PDF Publication Title:

Text from PDF Page: 002

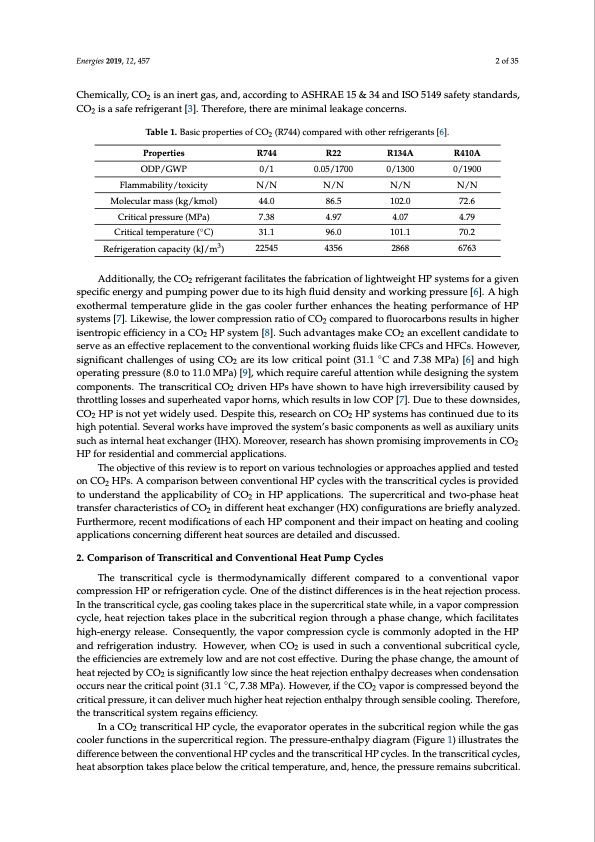

Energies 2019, 12, 457 2 of 35 Chemically, CO2 is an inert gas, and, according to ASHRAE 15 & 34 and ISO 5149 safety standards, CO2 is a safe refrigerant [3]. Therefore, there are minimal leakage concerns. Table 1. Basic properties of CO2 (R744) compared with other refrigerants [6]. Properties ODP/GWP Flammability/toxicity Molecular mass (kg/kmol) Critical pressure (MPa) Critical temperature (◦C) Refrigeration capacity (kJ/m3) R744 R22 0/1 0.05/1700 N/N N/N 44.0 86.5 7.38 4.97 31.1 96.0 22545 4356 R134A 0/1300 N/N N/N 102.0 72.6 4.07 4.79 101.1 70.2 2868 6763 R410A 0/1900 Additionally, the CO2 refrigerant facilitates the fabrication of lightweight HP systems for a given specific energy and pumping power due to its high fluid density and working pressure [6]. A high exothermal temperature glide in the gas cooler further enhances the heating performance of HP systems [7]. Likewise, the lower compression ratio of CO2 compared to fluorocarbons results in higher isentropic efficiency in a CO2 HP system [8]. Such advantages make CO2 an excellent candidate to serve as an effective replacement to the conventional working fluids like CFCs and HFCs. However, significant challenges of using CO2 are its low critical point (31.1 ◦C and 7.38 MPa) [6] and high operating pressure (8.0 to 11.0 MPa) [9], which require careful attention while designing the system components. The transcritical CO2 driven HPs have shown to have high irreversibility caused by throttling losses and superheated vapor horns, which results in low COP [7]. Due to these downsides, CO2 HP is not yet widely used. Despite this, research on CO2 HP systems has continued due to its high potential. Several works have improved the system’s basic components as well as auxiliary units such as internal heat exchanger (IHX). Moreover, research has shown promising improvements in CO2 HP for residential and commercial applications. The objective of this review is to report on various technologies or approaches applied and tested on CO2 HPs. A comparison between conventional HP cycles with the transcritical cycles is provided to understand the applicability of CO2 in HP applications. The supercritical and two-phase heat transfer characteristics of CO2 in different heat exchanger (HX) configurations are briefly analyzed. Furthermore, recent modifications of each HP component and their impact on heating and cooling applications concerning different heat sources are detailed and discussed. 2. Comparison of Transcritical and Conventional Heat Pump Cycles The transcritical cycle is thermodynamically different compared to a conventional vapor compression HP or refrigeration cycle. One of the distinct differences is in the heat rejection process. In the transcritical cycle, gas cooling takes place in the supercritical state while, in a vapor compression cycle, heat rejection takes place in the subcritical region through a phase change, which facilitates high-energy release. Consequently, the vapor compression cycle is commonly adopted in the HP and refrigeration industry. However, when CO2 is used in such a conventional subcritical cycle, the efficiencies are extremely low and are not cost effective. During the phase change, the amount of heat rejected by CO2 is significantly low since the heat rejection enthalpy decreases when condensation occurs near the critical point (31.1 ◦C, 7.38 MPa). However, if the CO2 vapor is compressed beyond the critical pressure, it can deliver much higher heat rejection enthalpy through sensible cooling. Therefore, the transcritical system regains efficiency. In a CO2 transcritical HP cycle, the evaporator operates in the subcritical region while the gas cooler functions in the supercritical region. The pressure-enthalpy diagram (Figure 1) illustrates the difference between the conventional HP cycles and the transcritical HP cycles. In the transcritical cycles, heat absorption takes place below the critical temperature, and, hence, the pressure remains subcritical.PDF Image | Recent Advances in Transcritical CO2 (R744) Heat Pump System

PDF Search Title:

Recent Advances in Transcritical CO2 (R744) Heat Pump SystemOriginal File Name Searched:

energies-12-00457.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |