PDF Publication Title:

Text from PDF Page: 013

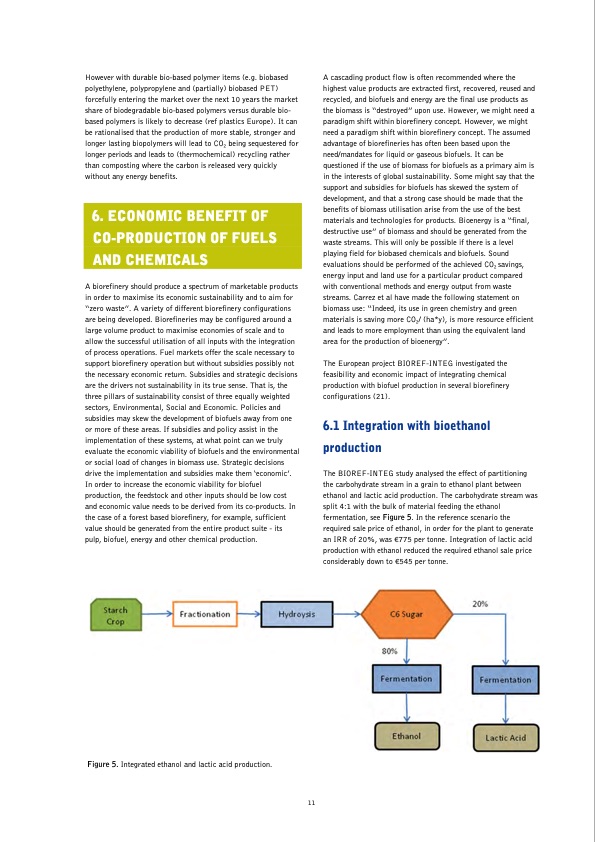

However with durable bio-based polymer items (e.g. biobased polyethylene, polypropylene and (partially) biobased PET) forcefully entering the market over the next 10 years the market share of biodegradable bio-based polymers versus durable bio- based polymers is likely to decrease (ref plastics Europe). It can be rationalised that the production of more stable, stronger and longer lasting biopolymers will lead to CO2 being sequestered for longer periods and leads to (thermochemical) recycling rather than composting where the carbon is released very quickly without any energy benefits. A biorefinery should produce a spectrum of marketable products in order to maximise its economic sustainability and to aim for “zero waste”. A variety of different biorefinery configurations are being developed. Biorefineries may be configured around a large volume product to maximise economies of scale and to allow the successful utilisation of all inputs with the integration of process operations. Fuel markets offer the scale necessary to support biorefinery operation but without subsidies possibly not the necessary economic return. Subsidies and strategic decisions are the drivers not sustainability in its true sense. That is, the three pillars of sustainability consist of three equally weighted sectors, Environmental, Social and Economic. Policies and subsidies may skew the development of biofuels away from one or more of these areas. If subsidies and policy assist in the implementation of these systems, at what point can we truly evaluate the economic viability of biofuels and the environmental or social load of changes in biomass use. Strategic decisions drive the implementation and subsidies make them ‘economic’. In order to increase the economic viability for biofuel production, the feedstock and other inputs should be low cost and economic value needs to be derived from its co-products. In the case of a forest based biorefinery, for example, sufficient value should be generated from the entire product suite - its pulp, biofuel, energy and other chemical production. A cascading product flow is often recommended where the highest value products are extracted first, recovered, reused and recycled, and biofuels and energy are the final use products as the biomass is “destroyed” upon use. However, we might need a paradigm shift within biorefinery concept. However, we might need a paradigm shift within biorefinery concept. The assumed advantage of biorefineries has often been based upon the need/mandates for liquid or gaseous biofuels. It can be questioned if the use of biomass for biofuels as a primary aim is in the interests of global sustainability. Some might say that the support and subsidies for biofuels has skewed the system of development, and that a strong case should be made that the benefits of biomass utilisation arise from the use of the best materials and technologies for products. Bioenergy is a “final, destructive use” of biomass and should be generated from the waste streams. This will only be possible if there is a level playing field for biobased chemicals and biofuels. Sound evaluations should be performed of the achieved CO2 savings, energy input and land use for a particular product compared with conventional methods and energy output from waste streams. Carrez et al have made the following statement on biomass use: “Indeed, its use in green chemistry and green materials is saving more CO2/ (ha*y), is more resource efficient and leads to more employment than using the equivalent land area for the production of bioenergy”. The European project BIOREF-INTEG investigated the feasibility and economic impact of integrating chemical production with biofuel production in several biorefinery configurations (21). 6.1 Integration with bioethanol production The BIOREF-INTEG study analysed the effect of partitioning the carbohydrate stream in a grain to ethanol plant between ethanol and lactic acid production. The carbohydrate stream was split 4:1 with the bulk of material feeding the ethanol fermentation, see Figure 5. In the reference scenario the required sale price of ethanol, in order for the plant to generate an IRR of 20%, was €775 per tonne. Integration of lactic acid production with ethanol reduced the required ethanol sale price considerably down to €545 per tonne. 6. ECONOMIC BENEFIT OF CO-PRODUCTION OF FUELS AND CHEMICALS Figure 5. Integrated ethanol and lactic acid production. 11PDF Image | Bio-based Chemicals Value Added Products from Biorefineries

PDF Search Title:

Bio-based Chemicals Value Added Products from BiorefineriesOriginal File Name Searched:

Task-42-Biobased-Chemicals-value-added-products-from-biorefineries.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |