PDF Publication Title:

Text from PDF Page: 029

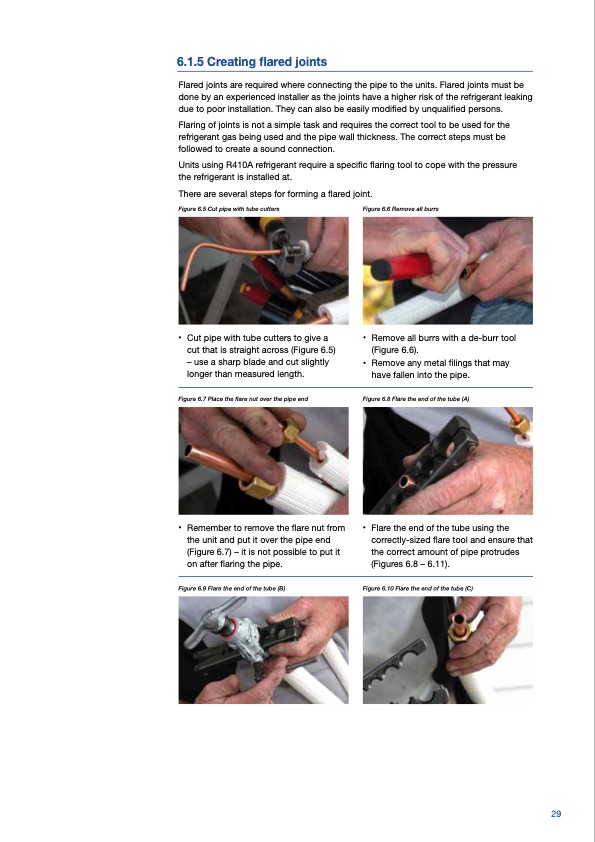

6.1.5 Creating flared joints Flared joints are required where connecting the pipe to the units. Flared joints must be done by an experienced installer as the joints have a higher risk of the refrigerant leaking due to poor installation. They can also be easily modified by unqualified persons. Flaring of joints is not a simple task and requires the correct tool to be used for the refrigerant gas being used and the pipe wall thickness. The correct steps must be followed to create a sound connection. Units using R410A refrigerant require a specific flaring tool to cope with the pressure the refrigerant is installed at. There are several steps for forming a flared joint. Figure 6.5 Cut pipe with tube cutters • Cut pipe with tube cutters to give a cut that is straight across (Figure 6.5) – use a sharp blade and cut slightly longer than measured length. Figure 6.7 Place the flare nut over the pipe end • Remember to remove the flare nut from the unit and put it over the pipe end (Figure 6.7) – it is not possible to put it on after flaring the pipe. Figure 6.9 Flare the end of the tube (B) Figure 6.6 Remove all burrs • Remove all burrs with a de-burr tool (Figure 6.6). • Remove any metal filings that may have fallen into the pipe. Figure 6.8 Flare the end of the tube (A) • Flare the end of the tube using the correctly-sized flare tool and ensure that the correct amount of pipe protrudes (Figures 6.8 – 6.11). Figure 6.10 Flare the end of the tube (C) 29PDF Image | Heat pump installation Good Practice Guide

PDF Search Title:

Heat pump installation Good Practice GuideOriginal File Name Searched:

Good_practice_heat_pump_installation.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |