PDF Publication Title:

Text from PDF Page: 006

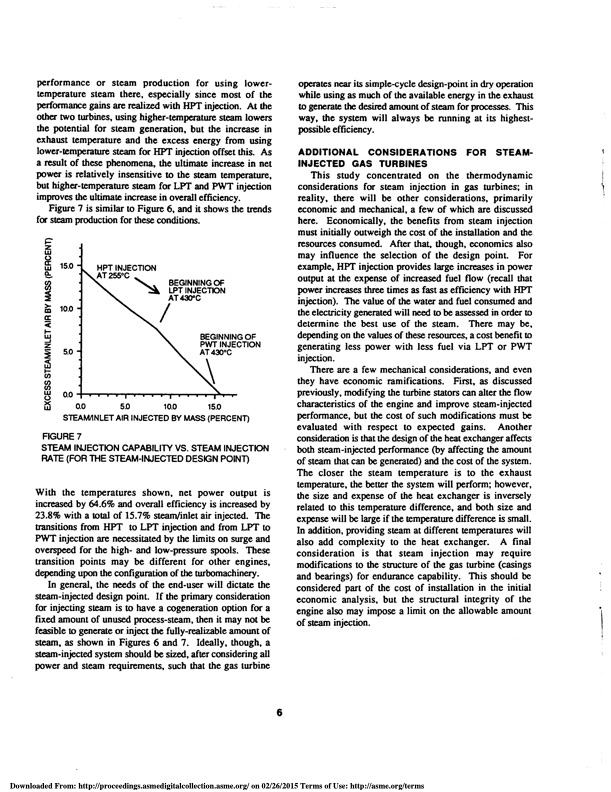

performance or steam production for using lower- temperature steam there, especially since most of the performance gains are realized with HPT injection. At the other two turbines, using higher-temperature steam lowers the potential for steam generation, but the increase in exhaust temperature and the excess energy from using lower-temperature steam for HPT injection offset this. As a result of these phenomena, the ultimate increase in net power is relatively insensitive to the steam temperature, but higher-temperature steam for LPT and PWT injection improves the ultimate increase in overall efficiency. Figure 7 is similar to Figure 6, and it shows the trends for steam production for these conditions. operates near its simple-cycle design-point in dry operation while using as much of the available energy in the exhaust to generate the desired amount of steam for processes. This way, the system will always be running at its highest- possible efficiency. ADDITIONAL CONSIDERATIONS FOR STEAM - INJECTED GAS TURBINES This study concentrated on the thermodynamic considerations for steam injection in gas turbines; in reality, there will be other considerations, primarily economic and mechanical, a few of which are discussed here. Economically, the benefits from steam injection must initially outweigh the cost of the installation and the resources consumed. After that, though, economics also may influence the selection of the design point. For example, HPT injection provides large increases in power output at the expense of increased fuel flow (recall that power increases three times as fast as efficiency with HPT injection). The value of the water and fuel consumed and the electricity generated will need to be assessed in order to determine the best use of the steam. There may be, depending on the values of these resources, a cost benefit to generating less power with less fuel via LPT or PWT injection. There are a few mechanical considerations, and even they have economic ramifications. First, as discussed previously, modifying the turbine stators can alter the flow characteristics of the engine and improve steam-injected performance, but the cost of such modifications must be evaluated with respect to expected gains. Another consideration is that the design of the heat exchanger affects both steam-injected performance (by affecting the amount of steam that can be generated) and the cost of the system. The closer the steam temperature is to the exhaust temperature, the better the system will perform; however, the size and expense of the heat exchanger is inversely related to this temperature difference, and both size and expense will be large if the temperature difference is small. In addition, providing steam at different temperatures will also add complexity to the heat exchanger. A final consideration is that steam injection may require modifications to the structure of the gas turbine (casings and bearings) for endurance capability. This should be considered part of the cost of installation in the initial economic analysis, but the structural integrity of the engine also may impose a limit on the allowable amount of steam injection. 6 t= z wUw 150 10.0 5.0 HPT INJECTION AT 255°C a z BEGINNING OF T CTION AT 430°C BEGINNING OF PWT INJECTION AT 430°C co V 0.0 0.0 STEAM/INLET AIR INJECTED BY MASS (PERCENT) FIGURE 7 STEAM INJECTION CAPABILITY VS. STEAM INJECTION RATE (FOR THE STEAM-INJECTED DESIGN POINT) With the temperatures shown, net power output is increased by 64.6% and overall efficiency is increased by 23.8% with a total of 15.7% steam/inlet air injected. The transitions from HPT to LPT injection and from LPT to PWT injection are necessitated by the limits on surge and overspeed for the high- and low-pressure spools. These transition points may be different for other engines, depending upon the configuration of the turbomachinery. In general, the needs of the end-user will dictate the steam-injected design point. If the primary consideration for injecting steam is to have a cogeneration option for a fixed amount of unused process-steam, then it may not be feasible to generate or inject the fully-realizable amount of steam, as shown in Figures 6 and 7. Ideally, though, a steam-injected system should be sized, after considering all power and steam requirements, such that the gas turbine 5D 10.0 15.0 Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 02/26/2015 Terms of Use: http://asme.org/termsPDF Image | Thermodynamic Design Considerations Steam injected gas turbines

PDF Search Title:

Thermodynamic Design Considerations Steam injected gas turbinesOriginal File Name Searched:

steam-injected-gas-turbine.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |