PDF Publication Title:

Text from PDF Page: 099

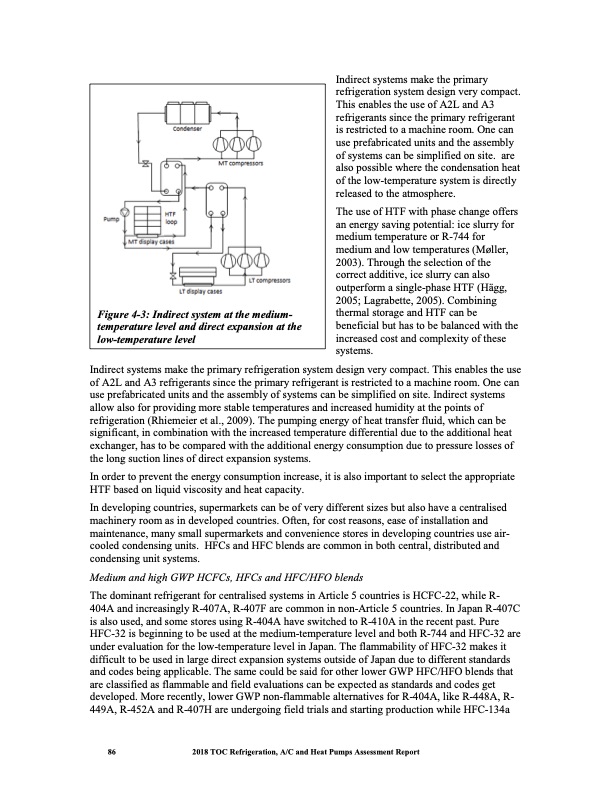

Indirect systems make the primary refrigeration system design very compact. This enables the use of A2L and A3 refrigerants since the primary refrigerant is restricted to a machine room. One can use prefabricated units and the assembly of systems can be simplified on site. are also possible where the condensation heat of the low-temperature system is directly released to the atmosphere. The use of HTF with phase change offers an energy saving potential: ice slurry for medium temperature or R-744 for medium and low temperatures (Møller, 2003). Through the selection of the correct additive, ice slurry can also outperform a single-phase HTF (Hägg, 2005; Lagrabette, 2005). Combining thermal storage and HTF can be beneficial but has to be balanced with the increased cost and complexity of these systems. Indirect systems make the primary refrigeration system design very compact. This enables the use of A2L and A3 refrigerants since the primary refrigerant is restricted to a machine room. One can use prefabricated units and the assembly of systems can be simplified on site. Indirect systems allow also for providing more stable temperatures and increased humidity at the points of refrigeration (Rhiemeier et al., 2009). The pumping energy of heat transfer fluid, which can be significant, in combination with the increased temperature differential due to the additional heat exchanger, has to be compared with the additional energy consumption due to pressure losses of the long suction lines of direct expansion systems. In order to prevent the energy consumption increase, it is also important to select the appropriate HTF based on liquid viscosity and heat capacity. In developing countries, supermarkets can be of very different sizes but also have a centralised machinery room as in developed countries. Often, for cost reasons, ease of installation and maintenance, many small supermarkets and convenience stores in developing countries use air- cooled condensing units. HFCs and HFC blends are common in both central, distributed and condensing unit systems. Medium and high GWP HCFCs, HFCs and HFC/HFO blends The dominant refrigerant for centralised systems in Article 5 countries is HCFC-22, while R- 404A and increasingly R-407A, R-407F are common in non-Article 5 countries. In Japan R-407C is also used, and some stores using R-404A have switched to R-410A in the recent past. Pure HFC-32 is beginning to be used at the medium-temperature level and both R-744 and HFC-32 are under evaluation for the low-temperature level in Japan. The flammability of HFC-32 makes it difficult to be used in large direct expansion systems outside of Japan due to different standards and codes being applicable. The same could be said for other lower GWP HFC/HFO blends that are classified as flammable and field evaluations can be expected as standards and codes get developed. More recently, lower GWP non-flammable alternatives for R-404A, like R-448A, R- 449A, R-452A and R-407H are undergoing field trials and starting production while HFC-134a Figure 4-3: Indirect system at the medium- temperature level and direct expansion at the low-temperature level 86 2018 TOC Refrigeration, A/C and Heat Pumps Assessment ReportPDF Image | Heat Pumps Technical Options

PDF Search Title:

Heat Pumps Technical OptionsOriginal File Name Searched:

RTOC-assessment-report-2018_0.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |