PDF Publication Title:

Text from PDF Page: 004

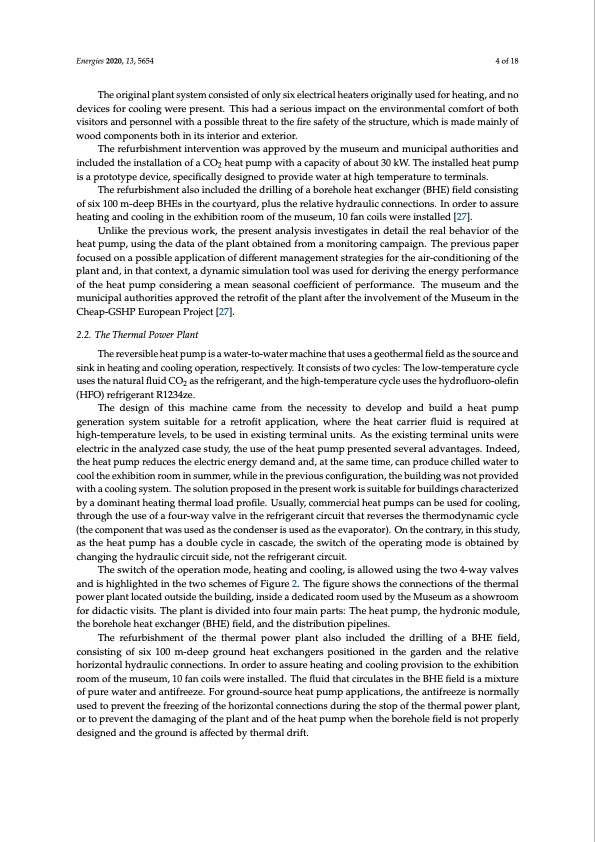

Energies 2020, 13, 5654 4 of 18 The original plant system consisted of only six electrical heaters originally used for heating, and no devices for cooling were present. This had a serious impact on the environmental comfort of both visitors and personnel with a possible threat to the fire safety of the structure, which is made mainly of wood components both in its interior and exterior. The refurbishment intervention was approved by the museum and municipal authorities and included the installation of a CO2 heat pump with a capacity of about 30 kW. The installed heat pump is a prototype device, specifically designed to provide water at high temperature to terminals. The refurbishment also included the drilling of a borehole heat exchanger (BHE) field consisting of six 100 m-deep BHEs in the courtyard, plus the relative hydraulic connections. In order to assure heating and cooling in the exhibition room of the museum, 10 fan coils were installed [27]. Unlike the previous work, the present analysis investigates in detail the real behavior of the heat pump, using the data of the plant obtained from a monitoring campaign. The previous paper focused on a possible application of different management strategies for the air-conditioning of the plant and, in that context, a dynamic simulation tool was used for deriving the energy performance of the heat pump considering a mean seasonal coefficient of performance. The museum and the municipal authorities approved the retrofit of the plant after the involvement of the Museum in the Cheap-GSHP European Project [27]. 2.2. The Thermal Power Plant The reversible heat pump is a water-to-water machine that uses a geothermal field as the source and sink in heating and cooling operation, respectively. It consists of two cycles: The low-temperature cycle uses the natural fluid CO2 as the refrigerant, and the high-temperature cycle uses the hydrofluoro-olefin (HFO) refrigerant R1234ze. The design of this machine came from the necessity to develop and build a heat pump generation system suitable for a retrofit application, where the heat carrier fluid is required at high-temperature levels, to be used in existing terminal units. As the existing terminal units were electric in the analyzed case study, the use of the heat pump presented several advantages. Indeed, the heat pump reduces the electric energy demand and, at the same time, can produce chilled water to cool the exhibition room in summer, while in the previous configuration, the building was not provided with a cooling system. The solution proposed in the present work is suitable for buildings characterized by a dominant heating thermal load profile. Usually, commercial heat pumps can be used for cooling, through the use of a four-way valve in the refrigerant circuit that reverses the thermodynamic cycle (the component that was used as the condenser is used as the evaporator). On the contrary, in this study, as the heat pump has a double cycle in cascade, the switch of the operating mode is obtained by changing the hydraulic circuit side, not the refrigerant circuit. The switch of the operation mode, heating and cooling, is allowed using the two 4-way valves and is highlighted in the two schemes of Figure 2. The figure shows the connections of the thermal power plant located outside the building, inside a dedicated room used by the Museum as a showroom for didactic visits. The plant is divided into four main parts: The heat pump, the hydronic module, the borehole heat exchanger (BHE) field, and the distribution pipelines. The refurbishment of the thermal power plant also included the drilling of a BHE field, consisting of six 100 m-deep ground heat exchangers positioned in the garden and the relative horizontal hydraulic connections. In order to assure heating and cooling provision to the exhibition room of the museum, 10 fan coils were installed. The fluid that circulates in the BHE field is a mixture of pure water and antifreeze. For ground-source heat pump applications, the antifreeze is normally used to prevent the freezing of the horizontal connections during the stop of the thermal power plant, or to prevent the damaging of the plant and of the heat pump when the borehole field is not properly designed and the ground is affected by thermal drift.PDF Image | Novel Ground-Source Heat Pump with R744

PDF Search Title:

Novel Ground-Source Heat Pump with R744Original File Name Searched:

energies-13-05654.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |