PDF Publication Title:

Text from PDF Page: 027

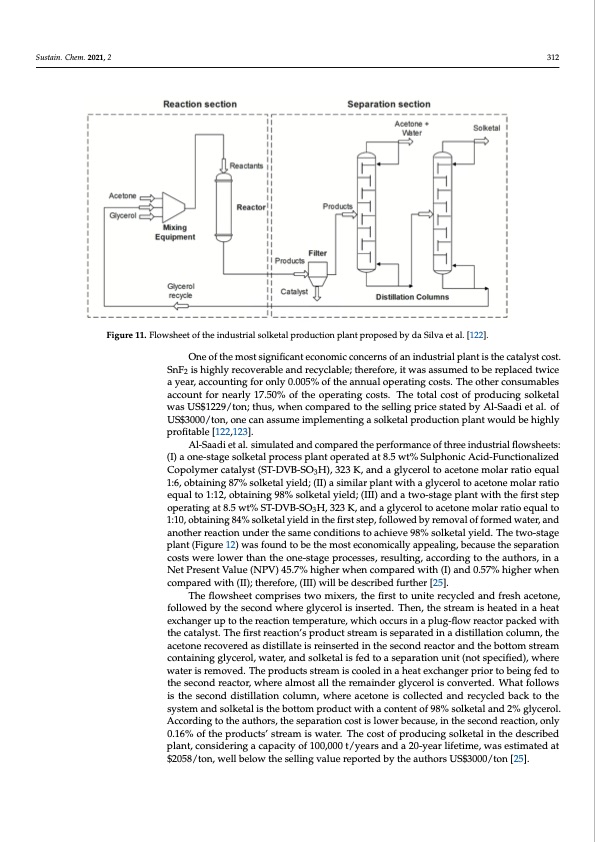

1 bar), which is expected to reach a glycerol conversion of 80%. The condensate stream with the products, unconverted reactants and catalyst follows to a filter to remove the catalyst. The filter’s outlet stream is inserted in the first distillation column to separate the remainder of acetone and water, which is the most energetically demanding step. The bottom stream follows to the second distillation column to obtain high purity solketal Sustain. Chem. 2021, 2 312 (99.6%) and the unreacted glycerol that will be recycled back to the system. Acetone is not recycled [122]. Figure 11. Flowsheet of the industrial solketal production plant proposed by da Silva et al. [122]. Figure 11. Flowsheet of the industrial solketal production plant proposed by da Silva et al. [122]. One of the most significant economic concerns of an industrial plant is the catalyst cost. One of the most significant economic concerns of an industrial plant is the catalyst SnF2 is highly recoverable and recyclable; therefore, it was assumed to be replaced twice cost. SnF2 is highly recoverable and recyclable; therefore, it was assumed to be replaced a year, accounting for only 0.005% of the annual operating costs. The other consumables account for nearly 17.50% of the operating costs. The total cost of producing solketal was US$1229/ton; thus, when compared to the selling price stated by Al-Saadi et al. of US$3000/ton, one can assume implementing a solketal production plant would be highly profitable [122,123]. Al-Saadi et al. simulated and compared the performance of three industrial flowsheets: (I) a one-stage solketal process plant operated at 8.5 wt% Sulphonic Acid-Functionalized Copolymer catalyst (ST-DVB-SO3H), 323 K, and a glycerol to acetone molar ratio equal 1:6, obtaining 87% solketal yield; (II) a similar plant with a glycerol to acetone molar ratio equal to 1:12, obtaining 98% solketal yield; (III) and a two-stage plant with the first step operating at 8.5 wt% ST-DVB-SO3H, 323 K, and a glycerol to acetone molar ratio equal to 1:10, obtaining 84% solketal yield in the first step, followed by removal of formed water, and another reaction under the same conditions to achieve 98% solketal yield. The two-stage plant (Figure 12) was found to be the most economically appealing, because the separation costs were lower than the one-stage processes, resulting, according to the authors, in a Net Present Value (NPV) 45.7% higher when compared with (I) and 0.57% higher when compared with (II); therefore, (III) will be described further [25]. The flowsheet comprises two mixers, the first to unite recycled and fresh acetone, followed by the second where glycerol is inserted. Then, the stream is heated in a heat exchanger up to the reaction temperature, which occurs in a plug-flow reactor packed with the catalyst. The first reaction’s product stream is separated in a distillation column, the acetone recovered as distillate is reinserted in the second reactor and the bottom stream containing glycerol, water, and solketal is fed to a separation unit (not specified), where water is removed. The products stream is cooled in a heat exchanger prior to being fed to the second reactor, where almost all the remainder glycerol is converted. What follows is the second distillation column, where acetone is collected and recycled back to the system and solketal is the bottom product with a content of 98% solketal and 2% glycerol. According to the authors, the separation cost is lower because, in the second reaction, only 0.16% of the products’ stream is water. The cost of producing solketal in the described plant, considering a capacity of 100,000 t/years and a 20-year lifetime, was estimated at $2058/ton, well below the selling value reported by the authors US$3000/ton [25].PDF Image | Continuous Valorization of Glycerol into Solketal

PDF Search Title:

Continuous Valorization of Glycerol into SolketalOriginal File Name Searched:

suschem-02-00017.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |