PDF Publication Title:

Text from PDF Page: 011

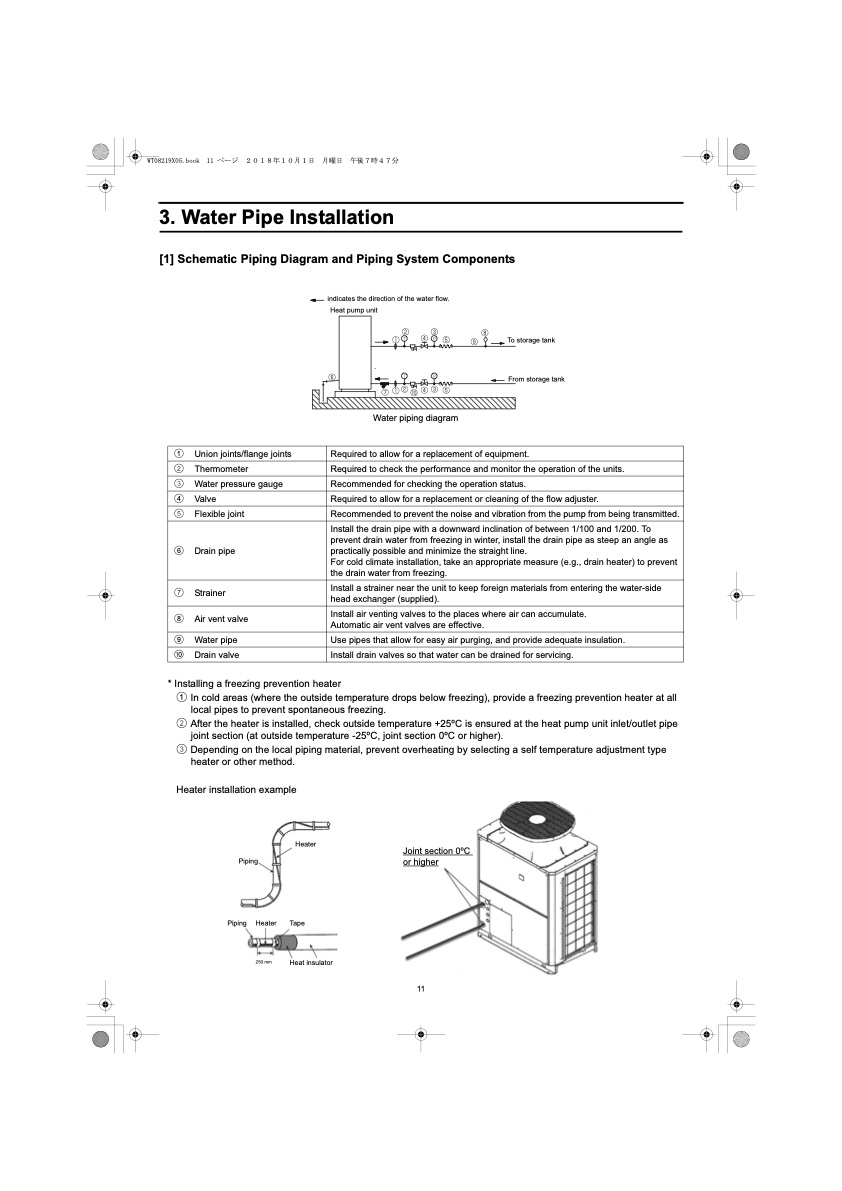

3. Water Pipe Installation [1] Schematic Piping Diagram and Piping System Components indicates the direction of the water flow. Heat pump unit 6 2438 1 T P 5 9 TP 71210435 Water piping diagram To storage tank From storage tank 1 Union joints/flange joints Required to allow for a replacement of equipment. 2 Thermometer Required to check the performance and monitor the operation of the units. 3 Water pressure gauge Recommended for checking the operation status. 4 Valve Required to allow for a replacement or cleaning of the flow adjuster. 5 Flexible joint Recommended to prevent the noise and vibration from the pump from being transmitted. 6 Drain pipe Install the drain pipe with a downward inclination of between 1/100 and 1/200. To prevent drain water from freezing in winter, install the drain pipe as steep an angle as practically possible and minimize the straight line. For cold climate installation, take an appropriate measure (e.g., drain heater) to prevent the drain water from freezing. 7 Strainer Install a strainer near the unit to keep foreign materials from entering the water-side head exchanger (supplied). 8 Air vent valve Install air venting valves to the places where air can accumulate. Automatic air vent valves are effective. 9 Water pipe Use pipes that allow for easy air purging, and provide adequate insulation. 0 Drain valve Install drain valves so that water can be drained for servicing. * Installing a freezing prevention heater 1 In cold areas (where the outside temperature drops below freezing), provide a freezing prevention heater at all local pipes to prevent spontaneous freezing. 2 After the heater is installed, check outside temperature +25oC is ensured at the heat pump unit inlet/outlet pipe joint section (at outside temperature -25oC, joint section 0oC or higher). 3 Depending on the local piping material, prevent overheating by selecting a self temperature adjustment type heater or other method. Heater installation example Heater Piping Piping Heater Tape Joint section 0oC or higher 250 mm Heat insulator 11PDF Image | QAHV-N560YA-HPB

PDF Search Title:

QAHV-N560YA-HPBOriginal File Name Searched:

IBIM_WT08219X05_QAHV_N560YA_HPB_ML.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |