PDF Publication Title:

Text from PDF Page: 054

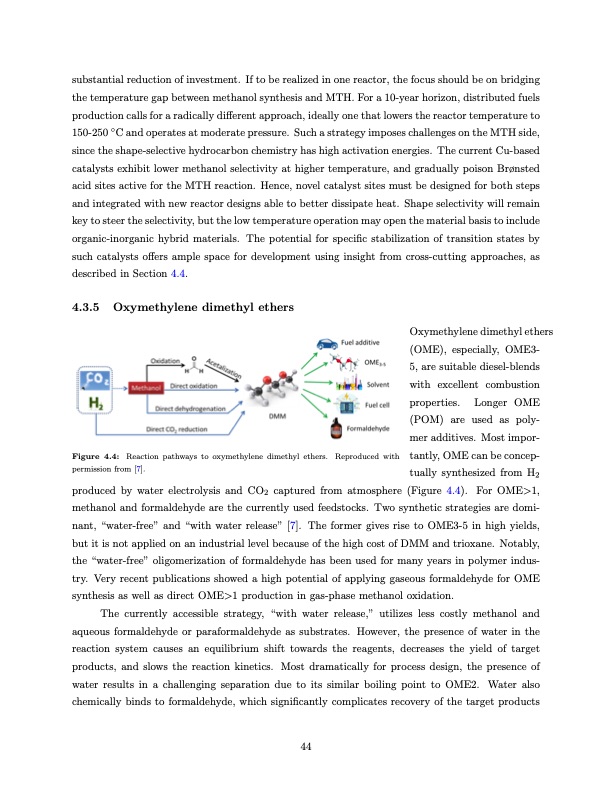

substantial reduction of investment. If to be realized in one reactor, the focus should be on bridging the temperature gap between methanol synthesis and MTH. For a 10-year horizon, distributed fuels production calls for a radically different approach, ideally one that lowers the reactor temperature to 150-250 ◦C and operates at moderate pressure. Such a strategy imposes challenges on the MTH side, since the shape-selective hydrocarbon chemistry has high activation energies. The current Cu-based catalysts exhibit lower methanol selectivity at higher temperature, and gradually poison Brønsted acid sites active for the MTH reaction. Hence, novel catalyst sites must be designed for both steps and integrated with new reactor designs able to better dissipate heat. Shape selectivity will remain key to steer the selectivity, but the low temperature operation may open the material basis to include organic-inorganic hybrid materials. The potential for specific stabilization of transition states by such catalysts offers ample space for development using insight from cross-cutting approaches, as described in Section 4.4. 4.3.5 Oxymethylene dimethyl ethers Figure 4.4: Reaction pathways to oxymethylene dimethyl ethers. Reproduced with permission from [7]. Oxymethylene dimethyl ethers (OME), especially, OME3- 5, are suitable diesel-blends with excellent combustion properties. Longer OME (POM) are used as poly- mer additives. Most impor- tantly, OME can be concep- tually synthesized from H2 produced by water electrolysis and CO2 captured from atmosphere (Figure 4.4). For OME>1, methanol and formaldehyde are the currently used feedstocks. Two synthetic strategies are domi- nant, “water-free” and “with water release” [7]. The former gives rise to OME3-5 in high yields, but it is not applied on an industrial level because of the high cost of DMM and trioxane. Notably, the “water-free” oligomerization of formaldehyde has been used for many years in polymer indus- try. Very recent publications showed a high potential of applying gaseous formaldehyde for OME synthesis as well as direct OME>1 production in gas-phase methanol oxidation. The currently accessible strategy, “with water release,” utilizes less costly methanol and aqueous formaldehyde or paraformaldehyde as substrates. However, the presence of water in the reaction system causes an equilibrium shift towards the reagents, decreases the yield of target products, and slows the reaction kinetics. Most dramatically for process design, the presence of water results in a challenging separation due to its similar boiling point to OME2. Water also chemically binds to formaldehyde, which significantly complicates recovery of the target products 44PDF Image | sustainable production of fuels and chemicals

PDF Search Title:

sustainable production of fuels and chemicalsOriginal File Name Searched:

Energy_X_Research-needs-report.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |