PDF Publication Title:

Text from PDF Page: 002

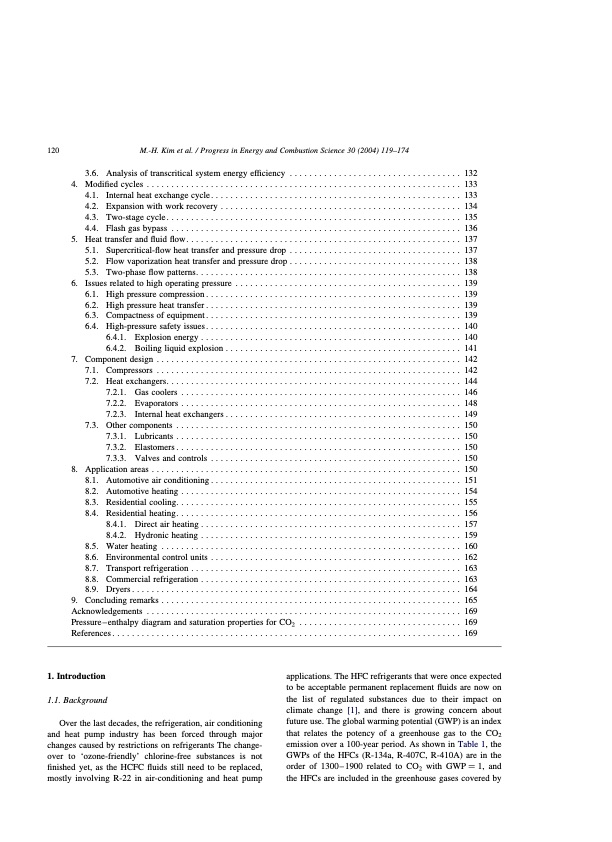

120 4. 5. 6. 7. 8. M.-H. Kim et al. / Progress in Energy and Combustion Science 30 (2004) 119–174 3.6. Analysisoftranscriticalsystemenergyefficiency ................................... 132 Modifiedcycles................................................................ 133 4.1. Internalheatexchangecycle................................................... 133 4.2. Expansionwithworkrecovery................................................. 134 4.3. Two-stagecycle............................................................ 135 4.4. Flashgasbypass ........................................................... 136 Heattransferandfluidflow........................................................ 137 5.1. Supercritical-flowheattransferandpressuredrop ................................... 137 5.2. Flowvaporizationheattransferandpressuredrop................................... 138 5.3. Two-phaseflowpatterns...................................................... 138 Issuesrelatedtohighoperatingpressure .............................................. 139 6.1. Highpressurecompression.................................................... 139 6.2. Highpressureheattransfer.................................................... 139 6.3. Compactnessofequipment.................................................... 139 6.4. High-pressuresafetyissues.................................................... 140 6.4.1. Explosionenergy..................................................... 140 6.4.2. Boilingliquidexplosion................................................ 141 Componentdesign.............................................................. 142 7.1. Compressors..............................................................142 7.2. Heatexchangers............................................................ 144 7.2.1. Gascoolers ......................................................... 146 7.2.2. Evaporators......................................................... 148 7.2.3. Internalheatexchangers................................................ 149 7.3. Othercomponents .......................................................... 150 7.3.1. Lubricants.......................................................... 150 7.3.2. Elastomers.......................................................... 150 7.3.3. Valvesandcontrols ................................................... 150 Applicationareas............................................................... 150 8.1. Automotiveairconditioning................................................... 151 8.2. Automotiveheating......................................................... 154 8.3. Residentialcooling.......................................................... 155 8.4. Residentialheating.......................................................... 156 8.4.1. Directairheating..................................................... 157 8.4.2. Hydronicheating..................................................... 159 8.5. Waterheating ............................................................. 160 8.6. Environmentalcontrolunits................................................... 162 8.7. Transportrefrigeration....................................................... 163 8.8. Commercialrefrigeration..................................................... 163 8.9. Dryers................................................................... 164 Concludingremarks............................................................. 165 9. Acknowledgements ................................................................ 169 Pressure–enthalpydiagramandsaturationpropertiesforCO2 ................................. 169 References....................................................................... 169 1. Introduction 1.1. Background Over the last decades, the refrigeration, air conditioning and heat pump industry has been forced through major changes caused by restrictions on refrigerants The change- over to ‘ozone-friendly’ chlorine-free substances is not finished yet, as the HCFC fluids still need to be replaced, mostly involving R-22 in air-conditioning and heat pump applications. The HFC refrigerants that were once expected to be acceptable permanent replacement fluids are now on the list of regulated substances due to their impact on climate change [1], and there is growing concern about future use. The global warming potential (GWP) is an index that relates the potency of a greenhouse gas to the CO2 emission over a 100-year period. As shown in Table 1, the GWPs of the HFCs (R-134a, R-407C, R-410A) are in the order of 1300 – 1900 related to CO2 with GWP 1⁄4 1; and the HFCs are included in the greenhouse gases covered byPDF Image | CO2 Vapor Compression Systems

PDF Search Title:

CO2 Vapor Compression SystemsOriginal File Name Searched:

co2-vapor-compression-systems.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |