PDF Publication Title:

Text from PDF Page: 010

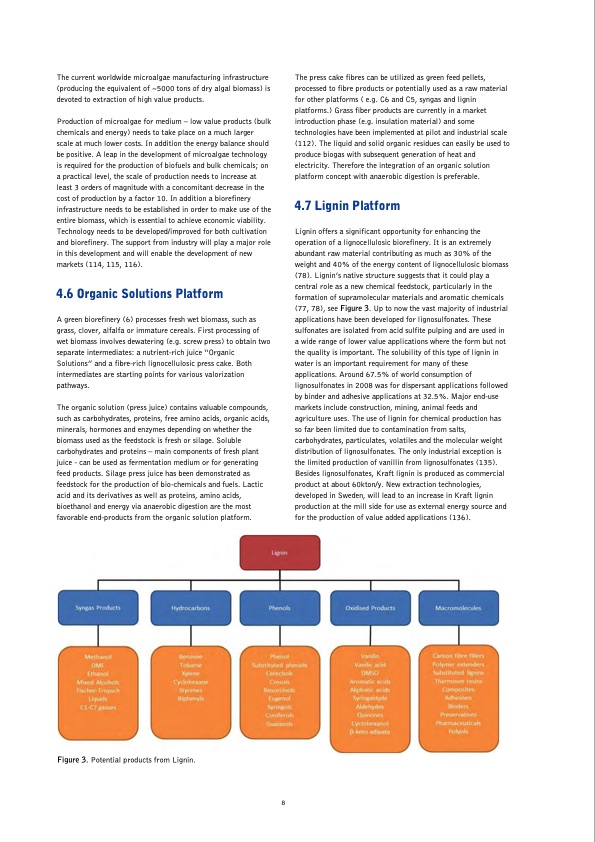

The current worldwide microalgae manufacturing infrastructure (producing the equivalent of ~5000 tons of dry algal biomass) is devoted to extraction of high value products. Production of microalgae for medium – low value products (bulk chemicals and energy) needs to take place on a much larger scale at much lower costs. In addition the energy balance should be positive. A leap in the development of microalgae technology is required for the production of biofuels and bulk chemicals; on a practical level, the scale of production needs to increase at least 3 orders of magnitude with a concomitant decrease in the cost of production by a factor 10. In addition a biorefinery infrastructure needs to be established in order to make use of the entire biomass, which is essential to achieve economic viability. Technology needs to be developed/improved for both cultivation and biorefinery. The support from industry will play a major role in this development and will enable the development of new markets (114, 115, 116). 4.6 Organic Solutions Platform A green biorefinery (6) processes fresh wet biomass, such as grass, clover, alfalfa or immature cereals. First processing of wet biomass involves dewatering (e.g. screw press) to obtain two separate intermediates: a nutrient-rich juice “Organic Solutions” and a fibre-rich lignocellulosic press cake. Both intermediates are starting points for various valorization pathways. The organic solution (press juice) contains valuable compounds, such as carbohydrates, proteins, free amino acids, organic acids, minerals, hormones and enzymes depending on whether the biomass used as the feedstock is fresh or silage. Soluble carbohydrates and proteins – main components of fresh plant juice - can be used as fermentation medium or for generating feed products. Silage press juice has been demonstrated as feedstock for the production of bio-chemicals and fuels. Lactic acid and its derivatives as well as proteins, amino acids, bioethanol and energy via anaerobic digestion are the most favorable end-products from the organic solution platform. The press cake fibres can be utilized as green feed pellets, processed to fibre products or potentially used as a raw material for other platforms ( e.g. C6 and C5, syngas and lignin platforms.) Grass fiber products are currently in a market introduction phase (e.g. insulation material) and some technologies have been implemented at pilot and industrial scale (112). The liquid and solid organic residues can easily be used to produce biogas with subsequent generation of heat and electricity. Therefore the integration of an organic solution platform concept with anaerobic digestion is preferable. 4.7 Lignin Platform Lignin offers a significant opportunity for enhancing the operation of a lignocellulosic biorefinery. It is an extremely abundant raw material contributing as much as 30% of the weight and 40% of the energy content of lignocellulosic biomass (78). Lignin’s native structure suggests that it could play a central role as a new chemical feedstock, particularly in the formation of supramolecular materials and aromatic chemicals (77, 78), see Figure 3. Up to now the vast majority of industrial applications have been developed for lignosulfonates. These sulfonates are isolated from acid sulfite pulping and are used in a wide range of lower value applications where the form but not the quality is important. The solubility of this type of lignin in water is an important requirement for many of these applications. Around 67.5% of world consumption of lignosulfonates in 2008 was for dispersant applications followed by binder and adhesive applications at 32.5%. Major end-use markets include construction, mining, animal feeds and agriculture uses. The use of lignin for chemical production has so far been limited due to contamination from salts, carbohydrates, particulates, volatiles and the molecular weight distribution of lignosulfonates. The only industrial exception is the limited production of vanillin from lignosulfonates (135). Besides lignosulfonates, Kraft lignin is produced as commercial product at about 60kton/y. New extraction technologies, developed in Sweden, will lead to an increase in Kraft lignin production at the mill side for use as external energy source and for the production of value added applications (136). Figure 3. Potential products from Lignin. 8PDF Image | Bio-based Chemicals Value Added Products from Biorefineries

PDF Search Title:

Bio-based Chemicals Value Added Products from BiorefineriesOriginal File Name Searched:

Task-42-Biobased-Chemicals-value-added-products-from-biorefineries.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |