PDF Publication Title:

Text from PDF Page: 026

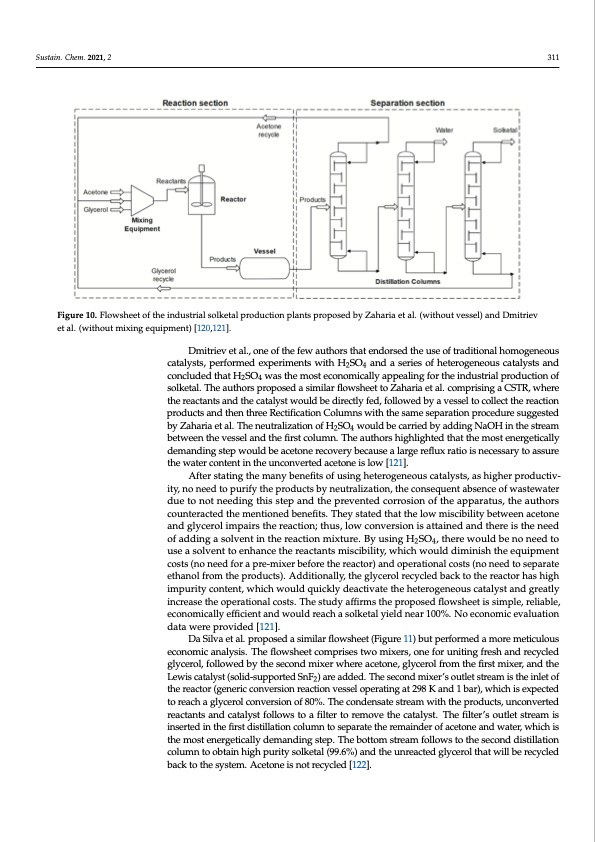

tor’s inlet stream is at 308 K and then the CSTR. The authors proposed that the catalyst could be retained inside the reactor by placing it in a basket or it could be later separated in a cyclone or in a decanting unit. The separation section consists of three distillation columns; in the first, acetone would be separated and recycled, in the second, water would be Sustain. Chem. 2021, 2 311 removed as distillate with 99.9% of purity, and in the third, solketal would be recovered as distillate also with high purity (99.8%) and the unreacted glycerol would be recycled [120]. Figure 10. Flowsheet of the industrial solketal production plants proposed by Zaharia et al. (without vessel) and Dmitriev Figure 10. Flowsheet of the industrial solketal production plants proposed by Zaharia et al. (without vessel) and Dmitriev et al. (without mixing equipment) [120,121]. et al. (without mixing equipment) [120,121]. Dmitriev et al., one of the few authors that endorsed the use of traditional homogeneous In this study, an economic evaluation of the industrial plant is presented; however, catalysts, performed experiments with H2SO4 and a series of heterogeneous catalysts and the authors have not accounted for the reactants and catalyst costs. Moreover, they have concluded that H2SO4 was the most economically appealing for the industrial production of not provided information about glycerol purification costs, which is a necessary step once solketal. The authors proposed a similar flowsheet to Zaharia et al. comprising a CSTR, where Amberlyst–35 is deactivated when salts are present in crude glycerol. Thus, considering a the reactants and the catalyst would be directly fed, followed by a vessel to collect the reaction payback period of five years, the cost to produce 3720 t of solketal/year was estimated at products and then three Rectification Columns with the same separation procedure suggested US$128.50/ton, a much lower value than what was estimated in other studies and which by Zaharia et al. The neutralization of H2SO4 would be carried by adding NaOH in the stream can be considered unrealistic [10,25,120]. between the vessel and the first column. The authors highlighted that the most energetically Dmitriev et al., one of the few authors that endorsed the use of traditional homoge- demanding step would be acetone recovery because a large reflux ratio is necessary to assure neous catalysts, performed experiments with H2SO4 and a series of heterogeneous cata- the water content in the unconverted acetone is low [121]. lysts and concluded that H2SO4 was the most economically appealing for the industrial After stating the many benefits of using heterogeneous catalysts, as higher productiv- production of solketal. The authors proposed a similar flowsheet to Zaharia et al. com- ity, no need to purify the products by neutralization, the consequent absence of wastewater prising a CSTR, where the reactants and the catalyst would be directly fed, followed by a due to not needing this step and the prevented corrosion of the apparatus, the authors vessel to collect the reaction products and then three Rectification Columns with the same counteracted the mentioned benefits. They stated that the low miscibility between acetone separation procedure suggested by Zaharia et al. The neutralization of H2SO4 would be and glycerol impairs the reaction; thus, low conversion is attained and there is the need of adding a solvent in the reaction mixture. By using H2SO4, there would be no need to use a solvent to enhance the reactants miscibility, which would diminish the equipment costs (no need for a pre-mixer before the reactor) and operational costs (no need to separate ethanol from the products). Additionally, the glycerol recycled back to the reactor has high impurity content, which would quickly deactivate the heterogeneous catalyst and greatly increase the operational costs. The study affirms the proposed flowsheet is simple, reliable, economically efficient and would reach a solketal yield near 100%. No economic evaluation data were provided [121]. Da Silva et al. proposed a similar flowsheet (Figure 11) but performed a more meticulous economic analysis. The flowsheet comprises two mixers, one for uniting fresh and recycled glycerol, followed by the second mixer where acetone, glycerol from the first mixer, and the Lewis catalyst (solid-supported SnF2) are added. The second mixer’s outlet stream is the inlet of the reactor (generic conversion reaction vessel operating at 298 K and 1 bar), which is expected to reach a glycerol conversion of 80%. The condensate stream with the products, unconverted reactants and catalyst follows to a filter to remove the catalyst. The filter’s outlet stream is inserted in the first distillation column to separate the remainder of acetone and water, which is the most energetically demanding step. The bottom stream follows to the second distillation column to obtain high purity solketal (99.6%) and the unreacted glycerol that will be recycled back to the system. Acetone is not recycled [122].PDF Image | Continuous Valorization of Glycerol into Solketal

PDF Search Title:

Continuous Valorization of Glycerol into SolketalOriginal File Name Searched:

suschem-02-00017.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |