PDF Publication Title:

Text from PDF Page: 008

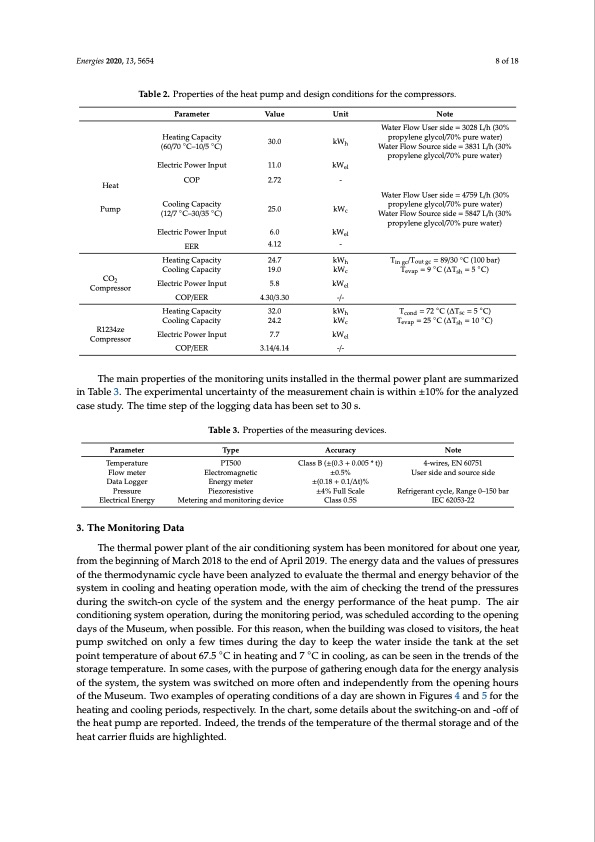

Energies 2020, 13, 5654 8 of 18 Table 2. Properties of the heat pump and design conditions for the compressors. Heat Pump CO2 Compressor R1234ze Compressor Parameter Heating Capacity (60/70 ◦C–10/5 ◦C) Electric Power Input COP Cooling Capacity (12/7 ◦C–30/35 ◦C) Electric Power Input EER Heating Capacity Cooling Capacity Electric Power Input COP/EER Heating Capacity Cooling Capacity Electric Power Input COP/EER Value Unit Note Water Flow User side = 3028 L/h (30% 30.0 kW propylene glycol/70% pure water) h Water Flow Source side = 3831 L/h (30% propylene glycol/70% pure water) 11.0 kWel 2.72 - Water Flow User side = 4759 L/h (30% 25.0 kWc propylene glycol/70% pure water) Water Flow Source side = 5847 L/h (30% propylene glycol/70% pure water) 6.0 kWel 4.12 - 24.7 kWh Tin gc/Tout gc = 89/30 ◦C (100 bar) 19.0 kWc Tevap =9◦C(∆Tsh =5◦C) 5.8 kWel 4.30/3.30 -/- 32.0 kWh Tcond = 72 ◦C (∆Tsc = 5 ◦C) 24.2 kWc Tevap = 25 ◦C (∆Tsh = 10 ◦C) 7.7 kWel 3.14/4.14 -/- The main properties of the monitoring units installed in the thermal power plant are summarized in Table 3. The experimental uncertainty of the measurement chain is within ±10% for the analyzed case study. The time step of the logging data has been set to 30 s. Table 3. Properties of the measuring devices. Parameter Temperature Flow meter Data Logger Pressure Electrical Energy Type PT500 Electromagnetic Energy meter Piezoresistive Metering and monitoring device Accuracy Class B (±(0.3 + 0.005 * t)) ±0.5% ±(0.18 + 0.1/∆t)% ±4% Full Scale Class 0.5S Note 4-wires, EN 60751 User side and source side Refrigerant cycle, Range 0–150 bar IEC 62053-22 3. The Monitoring Data The thermal power plant of the air conditioning system has been monitored for about one year, from the beginning of March 2018 to the end of April 2019. The energy data and the values of pressures of the thermodynamic cycle have been analyzed to evaluate the thermal and energy behavior of the system in cooling and heating operation mode, with the aim of checking the trend of the pressures during the switch-on cycle of the system and the energy performance of the heat pump. The air conditioning system operation, during the monitoring period, was scheduled according to the opening days of the Museum, when possible. For this reason, when the building was closed to visitors, the heat pump switched on only a few times during the day to keep the water inside the tank at the set point temperature of about 67.5 ◦C in heating and 7 ◦C in cooling, as can be seen in the trends of the storage temperature. In some cases, with the purpose of gathering enough data for the energy analysis of the system, the system was switched on more often and independently from the opening hours of the Museum. Two examples of operating conditions of a day are shown in Figures 4 and 5 for the heating and cooling periods, respectively. In the chart, some details about the switching-on and -off of the heat pump are reported. Indeed, the trends of the temperature of the thermal storage and of the heat carrier fluids are highlighted.PDF Image | Novel Ground-Source Heat Pump with R744

PDF Search Title:

Novel Ground-Source Heat Pump with R744Original File Name Searched:

energies-13-05654.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |