PDF Publication Title:

Text from PDF Page: 097

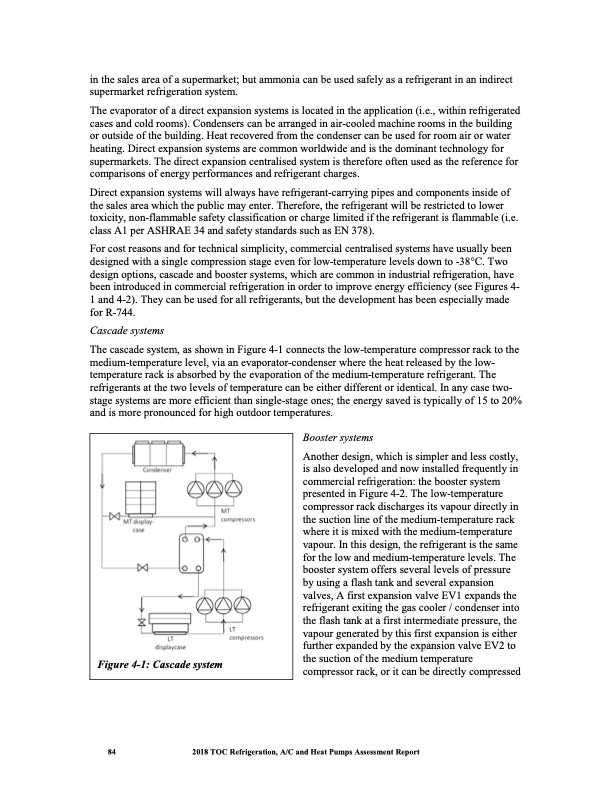

in the sales area of a supermarket; but ammonia can be used safely as a refrigerant in an indirect supermarket refrigeration system. The evaporator of a direct expansion systems is located in the application (i.e., within refrigerated cases and cold rooms). Condensers can be arranged in air-cooled machine rooms in the building or outside of the building. Heat recovered from the condenser can be used for room air or water heating. Direct expansion systems are common worldwide and is the dominant technology for supermarkets. The direct expansion centralised system is therefore often used as the reference for comparisons of energy performances and refrigerant charges. Direct expansion systems will always have refrigerant-carrying pipes and components inside of the sales area which the public may enter. Therefore, the refrigerant will be restricted to lower toxicity, non-flammable safety classification or charge limited if the refrigerant is flammable (i.e. class A1 per ASHRAE 34 and safety standards such as EN 378). For cost reasons and for technical simplicity, commercial centralised systems have usually been designed with a single compression stage even for low-temperature levels down to -38°C. Two design options, cascade and booster systems, which are common in industrial refrigeration, have been introduced in commercial refrigeration in order to improve energy efficiency (see Figures 4- 1 and 4-2). They can be used for all refrigerants, but the development has been especially made for R-744. Cascade systems The cascade system, as shown in Figure 4-1 connects the low-temperature compressor rack to the medium-temperature level, via an evaporator-condenser where the heat released by the low- temperature rack is absorbed by the evaporation of the medium-temperature refrigerant. The refrigerants at the two levels of temperature can be either different or identical. In any case two- stage systems are more efficient than single-stage ones; the energy saved is typically of 15 to 20% and is more pronounced for high outdoor temperatures. Booster systems Another design, which is simpler and less costly, is also developed and now installed frequently in commercial refrigeration: the booster system presented in Figure 4-2. The low-temperature compressor rack discharges its vapour directly in the suction line of the medium-temperature rack where it is mixed with the medium-temperature vapour. In this design, the refrigerant is the same for the low and medium-temperature levels. The booster system offers several levels of pressure by using a flash tank and several expansion valves, A first expansion valve EV1 expands the refrigerant exiting the gas cooler / condenser into the flash tank at a first intermediate pressure, the vapour generated by this first expansion is either further expanded by the expansion valve EV2 to the suction of the medium temperature compressor rack, or it can be directly compressed Figure 4-1: Cascade system 84 2018 TOC Refrigeration, A/C and Heat Pumps Assessment ReportPDF Image | Heat Pumps Technical Options

PDF Search Title:

Heat Pumps Technical OptionsOriginal File Name Searched:

RTOC-assessment-report-2018_0.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |