PDF Publication Title:

Text from PDF Page: 016

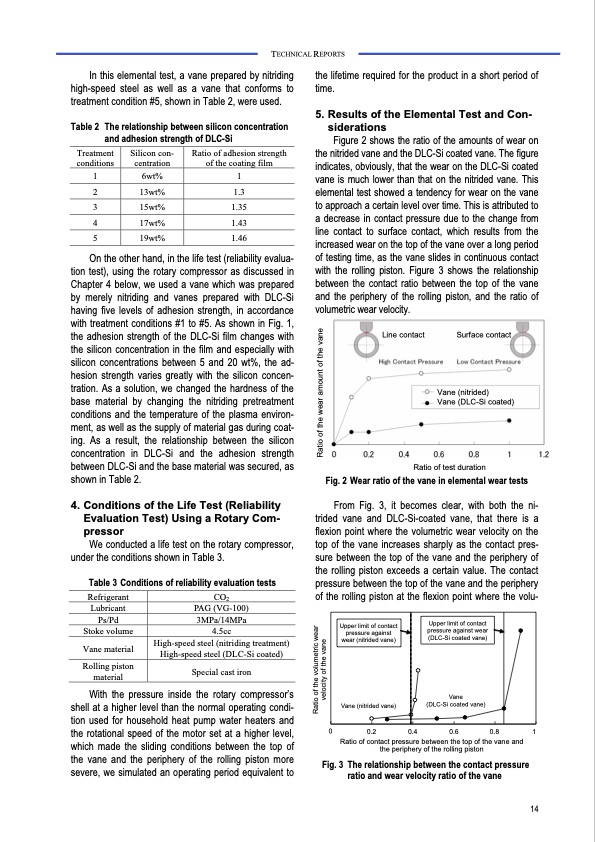

In this elemental test, a vane prepared by nitriding high-speed steel as well as a vane that conforms to treatment condition #5, shown in Table 2, were used. Table2 Therelationshipbetweensiliconconcentration and adhesion strength of DLC-Si the lifetime required for the product in a short period of time. 5. Results of the Elemental Test and Con- siderations Figure 2 shows the ratio of the amounts of wear on the nitrided vane and the DLC-Si coated vane. The figure indicates, obviously, that the wear on the DLC-Si coated vane is much lower than that on the nitrided vane. This elemental test showed a tendency for wear on the vane to approach a certain level over time. This is attributed to a decrease in contact pressure due to the change from line contact to surface contact, which results from the increased wear on the top of the vane over a long period of testing time, as the vane slides in continuous contact with the rolling piston. Figure 3 shows the relationship between the contact ratio between the top of the vane and the periphery of the rolling piston, and the ratio of volumetric wear velocity. TECHNICAL REPORTS Treatment conditions Silicon con- Ratio of adhesion strength centration of the coating film 6wt% 1 1 2 13wt% 1.3 3 15wt% 4 17wt% 1.43 5 19wt% 1.46 On the other hand, in the life test (reliability evalua- tion test), using the rotary compressor as discussed in Chapter 4 below, we used a vane which was prepared by merely nitriding and vanes prepared with DLC-Si having five levels of adhesion strength, in accordance with treatment conditions #1 to #5. As shown in Fig. 1, the adhesion strength of the DLC-Si film changes with the silicon concentration in the film and especially with silicon concentrations between 5 and 20 wt%, the ad- hesion strength varies greatly with the silicon concen- tration. As a solution, we changed the hardness of the base material by changing the nitriding pretreatment conditions and the temperature of the plasma environ- ment, as well as the supply of material gas during coat- ing. As a result, the relationship between the silicon concentration in DLC-Si and the adhesion strength between DLC-Si and the base material was secured, as shown in Table 2. 4. Conditions of the Life Test (Reliability Evaluation Test) Using a Rotary Com- pressor We conducted a life test on the rotary compressor, under the conditions shown in Table 3. Table 3 Conditions of reliability evaluation tests 1.35 Refrigerant Lubricant Ps/Pd Stoke volume Vane material Rolling piston material CO2 PAG (VG-100) 3MPa/14MPa 4.5cc High-speed steel (nitriding treatment) High-speed steel (DLC-Si coated) Special cast iron Ratio of test duration Fig. 2 Wear ratio of the vane in elemental wear tests From Fig. 3, it becomes clear, with both the ni- trided vane and DLC-Si-coated vane, that there is a flexion point where the volumetric wear velocity on the top of the vane increases sharply as the contact pres- sure between the top of the vane and the periphery of the rolling piston exceeds a certain value. The contact pressure between the top of the vane and the periphery of the rolling piston at the flexion point where the volu- Line contact Surface contact Vane (nitrided) Vane (DLC-Si coated) Upper limit of contact pressure against wear (nitrided vane) Vane (nitrided vane) Upper limit of contact pressure against wear (DLC-Si coated vane) Vane (DLC-Si coated vane) 0 0.2 0.4 0.6 0.8 1 Ratio of contact pressure between the top of the vane and the periphery of the rolling piston With the pressure inside the rotary compressor’s shell at a higher level than the normal operating condi- tion used for household heat pump water heaters and the rotational speed of the motor set at a higher level, which made the sliding conditions between the top of the vane and the periphery of the rolling piston more severe, we simulated an operating period equivalent to Fig. 3 The relationship between the contact pressure ratio and wear velocity ratio of the vane 14 Ratio of the volumetric wear velocity of the vane Ratio of the wear amount of the vanePDF Image | Heat Pump with Natural Refrigerants 3041

PDF Search Title:

Heat Pump with Natural Refrigerants 3041Original File Name Searched:

vol120.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |