PDF Publication Title:

Text from PDF Page: 010

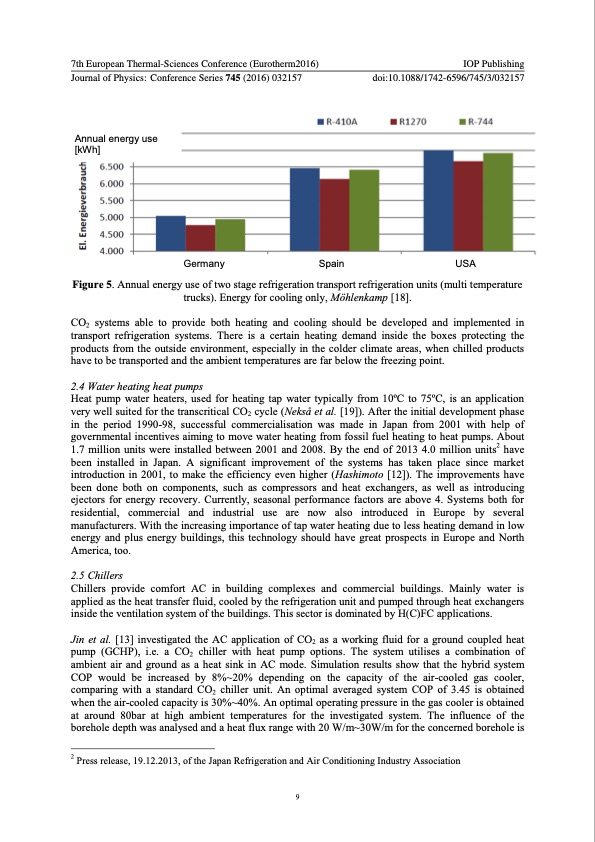

7th European Thermal-Sciences Conference (Eurotherm2016) Journal of Physics: Conference Series 745 (2016) 032157 IOP Publishing doi:10.1088/1742-6596/745/3/032157 Annual energy use [kWh] Germany Spain USA Figure 5. Annual energy use of two stage refrigeration transport refrigeration units (multi temperature trucks). Energy for cooling only, Möhlenkamp [18]. CO2 systems able to provide both heating and cooling should be developed and implemented in transport refrigeration systems. There is a certain heating demand inside the boxes protecting the products from the outside environment, especially in the colder climate areas, when chilled products have to be transported and the ambient temperatures are far below the freezing point. 2.4 Water heating heat pumps Heat pump water heaters, used for heating tap water typically from 10oC to 75oC, is an application very well suited for the transcritical CO2 cycle (Nekså et al. [19]). After the initial development phase in the period 1990-98, successful commercialisation was made in Japan from 2001 with help of governmental incentives aiming to move water heating from fossil fuel heating to heat pumps. About 1.7 million units were installed between 2001 and 2008. By the end of 2013 4.0 million units2 have been installed in Japan. A significant improvement of the systems has taken place since market introduction in 2001, to make the efficiency even higher (Hashimoto [12]). The improvements have been done both on components, such as compressors and heat exchangers, as well as introducing ejectors for energy recovery. Currently, seasonal performance factors are above 4. Systems both for residential, commercial and industrial use are now also introduced in Europe by several manufacturers. With the increasing importance of tap water heating due to less heating demand in low energy and plus energy buildings, this technology should have great prospects in Europe and North America, too. 2.5 Chillers Chillers provide comfort AC in building complexes and commercial buildings. Mainly water is applied as the heat transfer fluid, cooled by the refrigeration unit and pumped through heat exchangers inside the ventilation system of the buildings. This sector is dominated by H(C)FC applications. Jin et al. [13] investigated the AC application of CO2 as a working fluid for a ground coupled heat pump (GCHP), i.e. a CO2 chiller with heat pump options. The system utilises a combination of ambient air and ground as a heat sink in AC mode. Simulation results show that the hybrid system COP would be increased by 8%~20% depending on the capacity of the air-cooled gas cooler, comparing with a standard CO2 chiller unit. An optimal averaged system COP of 3.45 is obtained when the air-cooled capacity is 30%~40%. An optimal operating pressure in the gas cooler is obtained at around 80bar at high ambient temperatures for the investigated system. The influence of the borehole depth was analysed and a heat flux range with 20 W/m~30W/m for the concerned borehole is 2 Press release, 19.12.2013, of the Japan Refrigeration and Air Conditioning Industry Association 9PDF Image | R744 ejector technology

PDF Search Title:

R744 ejector technologyOriginal File Name Searched:

Hafner_2016-745_032157.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |