PDF Publication Title:

Text from PDF Page: 002

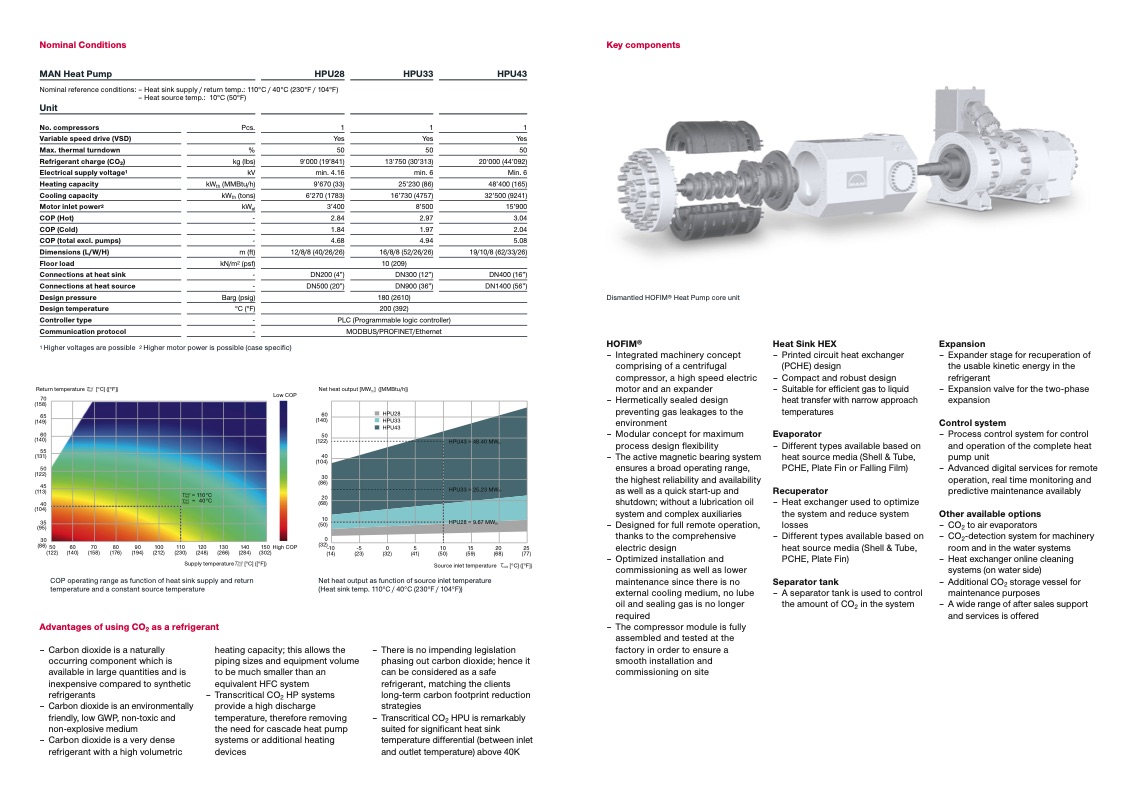

Nominal Conditions MAN Heat Pump HPU28 HPU33 HPU43 Nominal reference conditions: – Heat sink supply / return temp.: 110°C / 40°C (230°F / 104°F) Key components Unit No. compressors Variable speed drive (VSD) Max. thermal turndown Refrigerant charge (CO2) Electrical supply voltage1 Heating capacity Cooling capacity Motor inlet power2 COP (Hot) COP (Cold) COP (total excl. pumps) Dimensions (L/W/H) Floor load Connections at heat sink Connections at heat source Design pressure Design temperature Controller type Communication protocol – Heat source temp.: 10°C (50°F) Pcs. % kg (lbs) kV kWth (MMBtu/h) kWth (tons) kWel - - - m (ft) kN/m2 (psf) - - Barg (psig) °C (°F) - - 111 Yes Yes Yes 505050 9'000 (19’841) min. 4.16 9’670 (33) 6’270 (1783) 13'750 (30’313) min. 6 25’230 (86) 16’730 (4757) 20'000 (44’092) Min. 6 48’400 (165) 32’500 (9241) 3’400 8’500 15’900 2.84 2.97 3.04 1.84 1.97 2.04 4.68 4.94 5.08 12/8/8 (40/26/26) DN200 (4”) DN500 (20”) 16/8/8 (52/26/26) 10 (209) DN300 (12”) DN900 (36”) 180 (2610) 19/10/8 (62/33/26) DN400 (16”) DN1400 (56”) Dismantled HOFIM® Heat Pump core unit HOFIM® – Integrated machinery concept comprising of a centrifugal compressor, a high speed electric motor and an expander Hermetically sealed design preventing gas leakages to the environment 1 Higher voltages are possible 2 Higher motor power is possible (case specific) 200 (392) PLC (Programmable logic controller) MODBUS/PROFINET/Ethernet Net heat output [MWth ] ([MMBtu/h]) 60 (140) 50 (122) 40 (104) 30 (86) 20 (68) 10 (50) Heat Sink HEX – Printed circuit heat exchanger (PCHE) design – Compact and robust design – Suitable for efficient gas to liquid heat transfer with narrow approach temperatures Evaporator – Different types available based on heat source media (Shell & Tube, PCHE, Plate Fin or Falling Film) Recuperator – Heat exchanger used to optimize the system and reduce system losses Expansion – Expander stage for recuperation of the usable kinetic energy in the refrigerant – Expansion valve for the two-phase expansion Control system – Process control system for control and operation of the complete heat pump unit – Advanced digital services for remote operation, real time monitoring and predictive maintenance availably Other available options – CO to air evaporators – CO2-detection system for machinery Return temperature Throett 70 65 (149) 60 (140) 55 (131) 50 (122) 45 (113) 40 (104) 35 (95) [°C] ([°F]) Low COP – – – – (158) HPU28 HPU33 HPU43 HPU43 = 48.40 MWth HPU33 = 25.23 MWth 9.67 MWth sup Thot = 11 ret = 4 Thot 0°C 0°C HPU28 = Modular concept for maximum process design flexibility The active magnetic bearing system ensures a broad operating range, the highest reliability and availability as well as a quick start-up and shutdown; without a lubrication oil system and complex auxiliaries Designed for full remote operation, thanks to the comprehensive 300 2 (86) 50 60 70 80 90 100 110 120 130 140 150 High COP (122) (140) (158) (176) (194) (212) (230) (248) (266) (284) (302) sup Supply temperature Thot [°C] ([°F]) COP operating range as function of heat sink supply and return temperature and a constant source temperature Advantages of using CO2 as a refrigerant (32)-10 -5 0 5 10 15 20 25 (14) (23) (32) (41) (50) (59) (68) (77) Source inlet temperature Tcold [°C] ([°F]) Net heat output as function of source inlet temperature (Heat sink temp. 110°C / 40°C (230°F / 104°F)) electric design – Optimized installation and room and in the water systems – Heat exchanger online cleaning systems (on water side) – Additional CO2 storage vessel for maintenance purposes – A wide range of after sales support and services is offered – Carbon dioxide is a naturally occurring component which is available in large quantities and is inexpensive compared to synthetic refrigerants – Carbon dioxide is an environmentally friendly, low GWP, non-toxic and non-explosive medium – Carbon dioxide is a very dense refrigerant with a high volumetric heating capacity; this allows the piping sizes and equipment volume to be much smaller than an equivalent HFC system – Transcritical CO2 HP systems provide a high discharge temperature, therefore removing the need for cascade heat pump systems or additional heating devices – There is no impending legislation phasing out carbon dioxide; hence it can be considered as a safe refrigerant, matching the clients long-term carbon footprint reduction strategies – Transcritical CO2 HPU is remarkably suited for significant heat sink temperature differential (between inlet and outlet temperature) above 40K commissioning as well as lower maintenance since there is no external cooling medium, no lube oil and sealing gas is no longer required – The compressor module is fully assembled and tested at the factory in order to ensure a smooth installation and commissioning on site – Different types available based on heat source media (Shell & Tube, PCHE, Plate Fin) Separator tank – A separator tank is used to control the amount of CO2 in the systemPDF Image | MAN Heat Pump CO2

PDF Search Title:

MAN Heat Pump CO2Original File Name Searched:

man-heat-pump-hpu-eng.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |