PDF Publication Title:

Text from PDF Page: 056

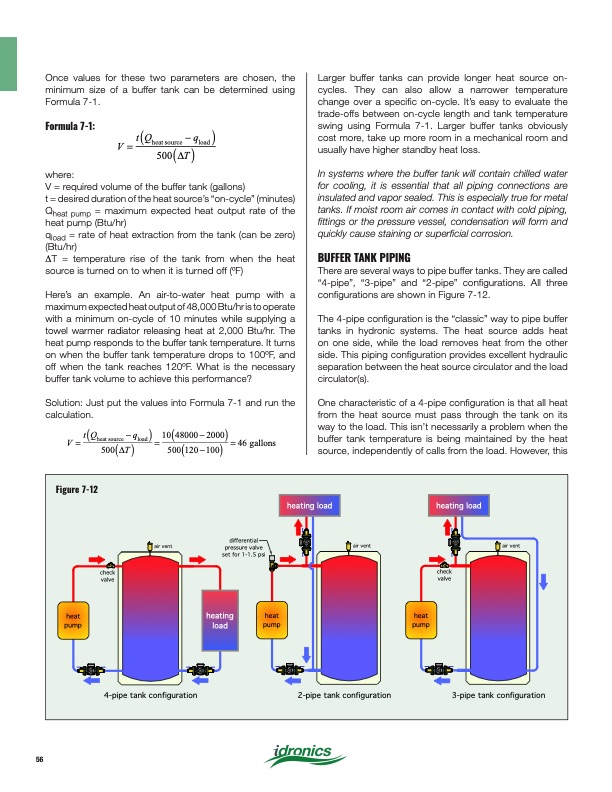

V = t (Qheat source − qload ) 500(ΔT) V =t(Qheatsource −qload)=10(48000−2000)=46gallons 500(ΔT) 500(120−100) Figure 7-12 COP ave heat pump = Btu delivered (kwhr used)× 3413 air vent heating load heating load differential pressure valve set for 1-1.5 psi heat pump air vent air vent check valve check valve 4-pipe tank configuration 2-pipe tank configuration 3-pipe tank configuration heating load heat pump q=0.8×(Twa −Troom) Once values for tqhe=se0.t7w1o×(pTaram−eTters)are chosen, the Larger buffer tanks can provide longer heat source on- cycles. They can also allow a narrower temperature change over a specific on-cycle. It’s easy to evaluate the trade-offs between on-cycle length and tank temperature swing using Formula 7-1. Larger buffer tanks obviously cost more, take up more room in a mechanical room and usually have higher standby heat loss. minimum size of a buffer tank can be determined using Formula 7-1. Formula 7-1: where: V = requ=irekd(Tvol−umT e o)f=th1e5 =bukf(f1e1r 5ta−n7k0()gallons) In systems where the buffer tank will contain chilled water for cooling, it is essential that all piping connections are insulated and vapor sealed. This is especially true for metal wa room t = desired duration oftthQe heat sou−rcqe’s “on-1c0yc4le8”0(0m0i−nu2t0e0s0) 15 ( heatsource load) ( ) k = V=0.333 Q = maximum expected heat output rate of the 115−70 500(ΔT) 500(120−100) heat pump (Btu/hr) qload = rate of heat extraction from the tank (can be zero) (Btu/hr) ∆T = temperature rise of the tank from when the heat Btu delivered heat pump source is turned on to when it is turned off (oF) BUFFER TANK PIPING There are several ways to pipe buffer tanks. They are called “4-pipe”, “3-pipe” and “2-pipe” configurations. All three configurations are shown in Figure 7-12. The 4-pipe configuration is the “classic” way to pipe buffer tanks in hydronic systems. The heat source adds heat on one side, while the load removes heat from the other side. This piping configuration provides excellent hydraulic separation between the heat source circulator and the load circulator(s). One characteristic of a 4-pipe configuration is that all heat from the heat source must pass through the tank on its way to the load. This isn’t necessarily a problem when the buffer tank temperature is being maintained by the heat source, independently of calls from the load. However, this q=0.8×(Twa −Troom) Here’s an example. An air-to-water heat pump with a COP = ave maximum expected heat outp(ukt owfh4r8,u0s0e0dB)t×u/3h4r1is3to operate with a minimum on-cycle of 10 minutes while supplying a q=0.71×(T −T ) towel warmer radiator releasing heat at 2,000 Btu/hr. The wa room heat pump responds to the buffer tank temperature. It turns on when the buffer tank temperature drops to 100oF, and off when the tank reaches 120oF. What is the necessary buffer tank volume to achieve this performance? V = t (Qheat source − qload ) 500(ΔT) Solution: Just put the values into Formula 7-1 and run the calculation. wa room = = 4t6angkasll.oInfsmoist room air comes in contact with cold piping, fittings or the pressure vessel, condensation will form and quickly cause staining or superficial corrosion. 56PDF Image | Heat Pump Systems 2020

PDF Search Title:

Heat Pump Systems 2020Original File Name Searched:

idronics_27_na.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |