% between assemblies. All accumulated fuel-flow data is saved for permanent records. Figure 23. TP impingement sleeve “scoop” Often, GE can help the customer trouble-shoot any problems by doing an incoming flow test. Chemical analysis, performed by taking residue samples as the fuel nozzles are disassembled, further identifies any additional fuel related problems. After disassembly, the parts are cleaned using ultrasonic equipment or glass bead blast. Parts then go through a non- destructive testing (NDT) process where bodies and covers are pressure checked for leaks. Detailed reports of fuel nozzle performance are then generated for the customer’s review. GE Power Systems ■ GER-3957B ■ (04/01) 14PDF Image | Gas Turbine Repair Technology GE

PDF Search Title:

Gas Turbine Repair Technology GEOriginal File Name Searched:

ger-3957b-gas-turbine-repair-technology.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |