PDF Publication Title:

Text from PDF Page: 031

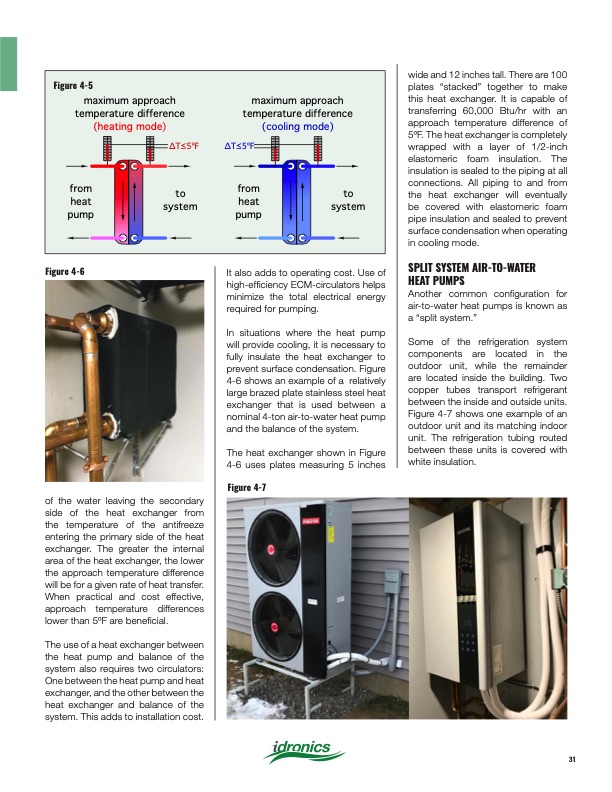

Figure 4-5 maximum approach temperature difference (heating mode) ∆T≤5oF to system maximum approach temperature difference (cooling mode) ∆T≤5oF from from to system heat pump heat pump Figure 4-6 It also adds to operating cost. Use of high-efficiency ECM-circulators helps minimize the total electrical energy required for pumping. In situations where the heat pump will provide cooling, it is necessary to fully insulate the heat exchanger to prevent surface condensation. Figure 4-6 shows an example of a relatively large brazed plate stainless steel heat exchanger that is used between a nominal 4-ton air-to-water heat pump and the balance of the system. The heat exchanger shown in Figure 4-6 uses plates measuring 5 inches Figure 4-7 wide and 12 inches tall. There are 100 plates “stacked” together to make this heat exchanger. It is capable of transferring 60,000 Btu/hr with an approach temperature difference of 5oF. The heat exchanger is completely wrapped with a layer of 1/2-inch elastomeric foam insulation. The insulation is sealed to the piping at all connections. All piping to and from the heat exchanger will eventually be covered with elastomeric foam pipe insulation and sealed to prevent surface condensation when operating in cooling mode. SPLIT SYSTEM AIR-TO-WATER HEAT PUMPS Another common configuration for air-to-water heat pumps is known as a “split system.” Some of the refrigeration system components are located in the outdoor unit, while the remainder are located inside the building. Two copper tubes transport refrigerant between the inside and outside units. Figure 4-7 shows one example of an outdoor unit and its matching indoor unit. The refrigeration tubing routed between these units is covered with white insulation. of the water leaving the secondary side of the heat exchanger from the temperature of the antifreeze entering the primary side of the heat exchanger. The greater the internal area of the heat exchanger, the lower the approach temperature difference will be for a given rate of heat transfer. When practical and cost effective, approach temperature differences lower than 5oF are beneficial. The use of a heat exchanger between the heat pump and balance of the system also requires two circulators: One between the heat pump and heat exchanger, and the other between the heat exchanger and balance of the system. This adds to installation cost. 31PDF Image | Heat Pump Systems 2020

PDF Search Title:

Heat Pump Systems 2020Original File Name Searched:

idronics_27_na.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |