PDF Publication Title:

Text from PDF Page: 086

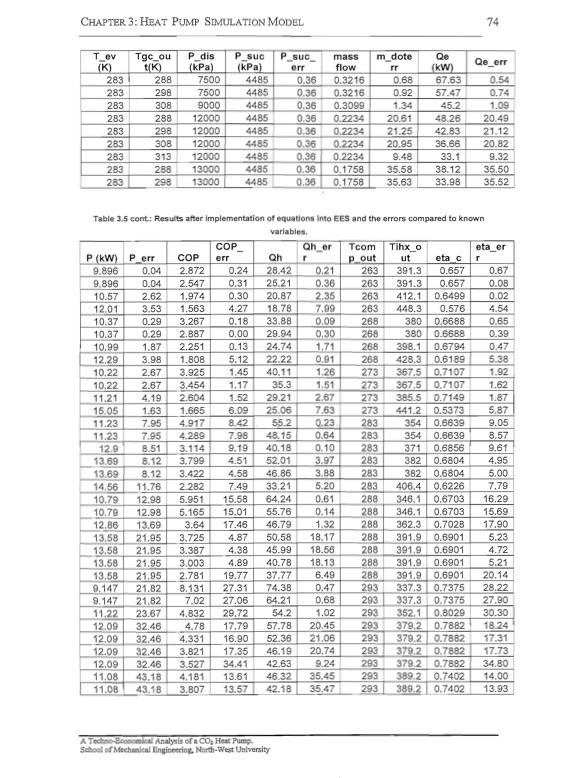

CHAPTER3:HEAT PU1v1P SIMULATIONMODEL 74 T_ev (K) Tgc_ou t(K) P dis (!cPa) 7500 7500 9000 12000 12000 12000 12000 13000 13000 P suc P_suc_ . (kPa) err mass flow 0.3216 0.3216 0.3099 0.2234 0.2234 0.2234 0.2234 0.1758 0.1758 m_dote rr 0.68 0.92 1.34 20.61 21.25 20.95 9.48 35.58 35.63 i Qe (kW) 67.63 57.47 45.2 i 48.26 • 42.83 • 36.66 33.1 38.12 33.98 Qe_err 0.54 0.74 1.09 20.49 21.12 20.82 9.32 • 35.50 35.52 10.57 12.01 10.37 10.37 10.99 ! 12.29 10.22 i 10.22 11.21 2.62 1.974 3.53 1.563 0.29 • 3.267 0.29 ! 2.887 1.87 2.251 3.98 1.808 2.67 3.925 2.67 3.454 4.19 2.604 2.35 7.99 0.657 • 0.6499 0.08 0.02 i 4.54 • I I i 12.98 • 12.98 • 13.69 21.95 • 21.95 21.95 . 21.95 21.82 o~ 283 283 283 283 283 283 283 • 283 • 283 298 4485 0.36 4485 0.36 4485 0.36 4485 0.36 4485 0.36 4485 0.36 4485 0.36 4485 0.36 4485 • 0.36 ! 308 ! 288 ! P(kW) •P err COP 9.896 0.04 2.872 I 9.896 0.04 • 2.547 COP err Qh_er r Tcom pout 263 263 263 Tihx_o ut 391.3 391.3 412.1 I eta_er etac r i 0.657 0.67 15.05 1.63 1.665 0.6794 • 0.6189 0.7107 ! 0.7107 0.7149 i 1.87 0.5373 5.87 11.23 11.23 12.9 • 13.69 13.69 14.56 10.79 10.79 12.86 13.58 7.95 4.917 7.95 4.289 8.51 3.114 8.12 • 3.799 8.12 0.6639 • 0.6639 0.6856 0.6804 0.6804 0.6226 0.6703 0.6703 0.7028 0.6901 0.6901 • I I I 9.05 8.57 • 9.61 I 4.95 I 5.00 i 7.79 16.291 15.69 17.90 i 5.23 i 4.72 5.21 20.14 28.22 27.90 ! 30.30 18.24 17.31 17.73 34.80 14.00 13.93 I 13.58 13.58 13.58 9.147 9.147 21.82 17.46 46.79 1. 4.87 50.58 18.1 4.38 4 18.56 4.89 ! 288 39~901 11.22 12.09 12.09 12.09 12.09 11.08 11.08 23.67 32.46 32.46 • 32.46 32.46 43.18 43.18 40.78 18.13 19.77 37.77 6.49 27.31 74.38 0.47 27.06 • 64.21 0.68 29.72 54.2 1.02 17.79 57¥si 20.45 16.90 52.3 21.06 17.35 46.19 20.74 34.41 42.63 9.24 13.61 46.32 35.45 13.57 42.18 35.47 288 391.9 293 337.3 293 I 337.3 293 I 352.1 293 379.2 293 379.2 293 379.2 293 379.2 293 389.2 293 389.2 • i I 901 0.7375 0.7375 0.8029 0.7882 0.7882 0.7882 0.7882 0.7402 0.7402 11.76 3.422 2.282 5.951 5.165 3.64 3.725 3.387 3.003 2.781 8.131 7.02 4.832 4.78 4.331 3.821 3.527 4.181 3.807 288 • 298 i 298 • 308 I 313 288 Table 3.5 cont.: Results after implementation of equations into EES and the errors compared to known variables. A Techno-Economical Aoalysis of a COl Heat Pump. School of Mechanical Engineering, North-West University • • I • i • • • • I i i 448.3 268 380 2 398.1 268 428.3 273 367.5 273 367.5 273 • 385.5 273 • 441.2 283 354 283 354 283 371 283 382 283 382 283 406.4 288 346.1 288 346.1 288 362.3 288 391.9 288 391.9 0.576 0.6688 0.65 Qh I 28.42 • 0.30 20.87 4.27 18.78 0.18 33.88 0.09 0.00 29.94 0.30 0.13 24.74 1.71 5.12 22.22 n !=i1 1.45 40.11 1.26 1.17 35.3 1.51 1.52 • 29.21 2.67 6.09 25.0 . 3 8.42 5;5.2 3 7.98 48.15 0.64 9.19 40.18 4.51 52.01 3.97 4.58 46.86 3.88 7.49 • 33.21 5.20 15.58 64.24 15.01 55.76 O. 0.21 0.31 25.21 0.36 0.24 • 263 268 ! 380 0.6688 0.39 0.47 5.38 ! 1.92 1.62PDF Image | CO2 HEAT PUMP Analysis

PDF Search Title:

CO2 HEAT PUMP AnalysisOriginal File Name Searched:

co2-heat-pump-techno-analysis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |