PDF Publication Title:

Text from PDF Page: 002

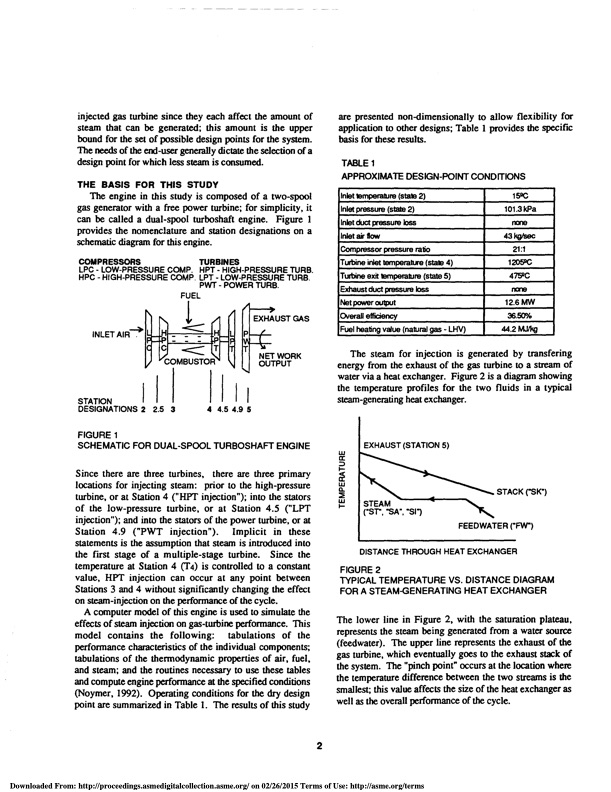

injected gas turbine since they each affect the amount of steam that can be generated; this amount is the upper bound for the set of possible design points for the system. The needs of the end-user generally dictate the selection of a design point for which less steam is consumed. THE BASIS FOR THIS STUDY The engine in this study is composed of a two-spool gas generator with a free power turbine; for simplicity, it can be called a dual-spool turboshaft engine. Figure 1 provides the nomenclature and station designations on a schematic diagram for this engine. COMPRESSORS TURBINES are presented non-dimensionally to allow flexibility for application to other designs; Table 1 provides the specific basis for these results. TABLE 1 APPROXIMATE DESIGN-POINT CONDITIONS LPC - LOW-PRESSURE COMP. HPT - HIGH-PRESSURE TURB. HPC - HIGH-PRESSURE COMP. LPT - LOW-PRESSURE TURB. Compressor pressure ratio Turbine inlet temperature (state 4) Turbine exit temperature (state 5) Exhaust duct pressure loss Net power output Overall efficiency Fuel heating value (natural gas - INLET AIR PWT - POWER TURB. FUEL I I EXHAUST GAS H P LHV) *--. ` T BUSTOR NET WORK OUTPUT The steam for injection is generated by transfering energy from the exhaust of the gas turbine to a stream of water via a heat exchanger. Figure 2 is a diagram showing the temperature profiles for the two fluids in a typical steam-generating heat exchanger. I III STATION DESIGNATIONS 2 2.5 3 4 4.5 4.9 5 FIGURE 1 SCHEMATIC FOR DUAL-SPOOL TURBOSHAFT ENGINE Since there are three turbines, there are three primary locations for injecting steam: prior to the high-pressure turbine, or at Station 4 ("HPT injection"); into the stators of the low-pressure turbine, or at Station 4.5 ("LPT injection"); and into the stators of the power turbine, or at Station 4.9 ("PWT injection"). Implicit in these statements is the assumption that steam is introduced into the first stage of a multiple-stage turbine. Since the temperature at Station 4 (T4) is controlled to a constant value, HPT injection can occur at any point between Stations 3 and 4 without significantly changing the effect on steam-injection on the performance of the cycle. A computer model of this engine is used to simulate the effects of steam injection on gas-turbine performance. This model contains the following: tabulations of the performance characteristics of the individual components; tabulations of the thermodynamic properties of air, fuel, and steam; and the routines necessary to use these tables and compute engine performance at the specified conditions (Noymer, 1992). Operating conditions for the dry design point are summarized in Table 1. The results of this study w Q EXHAUST (STATION 5) 2 Inlet temperature (state 2) Inlet pressure (state 2) Inlet duct pressure loss Inlet air low 1520 101.3 kPa none 43 kg/sec 21:1 120550 4752C none 12.6 MW 36.50% 44.2 M,t/kg W Sr. SA•, - 1iI STACK (•SK•) FEED WATER ("FW ) DISTANCE THROUGH HEAT EXCHANGER FIGURE 2 TYPICAL TEMPERATURE VS. DISTANCE DIAGRAM FOR A STEAM-GENERATING HEAT EXCHANGER The lower line in Figure 2, with the saturation plateau, represents the steam being generated from a water source (feedwater). The upper line represents the exhaust of the gas turbine, which eventually goes to the exhaust stack of the system. The "pinch point" occurs at the location where the temperature difference between the two streams is the smallest; this value affects the size of the heat exchanger as well as the overall performance of the cycle. L>TEA SI') Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 02/26/2015 Terms of Use: http://asme.org/termsPDF Image | Thermodynamic Design Considerations Steam injected gas turbines

PDF Search Title:

Thermodynamic Design Considerations Steam injected gas turbinesOriginal File Name Searched:

steam-injected-gas-turbine.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |