PDF Publication Title:

Text from PDF Page: 030

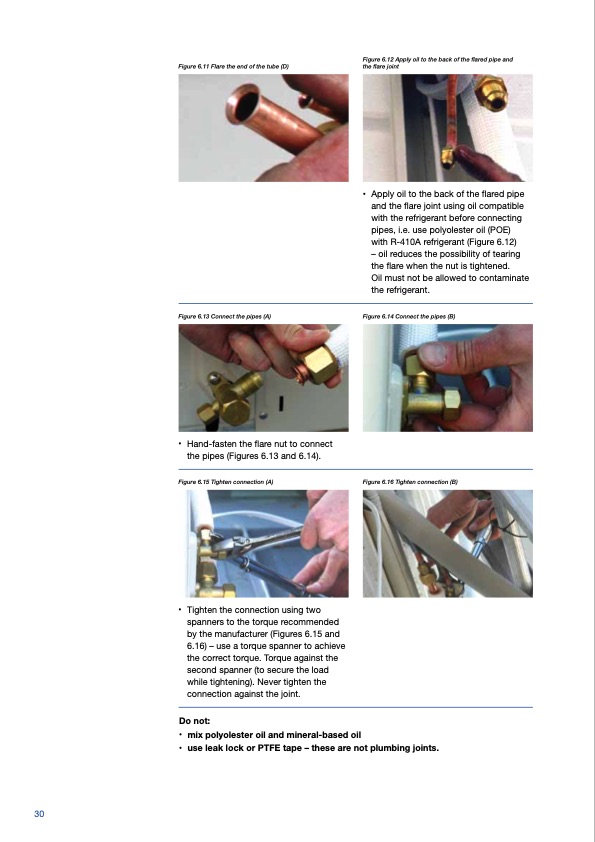

Figure 6.11 Flare the end of the tube (D) Figure 6.12 Apply oil to the back of the flared pipe and the flare joint • Apply oil to the back of the flared pipe and the flare joint using oil compatible with the refrigerant before connecting pipes, i.e. use polyolester oil (POE) with R-410A refrigerant (Figure 6.12) – oil reduces the possibility of tearing the flare when the nut is tightened. Oil must not be allowed to contaminate the refrigerant. Figure 6.14 Connect the pipes (B) Figure 6.13 Connect the pipes (A) • Hand-fasten the flare nut to connect the pipes (Figures 6.13 and 6.14). Figure 6.15 Tighten connection (A) • Tighten the connection using two spanners to the torque recommended by the manufacturer (Figures 6.15 and 6.16) – use a torque spanner to achieve the correct torque. Torque against the second spanner (to secure the load while tightening). Never tighten the connection against the joint. Figure 6.16 Tighten connection (B) 30 Do not: • mix polyolester oil and mineral-based oil • use leak lock or PTFE tape – these are not plumbing joints.PDF Image | Heat pump installation Good Practice Guide

PDF Search Title:

Heat pump installation Good Practice GuideOriginal File Name Searched:

Good_practice_heat_pump_installation.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |