PDF Publication Title:

Text from PDF Page: 020

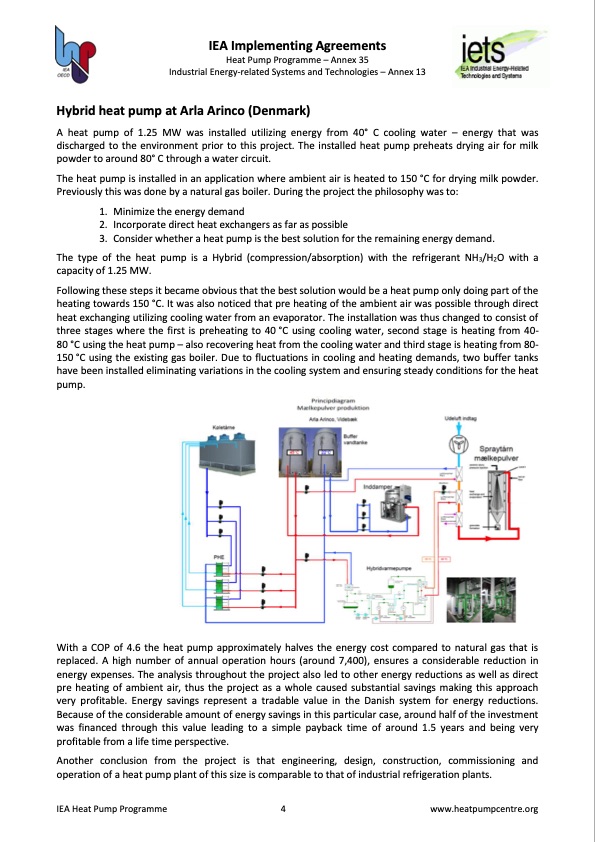

IEA Implementing Agreements Heat Pump Programme – Annex 35 Industrial Energy-related Systems and Technologies – Annex 13 Hybrid heat pump at Arla Arinco (Denmark) A heat pump of 1.25 MW was installed utilizing energy from 40° C cooling water – energy that was discharged to the environment prior to this project. The installed heat pump preheats drying air for milk powder to around 80° C through a water circuit. The heat pump is installed in an application where ambient air is heated to 150 °C for drying milk powder. Previously this was done by a natural gas boiler. During the project the philosophy was to: 1. Minimizetheenergydemand 2. Incorporate direct heat exchangers as far as possible 3. Consider whether a heat pump is the best solution for the remaining energy demand. The type of the heat pump is a Hybrid (compression/absorption) with the refrigerant NH3/H2O with a capacity of 1.25 MW. Following these steps it became obvious that the best solution would be a heat pump only doing part of the heating towards 150 °C. It was also noticed that pre heating of the ambient air was possible through direct heat exchanging utilizing cooling water from an evaporator. The installation was thus changed to consist of three stages where the first is preheating to 40 °C using cooling water, second stage is heating from 40- 80 °C using the heat pump – also recovering heat from the cooling water and third stage is heating from 80- 150 °C using the existing gas boiler. Due to fluctuations in cooling and heating demands, two buffer tanks have been installed eliminating variations in the cooling system and ensuring steady conditions for the heat pump. With a COP of 4.6 the heat pump approximately halves the energy cost compared to natural gas that is replaced. A high number of annual operation hours (around 7,400), ensures a considerable reduction in energy expenses. The analysis throughout the project also led to other energy reductions as well as direct pre heating of ambient air, thus the project as a whole caused substantial savings making this approach very profitable. Energy savings represent a tradable value in the Danish system for energy reductions. Because of the considerable amount of energy savings in this particular case, around half of the investment was financed through this value leading to a simple payback time of around 1.5 years and being very profitable from a life time perspective. Another conclusion from the project is that engineering, design, construction, commissioning and operation of a heat pump plant of this size is comparable to that of industrial refrigeration plants. IEA Heat Pump Programme 4 www.heatpumpcentre.orgPDF Image | Industrial Heat Pumps

PDF Search Title:

Industrial Heat PumpsOriginal File Name Searched:

annex-xiii-part-a.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |