PDF Publication Title:

Text from PDF Page: 010

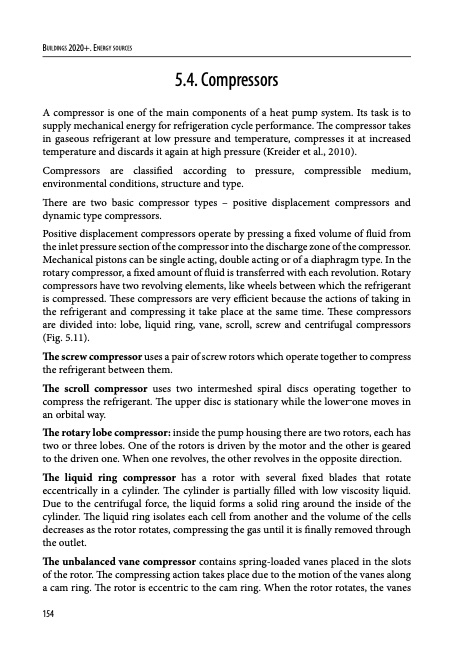

Buildings 2020+. EnErgy sourcEs 5.4. Compressors A compressor is one of the main components of a heat pump system. Its task is to supply mechanical energy for refrigeration cycle performance. The compressor takes in gaseous refrigerant at low pressure and temperature, compresses it at increased temperature and discards it again at high pressure (Kreider et al., 2010). Compressors are classified according to pressure, compressible medium, environmental conditions, structure and type. There are two basic compressor types – positive displacement compressors and dynamic type compressors. Positive displacement compressors operate by pressing a fixed volume of fluid from the inlet pressure section of the compressor into the discharge zone of the compressor. Mechanical pistons can be single acting, double acting or of a diaphragm type. In the rotary compressor, a fixed amount of fluid is transferred with each revolution. Rotary compressors have two revolving elements, like wheels between which the refrigerant is compressed. These compressors are very efficient because the actions of taking in the refrigerant and compressing it take place at the same time. These compressors are divided into: lobe, liquid ring, vane, scroll, screw and centrifugal compressors (Fig. 5.11). The screw compressor uses a pair of screw rotors which operate together to compress the refrigerant between them. The scroll compressor uses two intermeshed spiral discs operating together to compress the refrigerant. The upper disc is stationary while the lower one moves in an orbital way. The rotary lobe compressor: inside the pump housing there are two rotors, each has two or three lobes. One of the rotors is driven by the motor and the other is geared to the driven one. When one revolves, the other revolves in the opposite direction. The liquid ring compressor has a rotor with several fixed blades that rotate eccentrically in a cylinder. The cylinder is partially filled with low viscosity liquid. Due to the centrifugal force, the liquid forms a solid ring around the inside of the cylinder. The liquid ring isolates each cell from another and the volume of the cells decreases as the rotor rotates, compressing the gas until it is finally removed through the outlet. The unbalanced vane compressor contains spring-loaded vanes placed in the slots of the rotor. The compressing action takes place due to the motion of the vanes along a cam ring. The rotor is eccentric to the cam ring. When the rotor rotates, the vanes 154PDF Image | Heat Pumps 978-83-65596-73-4

PDF Search Title:

Heat Pumps 978-83-65596-73-4Original File Name Searched:

Buildings-2020-part2-rozdz5.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |