PDF Publication Title:

Text from PDF Page: 017

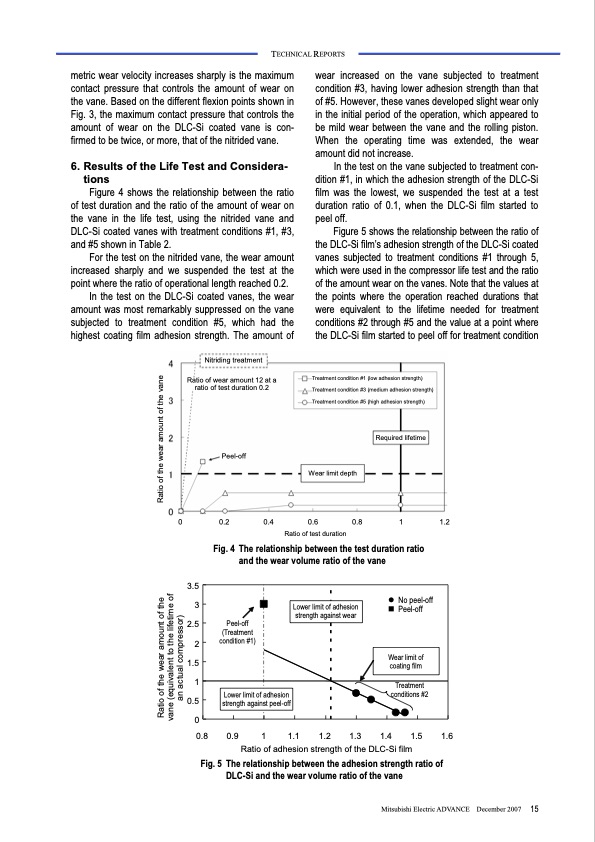

3.5 3 2.5 2 1.5 1 0.5 0 0.8 0.9 1 1.1 1.2 1.3 1.4 1.5 1.6 TECHNICAL REPORTS wear increased on the vane subjected to treatment condition #3, having lower adhesion strength than that of #5. However, these vanes developed slight wear only in the initial period of the operation, which appeared to be mild wear between the vane and the rolling piston. When the operating time was extended, the wear amount did not increase. In the test on the vane subjected to treatment con- dition #1, in which the adhesion strength of the DLC-Si film was the lowest, we suspended the test at a test duration ratio of 0.1, when the DLC-Si film started to peel off. Figure 5 shows the relationship between the ratio of the DLC-Si film’s adhesion strength of the DLC-Si coated vanes subjected to treatment conditions #1 through 5, which were used in the compressor life test and the ratio of the amount wear on the vanes. Note that the values at the points where the operation reached durations that were equivalent to the lifetime needed for treatment conditions #2 through #5 and the value at a point where the DLC-Si film started to peel off for treatment condition Treatment condition #1 (low adhesion strength) Treatment condition #3 (medium adhesion strength) Treatment condition #5 (high adhesion strength) Required lifetime Wear limit depth 0 0.2 0.4 0.6 0.8 1 1.2 Ratio of test duration Fig. 4 The relationship between the test duration ratio and the wear volume ratio of the vane metric wear velocity increases sharply is the maximum contact pressure that controls the amount of wear on the vane. Based on the different flexion points shown in Fig. 3, the maximum contact pressure that controls the amount of wear on the DLC-Si coated vane is con- firmed to be twice, or more, that of the nitrided vane. 6. Results of the Life Test and Considera- tions Figure 4 shows the relationship between the ratio of test duration and the ratio of the amount of wear on the vane in the life test, using the nitrided vane and DLC-Si coated vanes with treatment conditions #1, #3, and #5 shown in Table 2. For the test on the nitrided vane, the wear amount increased sharply and we suspended the test at the point where the ratio of operational length reached 0.2. In the test on the DLC-Si coated vanes, the wear amount was most remarkably suppressed on the vane subjected to treatment condition #5, which had the highest coating film adhesion strength. The amount of Nitriding treatment Ratio of wear amount 12 at a ratio of test duration 0.2 Peel-off � No peel-off Peel-off (Treatment condition #1) Lower limit of adhesion strength against wear � Peel-off Wear limit of coating film Treatment conditions #2 Lower limit of adhesion strength against peel-off Ratio of adhesion strength of the DLC-Si film Fig. 5 The relationship between the adhesion strength ratio of DLC-Si and the wear volume ratio of the vane Mitsubishi Electric ADVANCE December 2007 15 Ratio of the wear amount of the Ratio of the wear amount of the vane vane (equivalent to the lifetime of an actual compressor)PDF Image | Heat Pump with Natural Refrigerants 3041

PDF Search Title:

Heat Pump with Natural Refrigerants 3041Original File Name Searched:

vol120.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |