PDF Publication Title:

Text from PDF Page: 003

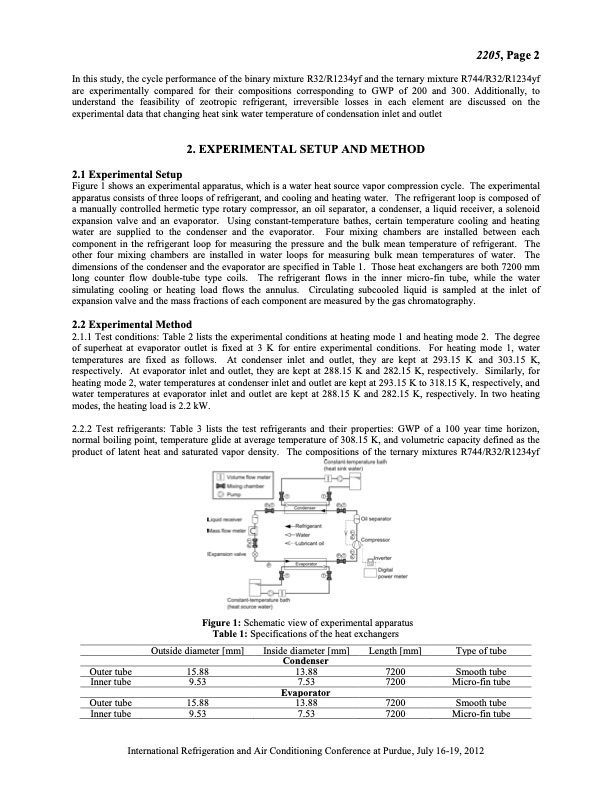

2205, Page 2 In this study, the cycle performance of the binary mixture R32/R1234yf and the ternary mixture R744/R32/R1234yf are experimentally compared for their compositions corresponding to GWP of 200 and 300. Additionally, to understand the feasibility of zeotropic refrigerant, irreversible losses in each element are discussed on the experimental data that changing heat sink water temperature of condensation inlet and outlet 2. EXPERIMENTAL SETUP AND METHOD 2.1 Experimental Setup Figure 1 shows an experimental apparatus, which is a water heat source vapor compression cycle. The experimental apparatus consists of three loops of refrigerant, and cooling and heating water. The refrigerant loop is composed of a manually controlled hermetic type rotary compressor, an oil separator, a condenser, a liquid receiver, a solenoid expansion valve and an evaporator. Using constant-temperature bathes, certain temperature cooling and heating water are supplied to the condenser and the evaporator. Four mixing chambers are installed between each component in the refrigerant loop for measuring the pressure and the bulk mean temperature of refrigerant. The other four mixing chambers are installed in water loops for measuring bulk mean temperatures of water. The dimensions of the condenser and the evaporator are specified in Table 1. Those heat exchangers are both 7200 mm long counter flow double-tube type coils. The refrigerant flows in the inner micro-fin tube, while the water simulating cooling or heating load flows the annulus. Circulating subcooled liquid is sampled at the inlet of expansion valve and the mass fractions of each component are measured by the gas chromatography. 2.2 Experimental Method 2.1.1 Test conditions: Table 2 lists the experimental conditions at heating mode 1 and heating mode 2. The degree of superheat at evaporator outlet is fixed at 3 K for entire experimental conditions. For heating mode 1, water temperatures are fixed as follows. At condenser inlet and outlet, they are kept at 293.15 K and 303.15 K, respectively. At evaporator inlet and outlet, they are kept at 288.15 K and 282.15 K, respectively. Similarly, for heating mode 2, water temperatures at condenser inlet and outlet are kept at 293.15 K to 318.15 K, respectively, and water temperatures at evaporator inlet and outlet are kept at 288.15 K and 282.15 K, respectively. In two heating modes, the heating load is 2.2 kW. 2.2.2 Test refrigerants: Table 3 lists the test refrigerants and their properties: GWP of a 100 year time horizon, normal boiling point, temperature glide at average temperature of 308.15 K, and volumetric capacity defined as the product of latent heat and saturated vapor density. The compositions of the ternary mixtures R744/R32/R1234yf Figure 1: Schematic view of experimental apparatus Outer tube Inner tube Outer tube Inner tube Outside diameter [mm] 15.88 9.53 15.88 9.53 Inside diameter [mm] Condenser 13.88 7.53 Evaporator 13.88 7.53 Length [mm] 7200 7200 7200 7200 Type of tube Smooth tube Micro-fin tube Smooth tube Micro-fin tube Table 1: Specifications of the heat exchangers International Refrigeration and Air Conditioning Conference at Purdue, July 16-19, 2012PDF Image | Experimental Assessment on Performance of a Heat Pump Cycle

PDF Search Title:

Experimental Assessment on Performance of a Heat Pump CycleOriginal File Name Searched:

heat-pump-cycle-analysis.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |