PDF Publication Title:

Text from PDF Page: 003

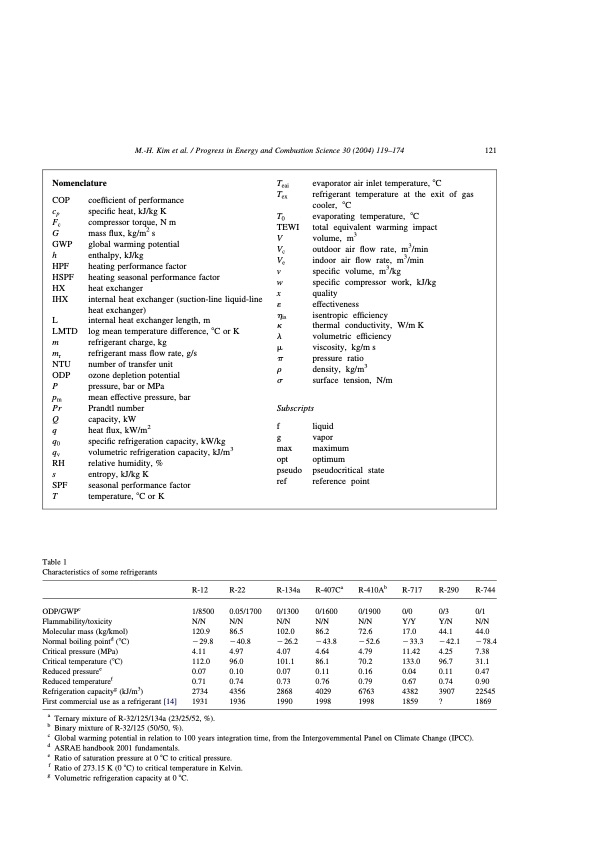

Table 1 Characteristics of some refrigerants ODP/GWPc Flammability/toxicity Molecular mass (kg/kmol) Normal boiling pointd (8C) Critical pressure (MPa) Critical temperature (8C) Reduced pressuree Reduced temperaturef Refrigeration capacityg (kJ/m3) First commercial use as a refrigerant [14] R-12 1/8500 N/N 120.9 2 29.8 4.11 112.0 0.07 0.71 2734 1931 R-22 0.05/1700 N/N 86.5 2 40.8 4.97 96.0 0.10 0.74 4356 1936 R-134a 0/1300 N/N 102.0 2 26.2 4.07 101.1 0.07 0.73 2868 1990 R-407Ca 0/1600 N/N 86.2 2 43.8 4.64 86.1 0.11 0.76 4029 1998 R-410Ab 0/1900 N/N 72.6 2 52.6 4.79 70.2 0.16 0.79 6763 1998 R-717 0/0 Y/Y 17.0 2 33.3 11.42 133.0 0.04 0.67 4382 1859 R-290 R-744 0/3 0/1 Y/N N/N 44.1 44.0 M.-H. Kim et al. / Progress in Energy and Combustion Science 30 (2004) 119–174 121 Nomenclature COP coefficient of performance cp specific heat, kJ/kg K Teai evaporator air inlet temperature, 8C Tex refrigerant temperature at the exit of gas cooler, 8C T0 evaporating temperature, 8C TEWI total equivalent warming impact V volume, m3 Vc outdoor air flow rate, m3/min Ve indoor air flow rate, m3/min v specific volume, m3/kg w specific compressor work, kJ/kg x quality 1 effectiveness his isentropic efficiency k thermal conductivity, W/m K l volumetric efficiency m viscosity, kg/m s p pressure ratio r density, kg/m3 s surface tension, N/m Fc compressor torque, N m 2 G mass flux, kg/m s GWP global warming potential h enthalpy, kJ/kg HPF heating performance factor HSPF heating seasonal performance factor HX heat exchanger IHX internal heat exchanger (suction-line liquid-line heat exchanger) L internal heat exchanger length, m LMTD log mean temperature difference, 8C or K m refrigerant charge, kg mr refrigerant mass flow rate, g/s NTU number of transfer unit ODP ozone depletion potential P pressure, bar or MPa pm mean effective pressure, bar Pr Prandtl number Subscripts Q capacity, kW q heat flux, kW/m2 q0 specific refrigeration capacity, kW/kg qv volumetric refrigeration capacity, kJ/m3 RH relative humidity, % s entropy, kJ/kg K SPF seasonal performance factor T temperature, 8C or K f liquid g vapor max maximum opt optimum pseudo pseudocritical state ref reference point 2 42.1 4.25 7.38 96.7 31.1 0.11 0.47 0.74 0.90 3907 22545 ? 1869 2 78.4 a Ternary mixture of R-32/125/134a (23/25/52, %). b Binary mixture of R-32/125 (50/50, %). c Global warming potential in relation to 100 years integration time, from the Intergovernmental Panel on Climate Change (IPCC). d ASRAE handbook 2001 fundamentals. e Ratio of saturation pressure at 0 8C to critical pressure. f Ratio of 273.15 K (0 8C) to critical temperature in Kelvin. g Volumetric refrigeration capacity at 0 8C.PDF Image | CO2 Vapor Compression Systems

PDF Search Title:

CO2 Vapor Compression SystemsOriginal File Name Searched:

co2-vapor-compression-systems.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |