PDF Publication Title:

Text from PDF Page: 060

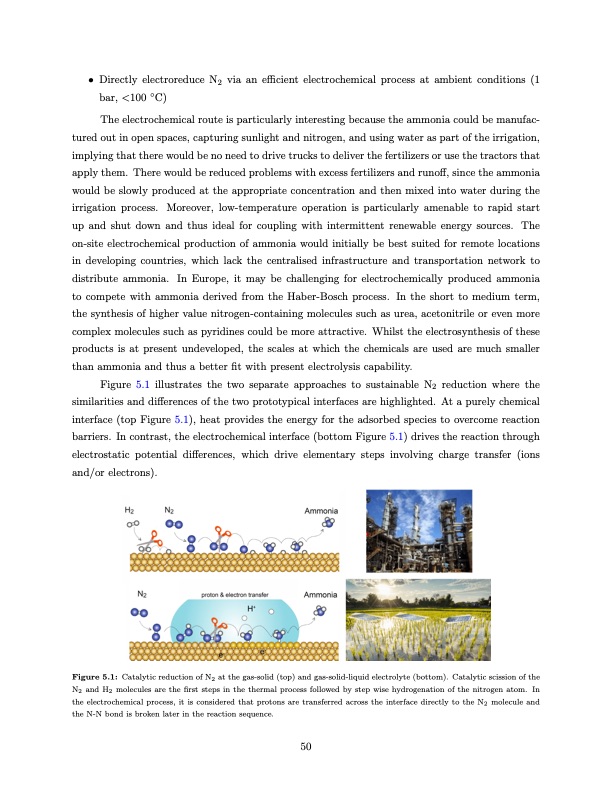

• Directly electroreduce N2 via an efficient electrochemical process at ambient conditions (1 bar, <100 ◦C) The electrochemical route is particularly interesting because the ammonia could be manufac- tured out in open spaces, capturing sunlight and nitrogen, and using water as part of the irrigation, implying that there would be no need to drive trucks to deliver the fertilizers or use the tractors that apply them. There would be reduced problems with excess fertilizers and runoff, since the ammonia would be slowly produced at the appropriate concentration and then mixed into water during the irrigation process. Moreover, low-temperature operation is particularly amenable to rapid start up and shut down and thus ideal for coupling with intermittent renewable energy sources. The on-site electrochemical production of ammonia would initially be best suited for remote locations in developing countries, which lack the centralised infrastructure and transportation network to distribute ammonia. In Europe, it may be challenging for electrochemically produced ammonia to compete with ammonia derived from the Haber-Bosch process. In the short to medium term, the synthesis of higher value nitrogen-containing molecules such as urea, acetonitrile or even more complex molecules such as pyridines could be more attractive. Whilst the electrosynthesis of these products is at present undeveloped, the scales at which the chemicals are used are much smaller than ammonia and thus a better fit with present electrolysis capability. Figure 5.1 illustrates the two separate approaches to sustainable N2 reduction where the similarities and differences of the two prototypical interfaces are highlighted. At a purely chemical interface (top Figure 5.1), heat provides the energy for the adsorbed species to overcome reaction barriers. In contrast, the electrochemical interface (bottom Figure 5.1) drives the reaction through electrostatic potential differences, which drive elementary steps involving charge transfer (ions and/or electrons). Figure 5.1: Catalytic reduction of N2 at the gas-solid (top) and gas-solid-liquid electrolyte (bottom). Catalytic scission of the N2 and H2 molecules are the first steps in the thermal process followed by step wise hydrogenation of the nitrogen atom. In the electrochemical process, it is considered that protons are transferred across the interface directly to the N2 molecule and the N-N bond is broken later in the reaction sequence. 50PDF Image | sustainable production of fuels and chemicals

PDF Search Title:

sustainable production of fuels and chemicalsOriginal File Name Searched:

Energy_X_Research-needs-report.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |