PDF Publication Title:

Text from PDF Page: 033

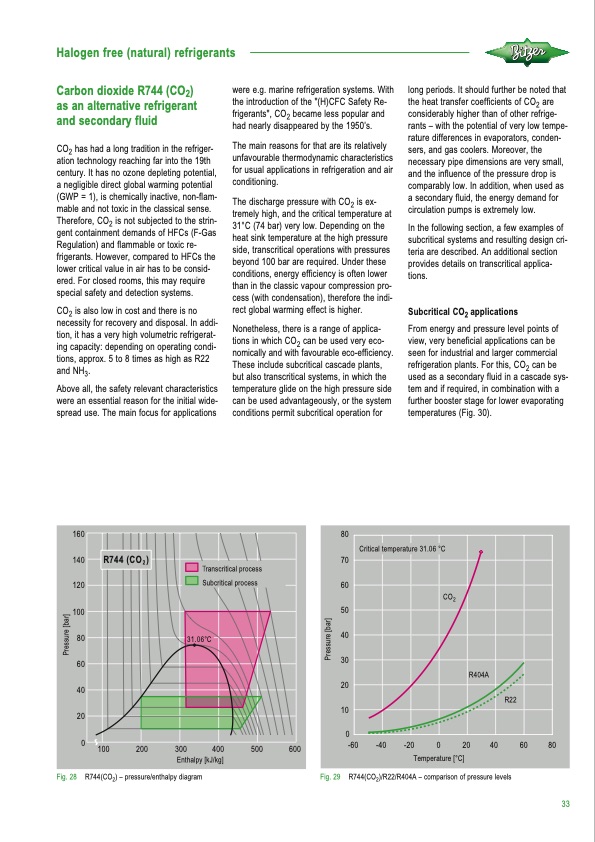

Halogen free (natural) refrigerants Carbon dioxide R744 (CO2) as an alternative refrigerant and secondary fluid CO2 has had a long tradition in the refriger- ation technology reaching far into the 19th century. It has no ozone depleting potential, a negligible direct global warming potential (GWP = 1), is chemically inactive, non-flam- mable and not toxic in the classical sense. Therefore, CO2 is not subjected to the strin- gent containment demands of HFCs (F-Gas Regulation) and flammable or toxic re- frigerants. However, compared to HFCs the lower critical value in air has to be consid- ered. For closed rooms, this may require special safety and detection systems. CO2 is also low in cost and there is no necessity for recovery and disposal. In addi- tion, it has a very high volumetric refrigerat- ing capacity: depending on operating condi- tions, approx. 5 to 8 times as high as R22 and NH3. Above all, the safety relevant characteristics were an essential reason for the initial wide- spread use. The main focus for applications were e.g. marine refrigeration systems. With the introduction of the "(H)CFC Safety Re- frigerants", CO2 became less popular and had nearly disappeared by the 1950’s. The main reasons for that are its relatively unfavourable thermodynamic characteristics for usual applications in refrigeration and air conditioning. The discharge pressure with CO2 is ex- tremely high, and the critical temperature at 31°C (74 bar) very low. Depending on the heat sink temperature at the high pressure side, transcritical operations with pressures beyond 100 bar are required. Under these conditions, energy efficiency is often lower than in the classic vapour compression pro- cess (with condensation), therefore the indi- rect global warming effect is higher. Nonetheless, there is a range of applica- tions in which CO2 can be used very eco- nomically and with favourable eco-efficiency. These include subcritical cascade plants, but also transcritical systems, in which the temperature glide on the high pressure side can be used advantageously, or the system conditions permit subcritical operation for long periods. It should further be noted that the heat transfer coefficients of CO2 are considerably higher than of other refrige- rants – with the potential of very low tempe- rature differences in evaporators, conden- sers, and gas coolers. Moreover, the necessary pipe dimensions are very small, and the influence of the pressure drop is comparably low. In addition, when used as a secondary fluid, the energy demand for circulation pumps is extremely low. In the following section, a few examples of subcritical systems and resulting design cri- teria are described. An additional section provides details on transcritical applica- tions. Subcritical CO2 applications From energy and pressure level points of view, very beneficial applications can be seen for industrial and larger commercial refrigeration plants. For this, CO2 can be used as a secondary fluid in a cascade sys- tem and if required, in combination with a further booster stage for lower evaporating temperatures (Fig. 30). ��� ��� ��� ��� �� �� �� �� � ��� ��� ��� ��� �������� ������� ��� ��� ���� ���� � 2 ������� T������������ ������� ����������� ������� �� �� �� �� �� �� �� �� � ��� ��� ��� � �� �� �� �� ����������� ���� �������� ����������� ����� �� ��� ����� ��� Fig. 28 R744(CO2) – pressure/enthalpy diagram Fig. 29 R744(CO2)/R22/R404A – comparison of pressure levels 33 �������� ����� �������� �����PDF Image | REFRIGERANT REPORT 21

PDF Search Title:

REFRIGERANT REPORT 21Original File Name Searched:

A-501-21_EN.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |