PDF Publication Title:

Text from PDF Page: 004

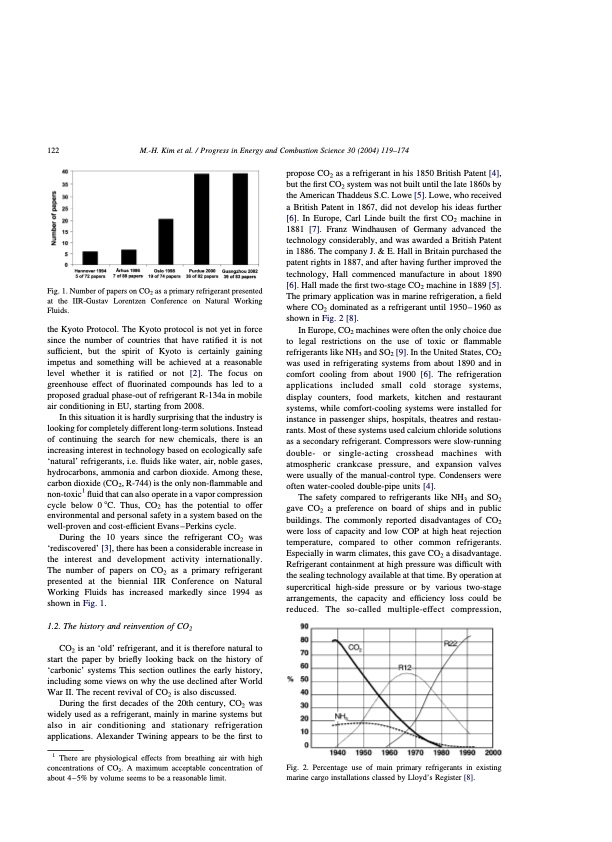

122 M.-H. Kim et al. / Progress in Energy and Combustion Science 30 (2004) 119–174 Fig. 1. Number of papers on CO2 as a primary refrigerant presented at the IIR-Gustav Lorentzen Conference on Natural Working Fluids. the Kyoto Protocol. The Kyoto protocol is not yet in force since the number of countries that have ratified it is not sufficient, but the spirit of Kyoto is certainly gaining impetus and something will be achieved at a reasonable level whether it is ratified or not [2]. The focus on greenhouse effect of fluorinated compounds has led to a proposed gradual phase-out of refrigerant R-134a in mobile air conditioning in EU, starting from 2008. In this situation it is hardly surprising that the industry is looking for completely different long-term solutions. Instead of continuing the search for new chemicals, there is an increasing interest in technology based on ecologically safe ‘natural’ refrigerants, i.e. fluids like water, air, noble gases, hydrocarbons, ammonia and carbon dioxide. Among these, carbon dioxide (CO2, R-744) is the only non-flammable and non-toxic1 fluid that can also operate in a vapor compression cycle below 0 8C. Thus, CO2 has the potential to offer environmental and personal safety in a system based on the well-proven and cost-efficient Evans–Perkins cycle. During the 10 years since the refrigerant CO2 was ‘rediscovered’ [3], there has been a considerable increase in the interest and development activity internationally. The number of papers on CO2 as a primary refrigerant presented at the biennial IIR Conference on Natural Working Fluids has increased markedly since 1994 as shown in Fig. 1. 1.2. The history and reinvention of CO2 CO2 is an ‘old’ refrigerant, and it is therefore natural to start the paper by briefly looking back on the history of ‘carbonic’ systems This section outlines the early history, including some views on why the use declined after World War II. The recent revival of CO2 is also discussed. During the first decades of the 20th century, CO2 was widely used as a refrigerant, mainly in marine systems but also in air conditioning and stationary refrigeration applications. Alexander Twining appears to be the first to 1 There are physiological effects from breathing air with high concentrations of CO2. A maximum acceptable concentration of about 4–5% by volume seems to be a reasonable limit. propose CO2 as a refrigerant in his 1850 British Patent [4], but the first CO2 system was not built until the late 1860s by the American Thaddeus S.C. Lowe [5]. Lowe, who received a British Patent in 1867, did not develop his ideas further [6]. In Europe, Carl Linde built the first CO2 machine in 1881 [7]. Franz Windhausen of Germany advanced the technology considerably, and was awarded a British Patent in 1886. The company J. & E. Hall in Britain purchased the patent rights in 1887, and after having further improved the technology, Hall commenced manufacture in about 1890 [6]. Hall made the first two-stage CO2 machine in 1889 [5]. The primary application was in marine refrigeration, a field where CO2 dominated as a refrigerant until 1950–1960 as shown in Fig. 2 [8]. In Europe, CO2 machines were often the only choice due to legal restrictions on the use of toxic or flammable refrigerants like NH3 and SO2 [9]. In the United States, CO2 was used in refrigerating systems from about 1890 and in comfort cooling from about 1900 [6]. The refrigeration applications included small cold storage systems, display counters, food markets, kitchen and restaurant systems, while comfort-cooling systems were installed for instance in passenger ships, hospitals, theatres and restau- rants. Most of these systems used calcium chloride solutions as a secondary refrigerant. Compressors were slow-running double- or single-acting crosshead machines with atmospheric crankcase pressure, and expansion valves were usually of the manual-control type. Condensers were often water-cooled double-pipe units [4]. The safety compared to refrigerants like NH3 and SO2 gave CO2 a preference on board of ships and in public buildings. The commonly reported disadvantages of CO2 were loss of capacity and low COP at high heat rejection temperature, compared to other common refrigerants. Especially in warm climates, this gave CO2 a disadvantage. Refrigerant containment at high pressure was difficult with the sealing technology available at that time. By operation at supercritical high-side pressure or by various two-stage arrangements, the capacity and efficiency loss could be reduced. The so-called multiple-effect compression, Fig. 2. Percentage use of main primary refrigerants in existing marine cargo installations classed by Lloyd’s Register [8].PDF Image | CO2 Vapor Compression Systems

PDF Search Title:

CO2 Vapor Compression SystemsOriginal File Name Searched:

co2-vapor-compression-systems.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |