PDF Publication Title:

Text from PDF Page: 015

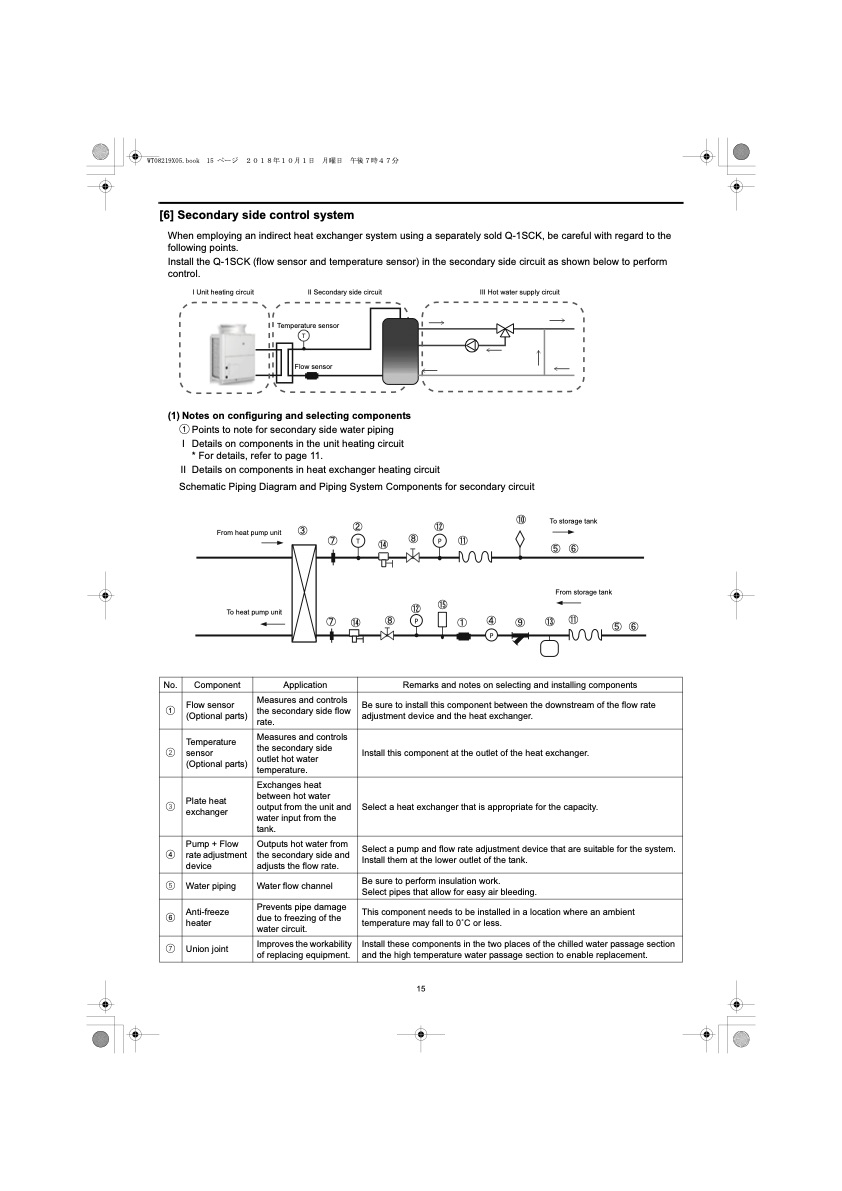

[6] Secondary side control system When employing an indirect heat exchanger system using a separately sold Q-1SCK, be careful with regard to the following points. Install the Q-1SCK (flow sensor and temperature sensor) in the secondary side circuit as shown below to perform control. I Unit heating circuit II Secondary side circuit III Hot water supply circuit Temperature sensor T (1) Notes on configuring and selecting components 1 Points to note for secondary side water piping I Details on components in the unit heating circuit * For details, refer to page 11. II Details on components in heat exchanger heating circuit Schematic Piping Diagram and Piping System Components for secondary circuit Flow sensor From heat pump unit To heat pump unit � �� �T��P� � � To storage tank �� From storage tank � ���P ����� P �� No. Component Application Remarks and notes on selecting and installing components 1 Flow sensor (Optional parts) Measures and controls the secondary side flow rate. Be sure to install this component between the downstream of the flow rate adjustment device and the heat exchanger. 2 Temperature sensor (Optional parts) Measures and controls the secondary side outlet hot water temperature. Install this component at the outlet of the heat exchanger. 3 Plate heat exchanger Exchanges heat between hot water output from the unit and water input from the tank. Select a heat exchanger that is appropriate for the capacity. 4 Pump + Flow rate adjustment device Outputs hot water from the secondary side and adjusts the flow rate. Select a pump and flow rate adjustment device that are suitable for the system. Install them at the lower outlet of the tank. 5 Water piping Water flow channel Be sure to perform insulation work. Select pipes that allow for easy air bleeding. 6 Anti-freeze heater Prevents pipe damage due to freezing of the water circuit. This component needs to be installed in a location where an ambient temperature may fall to 0 ̊C or less. 7 Union joint Improves the workability of replacing equipment. Install these components in the two places of the chilled water passage section and the high temperature water passage section to enable replacement. 15PDF Image | QAHV-N560YA-HPB

PDF Search Title:

QAHV-N560YA-HPBOriginal File Name Searched:

IBIM_WT08219X05_QAHV_N560YA_HPB_ML.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |