PDF Publication Title:

Text from PDF Page: 022

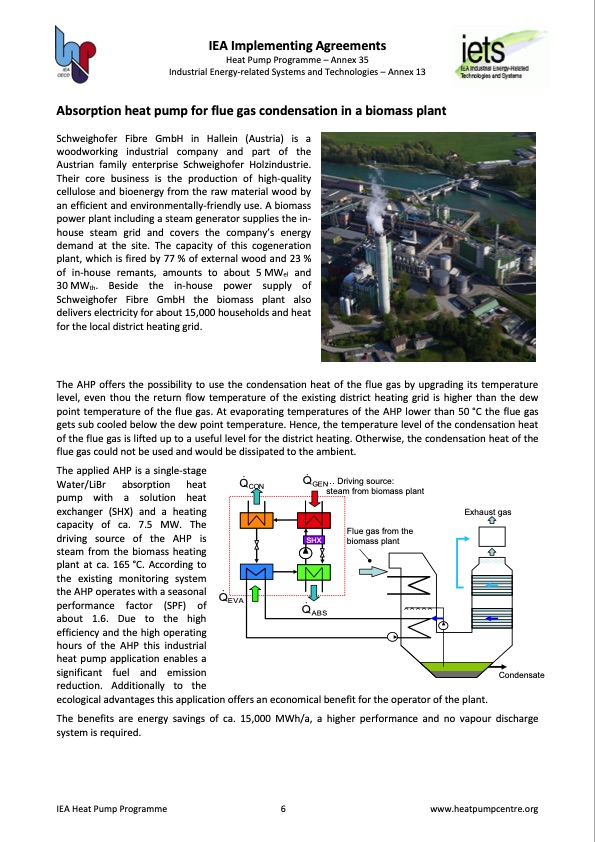

IEA Implementing Agreements Heat Pump Programme – Annex 35 Industrial Energy-related Systems and Technologies – Annex 13 Absorption heat pump for flue gas condensation in a biomass plant Schweighofer Fibre GmbH in Hallein (Austria) is a woodworking industrial company and part of the Austrian family enterprise Schweighofer Holzindustrie. Their core business is the production of high-quality cellulose and bioenergy from the raw material wood by an efficient and environmentally-friendly use. A biomass power plant including a steam generator supplies the in- house steam grid and covers the company’s energy demand at the site. The capacity of this cogeneration plant, which is fired by 77 % of external wood and 23 % of in-house remants, amounts to about 5 MWel and 30MWth. Beside the in-house power supply of Schweighofer Fibre GmbH the biomass plant also delivers electricity for about 15,000 households and heat for the local district heating grid. The AHP offers the possibility to use the condensation heat of the flue gas by upgrading its temperature level, even thou the return flow temperature of the existing district heating grid is higher than the dew point temperature of the flue gas. At evaporating temperatures of the AHP lower than 50 °C the flue gas gets sub cooled below the dew point temperature. Hence, the temperature level of the condensation heat of the flue gas is lifted up to a useful level for the district heating. Otherwise, the condensation heat of the flue gas could not be used and would be dissipated to the ambient. The applied AHP is a single-stage Water/LiBr absorption heat pump with a solution heat exchanger (SHX) and a heating capacity of ca. 7.5 MW. The driving source of the AHP is steam from the biomass heating plant at ca. 165 °C. According to the existing monitoring system the AHP operates with a seasonal performance factor (SPF) of about 1.6. Due to the high efficiency and the high operating hours of the AHP this industrial heat pump application enables a significant fuel and emission reduction. Additionally to the ecological advantages this application offers an economical benefit for the operator of the plant. The benefits are energy savings of ca. 15,000 MWh/a, a higher performance and no vapour discharge system is required. QCON Q E V A steam from biomass plant Q ... Driving source: GE N Flue gas from the SHX biomass plant Q A B S Exhaust gas Condensate IEA Heat Pump Programme 6 www.heatpumpcentre.orgPDF Image | Industrial Heat Pumps

PDF Search Title:

Industrial Heat PumpsOriginal File Name Searched:

annex-xiii-part-a.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |