PDF Publication Title:

Text from PDF Page: 009

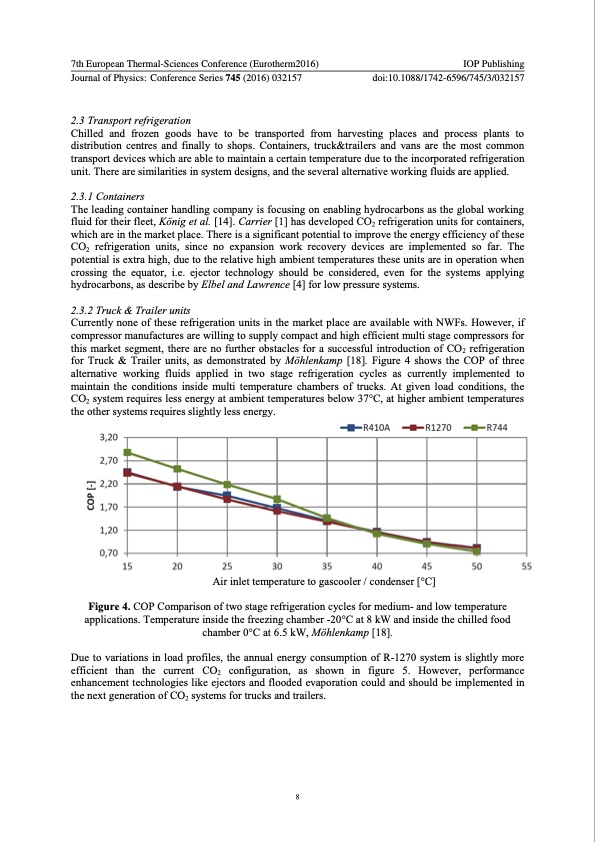

7th European Thermal-Sciences Conference (Eurotherm2016) IOP Publishing Journal of Physics: Conference Series 745 (2016) 032157 doi:10.1088/1742-6596/745/3/032157 2.3 Transport refrigeration Chilled and frozen goods have to be transported from harvesting places and process plants to distribution centres and finally to shops. Containers, truck&trailers and vans are the most common transport devices which are able to maintain a certain temperature due to the incorporated refrigeration unit. There are similarities in system designs, and the several alternative working fluids are applied. 2.3.1 Containers The leading container handling company is focusing on enabling hydrocarbons as the global working fluid for their fleet, König et al. [14]. Carrier [1] has developed CO2 refrigeration units for containers, which are in the market place. There is a significant potential to improve the energy efficiency of these CO2 refrigeration units, since no expansion work recovery devices are implemented so far. The potential is extra high, due to the relative high ambient temperatures these units are in operation when crossing the equator, i.e. ejector technology should be considered, even for the systems applying hydrocarbons, as describe by Elbel and Lawrence [4] for low pressure systems. 2.3.2 Truck & Trailer units Currently none of these refrigeration units in the market place are available with NWFs. However, if compressor manufactures are willing to supply compact and high efficient multi stage compressors for this market segment, there are no further obstacles for a successful introduction of CO2 refrigeration for Truck & Trailer units, as demonstrated by Möhlenkamp [18]. Figure 4 shows the COP of three alternative working fluids applied in two stage refrigeration cycles as currently implemented to maintain the conditions inside multi temperature chambers of trucks. At given load conditions, the CO2 system requires less energy at ambient temperatures below 37°C, at higher ambient temperatures the other systems requires slightly less energy. Air inlet temperature to gascooler / condenser [°C] Figure 4. COP Comparison of two stage refrigeration cycles for medium- and low temperature applications. Temperature inside the freezing chamber -20°C at 8 kW and inside the chilled food chamber 0°C at 6.5 kW, Möhlenkamp [18]. Due to variations in load profiles, the annual energy consumption of R-1270 system is slightly more efficient than the current CO2 configuration, as shown in figure 5. However, performance enhancement technologies like ejectors and flooded evaporation could and should be implemented in the next generation of CO2 systems for trucks and trailers. 8PDF Image | R744 ejector technology

PDF Search Title:

R744 ejector technologyOriginal File Name Searched:

Hafner_2016-745_032157.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |