PDF Publication Title:

Text from PDF Page: 014

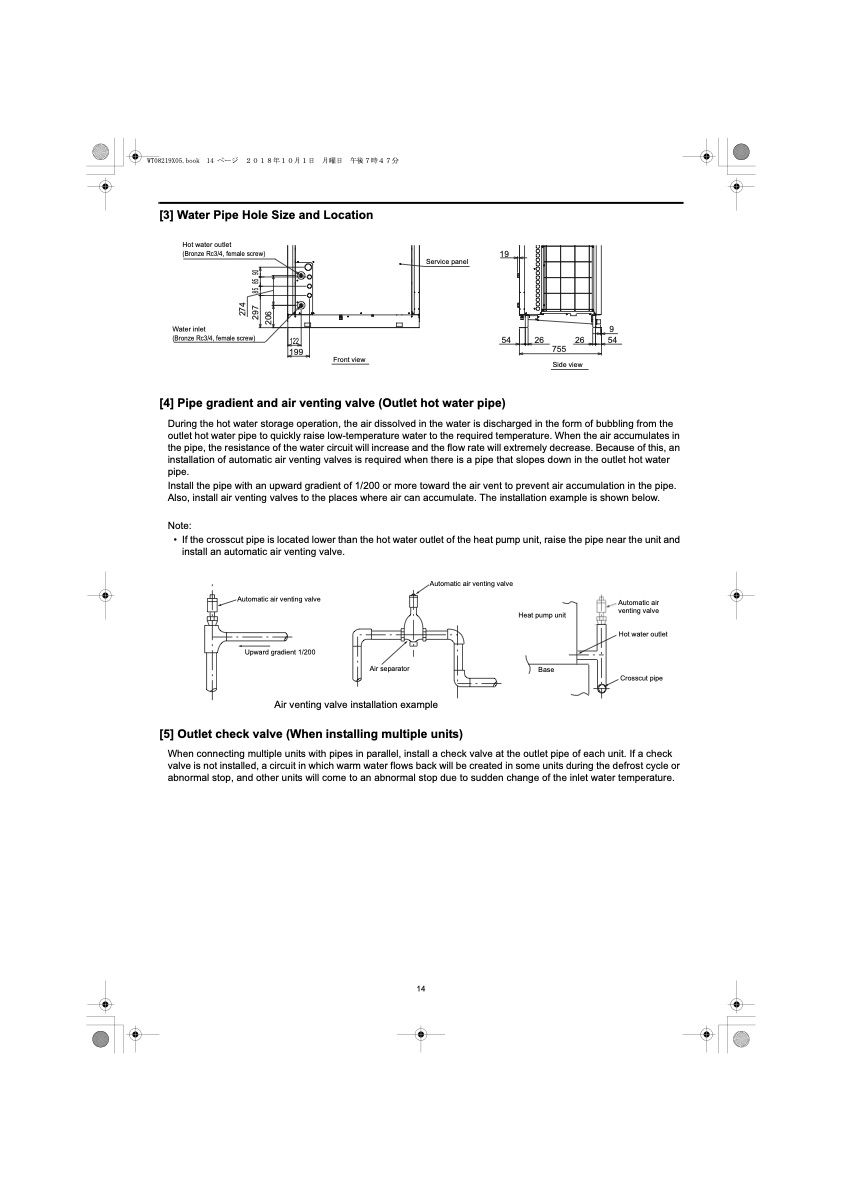

[3] Water Pipe Hole Size and Location Hot water outlet (Bronze Rc3/4, female screw) Water inlet (Bronze Rc3/4, female screw) Service panel 19 122 199 54 26 9 26 54 Side view [4] Pipe gradient and air venting valve (Outlet hot water pipe) Front view 755 During the hot water storage operation, the air dissolved in the water is discharged in the form of bubbling from the outlet hot water pipe to quickly raise low-temperature water to the required temperature. When the air accumulates in the pipe, the resistance of the water circuit will increase and the flow rate will extremely decrease. Because of this, an installation of automatic air venting valves is required when there is a pipe that slopes down in the outlet hot water pipe. Install the pipe with an upward gradient of 1/200 or more toward the air vent to prevent air accumulation in the pipe. Also, install air venting valves to the places where air can accumulate. The installation example is shown below. Note: • If the crosscut pipe is located lower than the hot water outlet of the heat pump unit, raise the pipe near the unit and install an automatic air venting valve. [5] Outlet check valve (When installing multiple units) When connecting multiple units with pipes in parallel, install a check valve at the outlet pipe of each unit. If a check valve is not installed, a circuit in which warm water flows back will be created in some units during the defrost cycle or abnormal stop, and other units will come to an abnormal stop due to sudden change of the inlet water temperature. Automatic air venting valve Automatic air venting valve Upward gradient 1/200 Heat pump unit Automatic air venting valve Hot water outlet Crosscut pipe Air separator Base Air venting valve installation example 14 274 297 85 85 90 206PDF Image | QAHV-N560YA-HPB

PDF Search Title:

QAHV-N560YA-HPBOriginal File Name Searched:

IBIM_WT08219X05_QAHV_N560YA_HPB_ML.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |