PDF Publication Title:

Text from PDF Page: 010

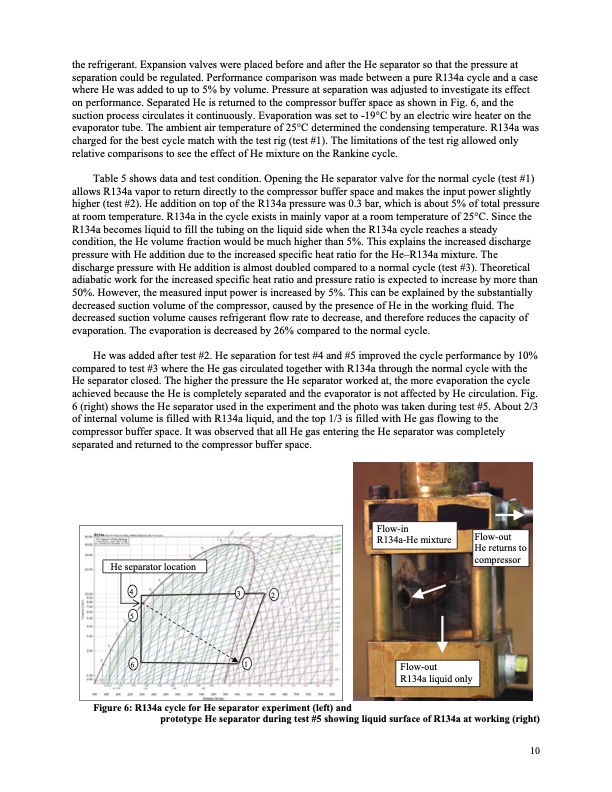

the refrigerant. Expansion valves were placed before and after the He separator so that the pressure at separation could be regulated. Performance comparison was made between a pure R134a cycle and a case where He was added to up to 5% by volume. Pressure at separation was adjusted to investigate its effect on performance. Separated He is returned to the compressor buffer space as shown in Fig. 6, and the suction process circulates it continuously. Evaporation was set to -19°C by an electric wire heater on the evaporator tube. The ambient air temperature of 25°C determined the condensing temperature. R134a was charged for the best cycle match with the test rig (test #1). The limitations of the test rig allowed only relative comparisons to see the effect of He mixture on the Rankine cycle. Table 5 shows data and test condition. Opening the He separator valve for the normal cycle (test #1) allows R134a vapor to return directly to the compressor buffer space and makes the input power slightly higher (test #2). He addition on top of the R134a pressure was 0.3 bar, which is about 5% of total pressure at room temperature. R134a in the cycle exists in mainly vapor at a room temperature of 25°C. Since the R134a becomes liquid to fill the tubing on the liquid side when the R134a cycle reaches a steady condition, the He volume fraction would be much higher than 5%. This explains the increased discharge pressure with He addition due to the increased specific heat ratio for the He–R134a mixture. The discharge pressure with He addition is almost doubled compared to a normal cycle (test #3). Theoretical adiabatic work for the increased specific heat ratio and pressure ratio is expected to increase by more than 50%. However, the measured input power is increased by 5%. This can be explained by the substantially decreased suction volume of the compressor, caused by the presence of He in the working fluid. The decreased suction volume causes refrigerant flow rate to decrease, and therefore reduces the capacity of evaporation. The evaporation is decreased by 26% compared to the normal cycle. He was added after test #2. He separation for test #4 and #5 improved the cycle performance by 10% compared to test #3 where the He gas circulated together with R134a through the normal cycle with the He separator closed. The higher the pressure the He separator worked at, the more evaporation the cycle achieved because the He is completely separated and the evaporator is not affected by He circulation. Fig. 6 (right) shows the He separator used in the experiment and the photo was taken during test #5. About 2/3 of internal volume is filled with R134a liquid, and the top 1/3 is filled with He gas flowing to the compressor buffer space. It was observed that all He gas entering the He separator was completely separated and returned to the compressor buffer space. Figure 6: R134a cycle for He separator experiment (left) and prototype He separator during test #5 showing liquid surface of R134a at working (right) Flow-in R134a-He mixture He separator location 4 5 3 2 61 Flow-out He returns to compressor Flow-out R134a liquid only 10PDF Image | HERMETIC GAS FIRED RESIDENTIAL HEAT PUMP

PDF Search Title:

HERMETIC GAS FIRED RESIDENTIAL HEAT PUMPOriginal File Name Searched:

Gas_Fired_Heat_Pump.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |