PDF Publication Title:

Text from PDF Page: 021

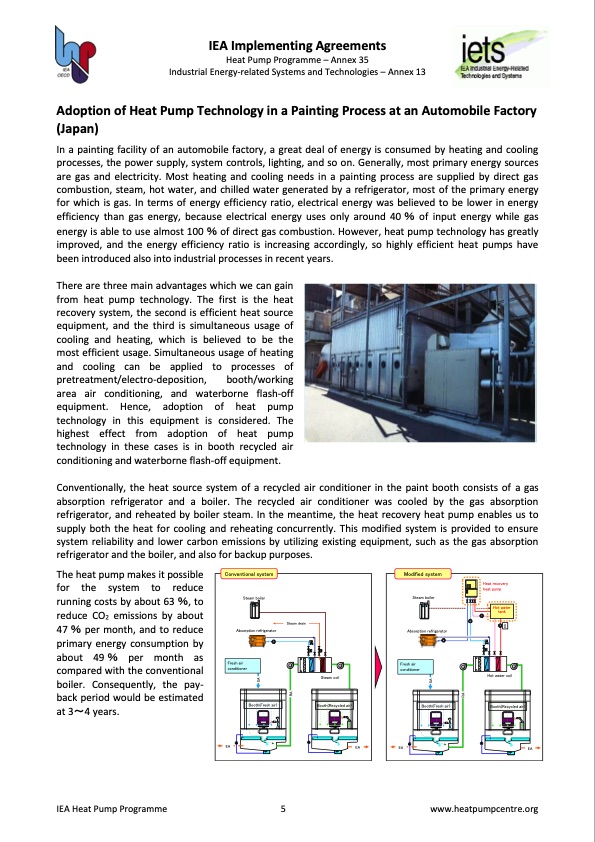

IEA Implementing Agreements Heat Pump Programme – Annex 35 Industrial Energy-related Systems and Technologies – Annex 13 Adoption of Heat Pump Technology in a Painting Process at an Automobile Factory (Japan) In a painting facility of an automobile factory, a great deal of energy is consumed by heating and cooling processes, the power supply, system controls, lighting, and so on. Generally, most primary energy sources are gas and electricity. Most heating and cooling needs in a painting process are supplied by direct gas combustion, steam, hot water, and chilled water generated by a refrigerator, most of the primary energy for which is gas. In terms of energy efficiency ratio, electrical energy was believed to be lower in energy efficiency than gas energy, because electrical energy uses only around 40 % of input energy while gas energy is able to use almost 100 % of direct gas combustion. However, heat pump technology has greatly improved, and the energy efficiency ratio is increasing accordingly, so highly efficient heat pumps have been introduced also into industrial processes in recent years. There are three main advantages which we can gain from heat pump technology. The first is the heat recovery system, the second is efficient heat source equipment, and the third is simultaneous usage of cooling and heating, which is believed to be the most efficient usage. Simultaneous usage of heating and cooling can be applied to processes of pretreatment/electro-deposition, booth/working area air conditioning, and waterborne flash-off equipment. Hence, adoption of heat pump technology in this equipment is considered. The highest effect from adoption of heat pump technology in these cases is in booth recycled air conditioning and waterborne flash-off equipment. Conventionally, the heat source system of a recycled air conditioner in the paint booth consists of a gas absorption refrigerator and a boiler. The recycled air conditioner was cooled by the gas absorption refrigerator, and reheated by boiler steam. In the meantime, the heat recovery heat pump enables us to supply both the heat for cooling and reheating concurrently. This modified system is provided to ensure system reliability and lower carbon emissions by utilizing existing equipment, such as the gas absorption refrigerator and the boiler, and also for backup purposes. The heat pump makes it possible for the system to reduce running costs by about 63 %, to reduce CO2 emissions by about 47 % per month, and to reduce primary energy consumption by about 49 % per month as compared with the conventional boiler. Consequently, the pay- back period would be estimated at 3~4 years. Conventional system Modified system Steam boiler Absorption refrigerator Steam boiler Absorption refrigerator Steam drain Heat recovery heat pump Hot water tank Hot water coil Steam coil Booth(Fresh air) Booth(Recycled air) Booth(Fresh air) Booth(Recycled air) IEA Heat Pump Programme 5 www.heatpumpcentre.org Fresh air conditioner EA EA EA EA Fresh air conditioner RA RA SA SA INVPDF Image | Industrial Heat Pumps

PDF Search Title:

Industrial Heat PumpsOriginal File Name Searched:

annex-xiii-part-a.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |