PDF Publication Title:

Text from PDF Page: 002

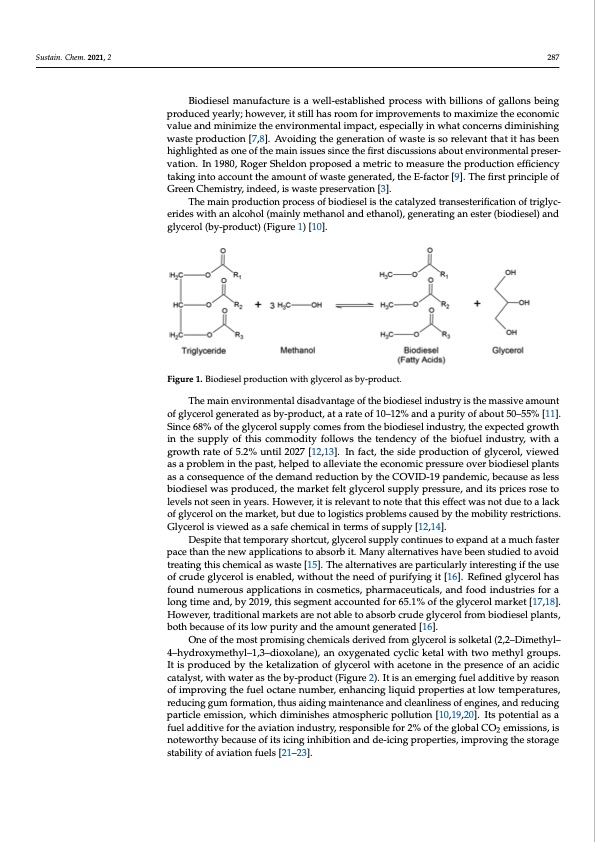

Sustain. Chem. 2021, 2, FOR PEER REVIEW 2 Sustain. Chem. 2021, 2 287 specially where the renewable alternative does not seem to be extensively applied, for instance, in jet and maritime fuel. Biiodiiesellmanufactureiisaawwelell-le-setsatbalbislihsehdedprporcoecsesswsiwthitbhillbiiolnlisonofsgoafllgoanlslobnesinbgepinrgo- pdruocdeudceydeayrelayr;lyh;ohwoewvevr,eirt, isttsiltlilhl hasasroroomffoorriimprovementts to maximize ttheeeccoonnoomicic vaallueaandmininiimiizzeetthheeeennvviriroonnmeennttaallimimppaacctt,,eessppeecciaialllyininwhhaattccoonncceerrnnssddimimininisishhiningg waasstteeprrooduccttiion[[77,8,8]].. Avoiidiingtthegenerrattiionoffwastteiissssorreelleevaantttthaattiitthhaassbbeeenn hiighlilgighhteteddasasonoenoefothfethmeaimnaisinsuiesssusienscesitnhceefitrhstedfiisrcsutsdsiosncussasbionust eanbvoiurotnemnevnirtoalnpmresnetra-l vparteiosenr.vIantio19n8.0In,R1o9g8e0r,RShogeledroSnhpelrdoopnosperdopaomseedtraicmtoetmriceatsoumreetahseurperothdeucptriodnuecftfiiocnienefcfyi- tcaikeincgyitnatkoinagccionutontatchceouanmtotuhnetaomfowuanstteofgwenaesrtaetgeden,ethraetEed-f,atchteorE[-9fa].cTtohre[9fi]r.sTthperifnircsiptlperoinf- Green Chemistry, indeed, is waste preservation [3]. ciple of Green Chemistry, indeed, is waste preservation [3]. The main production process of biodiesel is the catalyzed transesterification of triglyc- The main production process of biodiesel is the catalyzed transesterification of tri- erides with an alcohol (mainly methanol and ethanol), generating an ester (biodiesel) and glycerides with an alcohol (mainly methanol and ethanol), generating an ester (biodiesel) glycerol (by-product) (Figure 1) [10]. and glycerol (by-product) (Figure 1) [10]. Fiigurree11..Biiodiiessellprroduccttiionwiitthggllyycceerroollaassbbyy--pprroodduucct.t. The main environmental disadvantage of the biodiesel industry is the massive amount The main environmental disadvantage of the biodiesel industry is the massive of glycerol generated as by-product, at a rate of 10–12% and a purity of about 50–55% [11]. amount of glycerol generated as by-product, at a rate of 10–12% and a purity of about 50– Since 68% of the glycerol supply comes from the biodiesel industry, the expected growth 55% [11]. Since 68% of the glycerol supply comes from the biodiesel industry, the expected in the supply of this commodity follows the tendency of the biofuel industry, with a growth in the supply of this commodity follows the tendency of the biofuel industry, with growth rate of 5.2% until 2027 [12,13]. In fact, the side production of glycerol, viewed a growth rate of 5.2% until 2027 [12,13]. In fact, the side production of glycerol, viewed as as a problem in the past, helped to alleviate the economic pressure over biodiesel plants a problem in the past, helped to alleviate the economic pressure over biodiesel plants as a as a consequence of the demand reduction by the COVID-19 pandemic, because as less consequence of the demand reduction by the COVID-19 pandemic, because as less bio- biodiesel was produced, the market felt glycerol supply pressure, and its prices rose to diesel was produced, the market felt glycerol supply pressure, and its prices rose to levels levels not seen in years. However, it is relevant to note that this effect was not due to a lack not seen in years. However, it is relevant to note that this effect was not due to a lack of of glycerol on the market, but due to logistics problems caused by the mobility restrictions. glycerol on the market, but due to logistics problems caused by the mobility restrictions. Glycerol is viewed as a safe chemical in terms of supply [12,14]. Glycerol is viewed as a safe chemical in terms of supply [12,14]. Despite that temporary shortcut, glycerol supply continues to expand at a much faster Despite that temporary shortcut, glycerol supply continues to expand at a much pace than the new applications to absorb it. Many alternatives have been studied to avoid faster pace than the new applications to absorb it. Many alternatives have been studied to treating this chemical as waste [15]. The alternatives are particularly interesting if the use avoid treating this chemical as waste [15]. The alternatives are particularly interesting if of crude glycerol is enabled, without the need of purifying it [16]. Refined glycerol has the use of crude glycerol is enabled, without the need of purifying it [16]. Refined glycerol found numerous applications in cosmetics, pharmaceuticals, and food industries for a has found numerous applications in cosmetics, pharmaceuticals, and food industries for long time and, by 2019, this segment accounted for 65.1% of the glycerol market [17,18]. a long time and, by 2019, this segment accounted for 65.1% of the glycerol market [17,18]. However, traditional markets are not able to absorb crude glycerol from biodiesel plants, However, traditional markets are not able to absorb crude glycerol from biodiesel plants, both because of its low purity and the amount generated [16]. both because of its low purity and the amount generated [16]. One of the most promising chemicals derived from glycerol is solketal (2,2–Dimethyl– One of the most promising chemicals derived from glycerol is solketal (2,2–Dime- 4–hydroxymethyl–1,3–dioxolane), an oxygenated cyclic ketal with two methyl groups. thyl–4–hydroxymethyl–1,3–dioxolane), an oxygenated cyclic ketal with two methyl It is produced by the ketalization of glycerol with acetone in the presence of an acidic groups. It is produced by the ketalization of glycerol with acetone in the presence of an catalyst, with water as the by-product (Figure 2). It is an emerging fuel additive by reason acidic catalyst, with water as the by-product (Figure 2). It is an emerging fuel additive by of improving the fuel octane number, enhancing liquid properties at low temperatures, reason of improving the fuel octane number, enhancing liquid properties at low temper- reducing gum formation, thus aiding maintenance and cleanliness of engines, and reducing atures, reducing gum formation, thus aiding maintenance and cleanliness of engines, and particle emission, which diminishes atmospheric pollution [10,19,20]. Its potential as a reducing particle emission, which diminishes atmospheric pollution [10,19,20]. Its poten- fuel additive for the aviation industry, responsible for 2% of the global CO2 emissions, is noteworthy because of its icing inhibition and de-icing properties, improving the storage stability of aviation fuels [21–23].PDF Image | Continuous Valorization of Glycerol into Solketal

PDF Search Title:

Continuous Valorization of Glycerol into SolketalOriginal File Name Searched:

suschem-02-00017.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |