PDF Publication Title:

Text from PDF Page: 029

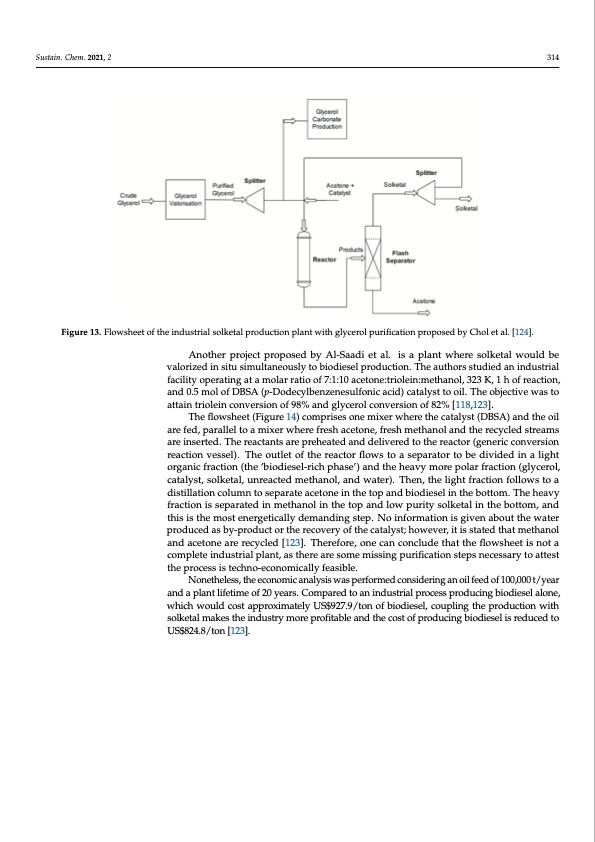

other half of glycerol, i.e., the stream leading to solketal production, was pressurized (12,000 kPa) before being fed into a conversion reactor with acetone and heterogeneous catalyst Amberlyst-15. The reaction was carried at 343 K for 1.5 h. The separation was promoted by a flash separator, where acetone with trace water was vaporized and recov- Sustain. Chem. 2021, 2 ered and the solketal stream was split into pure solketal and a recycle stream that was sent 314 back to the reactor to improve conversion, since glycerol conversion is only 35% but can be enhanced with product recycle, according to the authors [124]. Figure 13. FloFwigsuhree1t 3o.fFtlhoewinshdeuesttroifalthseoliknedtualstprrioaldsuocltkioetnalpplarnotdwucithiognlypclaenrotlwpiuthrifigclyactieornolppruopriofisceadtiboyn Cprho-l et al. [124]. posed by Chol et al. [124]. Another project proposed by Al-Saadi et al. is a plant where solketal would be The ecovnaolmoriczeadnainlysiitsuosfimimupltlaenmeoeunstilnygtothbisodiniedsuesltpriraoldfuloctwiosnh.eTethiesaaultshooprsrosmtuidsiendg,an industrial the cost of trfeaactiilnitgy onpertaotningofactraumdeolgalryrcaetriolowfo7u:1l:d10baecUetSo$n5e0:t4r5io,lweihn:imleettheanreovl,e3n2u3eKc,o1sth of reaction, and 0.5 mol of DBSA (p-Dodecylbenzenesulfonic acid) catalyst to oil. The objective was to would be US $8036, resulting in a profit of almost US $3000/ton of glycerol. The total in- attain triolein conversion of 98% and glycerol conversion of 82% [118,123]. vestment cost was expected to be recovered within three years of operation; considering The flowsheet (Figure 14) comprises one mixer where the catalyst (DBSA) and the oil that the first three years would be dedicated to building the facility, complete recovery is are fed, parallel to a mixer where fresh acetone, fresh methanol and the recycled streams made within six years. According to the authors, these margins are decent for a biodiesel are inserted. The reactants are preheated and delivered to the reactor (generic conversion plant and the increased profit indicate that it would be worth it investing in crude glycerol reaction vessel). The outlet of the reactor flows to a separator to be divided in a light purification and valorization plant [124]. organic fraction (the ‘biodiesel-rich phase’) and the heavy more polar fraction (glycerol, catalyst, solketal, unreacted methanol, and water). Then, the light fraction follows to a distillation column to separate acetone in the top and biodiesel in the bottom. The heavy fraction is separated in methanol in the top and low purity solketal in the bottom, and this is the most energetically demanding step. No information is given about the water produced as by-product or the recovery of the catalyst; however, it is stated that methanol and acetone are recycled [123]. Therefore, one can conclude that the flowsheet is not a complete industrial plant, as there are some missing purification steps necessary to attest the process is techno-economically feasible. Nonetheless, the economic analysis was performed considering an oil feed of 100,000 t/year and a plant lifetime of 20 years. Compared to an industrial process producing biodiesel alone, which would cost approximately US$927.9/ton of biodiesel, coupling the production with solketal makes the industry more profitable and the cost of producing biodiesel is reduced to US$824.8/ton [123].PDF Image | Continuous Valorization of Glycerol into Solketal

PDF Search Title:

Continuous Valorization of Glycerol into SolketalOriginal File Name Searched:

suschem-02-00017.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |