PDF Publication Title:

Text from PDF Page: 028

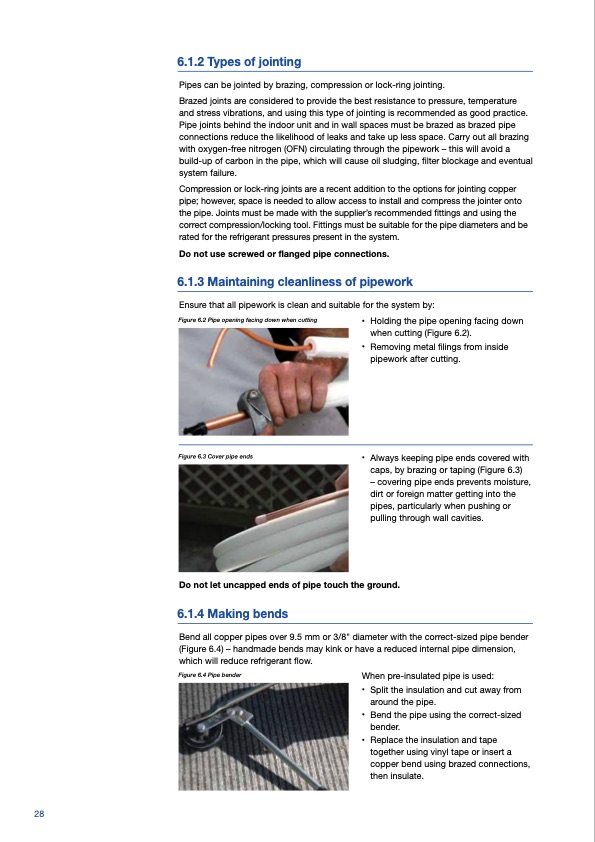

6.1.2 Types of jointing Pipes can be jointed by brazing, compression or lock-ring jointing. Brazed joints are considered to provide the best resistance to pressure, temperature and stress vibrations, and using this type of jointing is recommended as good practice. Pipe joints behind the indoor unit and in wall spaces must be brazed as brazed pipe connections reduce the likelihood of leaks and take up less space. Carry out all brazing with oxygen-free nitrogen (OFN) circulating through the pipework – this will avoid a build-up of carbon in the pipe, which will cause oil sludging, filter blockage and eventual system failure. Compression or lock-ring joints are a recent addition to the options for jointing copper pipe; however, space is needed to allow access to install and compress the jointer onto the pipe. Joints must be made with the supplier’s recommended fittings and using the correct compression/locking tool. Fittings must be suitable for the pipe diameters and be rated for the refrigerant pressures present in the system. Do not use screwed or flanged pipe connections. 6.1.3 Maintaining cleanliness of pipework Ensure that all pipework is clean and suitable for the system by: Figure 6.2 Pipe opening facing down when cutting • Holding the pipe opening facing down when cutting (Figure 6.2). • Removing metal filings from inside pipework after cutting. • Always keeping pipe ends covered with caps, by brazing or taping (Figure 6.3) – covering pipe ends prevents moisture, dirt or foreign matter getting into the pipes, particularly when pushing or pulling through wall cavities. Figure 6.3 Cover pipe ends 28 Do not let uncapped ends of pipe touch the ground. 6.1.4 Making bends Bend all copper pipes over 9.5 mm or 3/8" diameter with the correct-sized pipe bender (Figure 6.4) – handmade bends may kink or have a reduced internal pipe dimension, which will reduce refrigerant flow. Figure 6.4 Pipe bender When pre-insulated pipe is used: • Split the insulation and cut away from around the pipe. • Bend the pipe using the correct-sized bender. • Replace the insulation and tape together using vinyl tape or insert a copper bend using brazed connections, then insulate.PDF Image | Heat pump installation Good Practice Guide

PDF Search Title:

Heat pump installation Good Practice GuideOriginal File Name Searched:

Good_practice_heat_pump_installation.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |