PDF Publication Title:

Text from PDF Page: 032

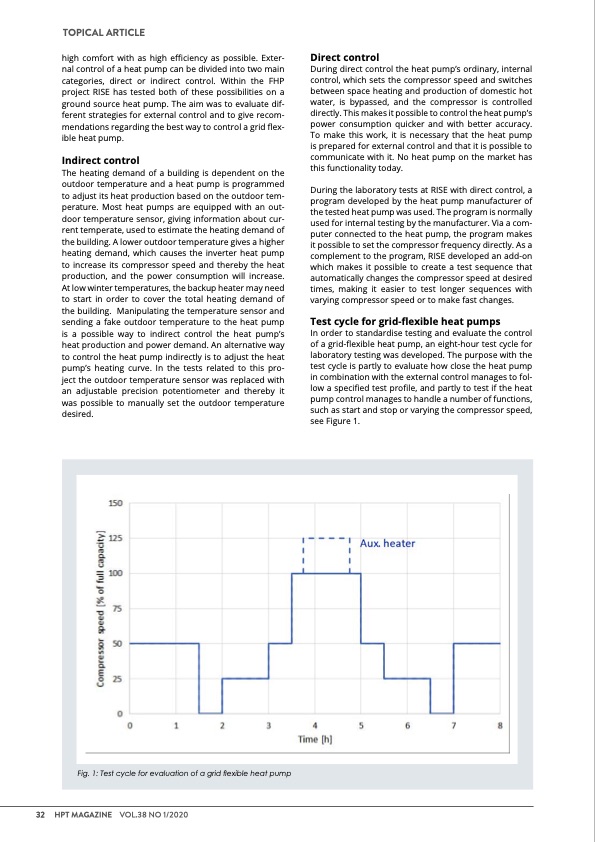

TOPICAL ARTICLE high comfort with as high efficiency as possible. Exter- nal control of a heat pump can be divided into two main categories, direct or indirect control. Within the FHP project RISE has tested both of these possibilities on a ground source heat pump. The aim was to evaluate dif- ferent strategies for external control and to give recom- mendations regarding the best way to control a grid flex- ible heat pump. Indirect control The heating demand of a building is dependent on the outdoor temperature and a heat pump is programmed to adjust its heat production based on the outdoor tem- perature. Most heat pumps are equipped with an out- door temperature sensor, giving information about cur- rent temperate, used to estimate the heating demand of the building. A lower outdoor temperature gives a higher heating demand, which causes the inverter heat pump to increase its compressor speed and thereby the heat production, and the power consumption will increase. At low winter temperatures, the backup heater may need to start in order to cover the total heating demand of the building. Manipulating the temperature sensor and sending a fake outdoor temperature to the heat pump is a possible way to indirect control the heat pump’s heat production and power demand. An alternative way to control the heat pump indirectly is to adjust the heat pump’s heating curve. In the tests related to this pro- ject the outdoor temperature sensor was replaced with an adjustable precision potentiometer and thereby it was possible to manually set the outdoor temperature desired. Direct control During direct control the heat pump’s ordinary, internal control, which sets the compressor speed and switches between space heating and production of domestic hot water, is bypassed, and the compressor is controlled directly. This makes it possible to control the heat pump’s power consumption quicker and with better accuracy. To make this work, it is necessary that the heat pump is prepared for external control and that it is possible to communicate with it. No heat pump on the market has this functionality today. During the laboratory tests at RISE with direct control, a program developed by the heat pump manufacturer of the tested heat pump was used. The program is normally used for internal testing by the manufacturer. Via a com- puter connected to the heat pump, the program makes it possible to set the compressor frequency directly. As a complement to the program, RISE developed an add-on which makes it possible to create a test sequence that automatically changes the compressor speed at desired times, making it easier to test longer sequences with varying compressor speed or to make fast changes. Test cycle for grid-flexible heat pumps In order to standardise testing and evaluate the control of a grid-flexible heat pump, an eight-hour test cycle for laboratory testing was developed. The purpose with the test cycle is partly to evaluate how close the heat pump in combination with the external control manages to fol- low a specified test profile, and partly to test if the heat pump control manages to handle a number of functions, such as start and stop or varying the compressor speed, see Figure 1. Fig. 1: Test cycle for evaluation of a grid flexible heat pump 32 HPT MAGAZINE VOL.38 NO 1/2020PDF Image | Integration of Heat Pumps into the Future Energy

PDF Search Title:

Integration of Heat Pumps into the Future EnergyOriginal File Name Searched:

HPT-Magazine_no1_2020.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |