PDF Publication Title:

Text from PDF Page: 033

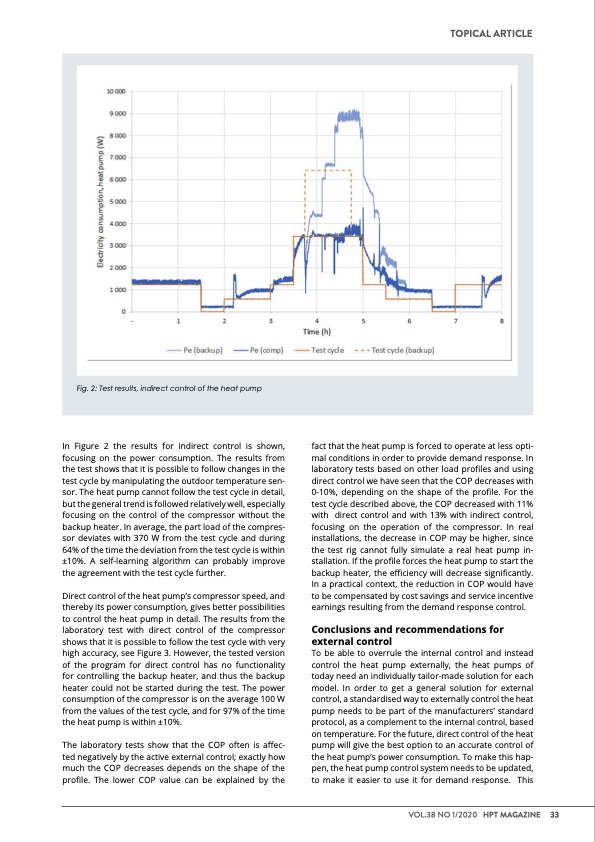

In Figure 2 the results for indirect control is shown, focusing on the power consumption. The results from the test shows that it is possible to follow changes in the test cycle by manipulating the outdoor temperature sen- sor. The heat pump cannot follow the test cycle in detail, but the general trend is followed relatively well, especially focusing on the control of the compressor without the backup heater. In average, the part load of the compres- sor deviates with 370 W from the test cycle and during 64% of the time the deviation from the test cycle is within ±10%. A self-learning algorithm can probably improve the agreement with the test cycle further. Direct control of the heat pump’s compressor speed, and thereby its power consumption, gives better possibilities to control the heat pump in detail. The results from the laboratory test with direct control of the compressor shows that it is possible to follow the test cycle with very high accuracy, see Figure 3. However, the tested version of the program for direct control has no functionality for controlling the backup heater, and thus the backup heater could not be started during the test. The power consumption of the compressor is on the average 100 W from the values of the test cycle, and for 97% of the time the heat pump is within ±10%. The laboratory tests show that the COP often is affec- ted negatively by the active external control; exactly how much the COP decreases depends on the shape of the profile. The lower COP value can be explained by the fact that the heat pump is forced to operate at less opti- mal conditions in order to provide demand response. In laboratory tests based on other load profiles and using direct control we have seen that the COP decreases with 0-10%, depending on the shape of the profile. For the test cycle described above, the COP decreased with 11% with direct control and with 13% with indirect control, focusing on the operation of the compressor. In real installations, the decrease in COP may be higher, since the test rig cannot fully simulate a real heat pump in- stallation. If the profile forces the heat pump to start the backup heater, the efficiency will decrease significantly. In a practical context, the reduction in COP would have to be compensated by cost savings and service incentive earnings resulting from the demand response control. Conclusions and recommendations for external control To be able to overrule the internal control and instead control the heat pump externally, the heat pumps of today need an individually tailor-made solution for each model. In order to get a general solution for external control, a standardised way to externally control the heat pump needs to be part of the manufacturers’ standard protocol, as a complement to the internal control, based on temperature. For the future, direct control of the heat pump will give the best option to an accurate control of the heat pump’s power consumption. To make this hap- pen, the heat pump control system needs to be updated, to make it easier to use it for demand response. This TOPICAL ARTICLE Fig. 2: Test results, indirect control of the heat pump VOL.38 NO 1/2020 HPT MAGAZINE 33PDF Image | Integration of Heat Pumps into the Future Energy

PDF Search Title:

Integration of Heat Pumps into the Future EnergyOriginal File Name Searched:

HPT-Magazine_no1_2020.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |